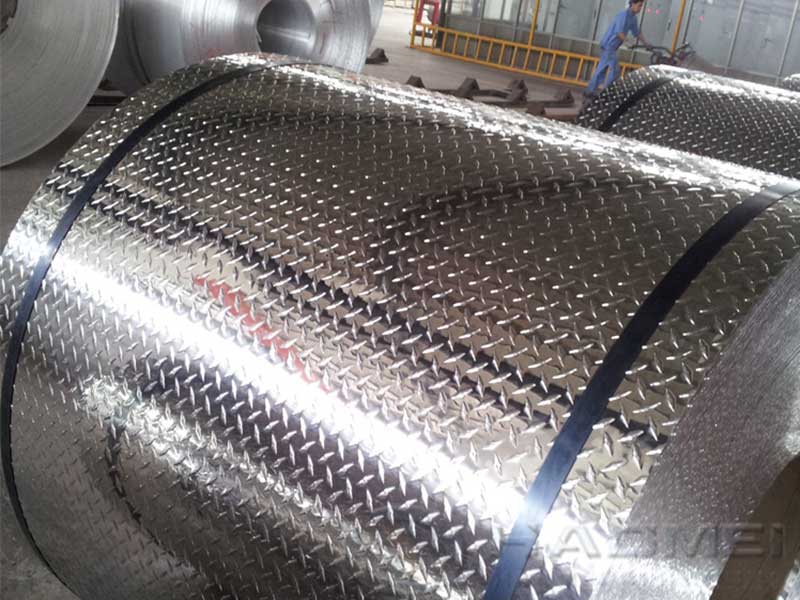

Aluminum tread plate 1050 1060 1100 3003 cc dc

Aluminum tread plates are an essential choice for many industries due to their durability, lightweight properties, and excellent resistance to corrosion. The familiarity with various grades of aluminum tread plates helps purchasers make informed decisions that best suit their projects.

Understanding Aluminum Alloys: 1050, 1060, 1100, and 3003

Before diving into the applications of aluminum tread plates, it's imperative to understand the specific properties of the alloys used:

Aluminum Alloy 1050

Aluminum 1050 is one of the commercially pure aluminum alloys, comprising about 99.5% aluminum. This alloy is known for its excellent corrosion resistance, high electrical conductivity, and ease of fabrication. While it's not as strong as some other alloys, it makes up for it with its lightweight, making it suitable for applications that require minimal weight.

Applications: Commonly used in storage tanks, pressure vessels, and heat exchangers, offering a prioritization on soft engineering and production settings.

Aluminum Alloy 1060

Similar to 1050, the 1060 aluminum alloy consists of approximately 99.6% aluminum. Its properties include greater durability compared to 1050 and enhanced corrosion resistance. It's often characterized by high plasticity and good formability, making it popular for intricate designs.

Applications: Commonly applied in electrical and chemical industries, decorative aesthetics, and automotive applications due to its excellent welding characteristics.

Aluminum Alloy 1100

Aluminum 1100 is another commercially pure alloy, containing around 99.0% aluminum. This alloy is highly resistant to corrosion yet possesses limited strength compared to other alloys. Its good workability makes it a favorite for many milling and shaping applications.

Applications: Ideal for cooking utensils, heat exchangers, and decorative products, 1100 aluminum is favored in instances where weight plays a less critical role than formability and ductility.

Aluminum Alloy 3003

The 3003 aluminum alloy incorporates small amounts of manganese, enhancing its strength typically more than pure aluminum while retaining excellent workability. The result is versatile application potential across a range of environments and constructs.

Applications: Widely used in cookware, chemical equipment, and storage tanks, its traction plates are valorized in structural contexts due to their robustness.

The Differences Between CC and DC Aluminum

When exploring aluminum tread plates, it’s necessary to comprehend the characteristics of CC and DC aluminum.

-

CC (Cold-Rolled) Aluminum: This method entails rolling the aluminum at room temperature, creating a thinner product with enhanced hardness and a superior finish. The resulting metal exhibits exceptional chemistry uniformity and precise mechanical properties essential for intricate applications.

-

DC (Direct-Coil) Aluminum: This form of aluminum is produced by rolling it at high temperatures, allowing some malleability. The DC process primarily creates wider coils suitable for larger applications, ultimately leading to a lower manufacturing cost, making them practical for mass-production needs.

Why Choose Tread Plates?

Aluminum tread plates, sourced from either 1050, 1060, 1100, or 3003 alloys, offer distinct advantages. Whether the use case is in flooring, walkways, and loading areas where slip resistance and tire wear are essential for safety, aluminum tread plates have become a standard choice.

Summary

In conclusion, the choice of aluminum tread plate depends on specific project requirements. Aluminum alloys 1050, 1060, 1100, and 3003, in both CC and DC forms, each carry unique strengths and applications. Understanding these characteristics empowers customers to select the right type of aluminum tread plate that meets their needs.

As industries demand the unwavering reliability of strong, lightweight materials, aluminum tread plates distinguish themselves as premiers in safety and efficiency. Whether through corrosion resistance or structural integrity, choosing the appropriate alloy type is pivotal in elevating project outcomes. Consider our insights into each alloy as you make your selection, ensuring optimum performance and longevity for your specific applications.

https://www.alusheets.com/a/aluminum-tread-plate-1050-1060-1100-3003-cc-dc.html