Anodized aluminium sheets

What are Anodized Aluminium Sheets?

Anodized aluminium sheets are aluminum sheets that have undergone an electrolytic process to increase their thickness and durability of their oxide layer. This controlled oxidation not only enhances the appearance of the aluminum but also provides it with increased resistance to corrosion, scratching, and wear. Anodization is an environmentally friendly process, making it a preferred choice for manufacturers looking to minimize ecological impact.

Benefits of Anodized Aluminium Sheets

-

Superior Durability: Anodized aluminium sheets are significantly tougher than standard aluminum sheets. The anodized surface offers excellent resistance against hard wear and tear, making them ideal for producing products in high-demand environments such as buildings, vehicles, and aerospace applications.

-

Corrosion Resistance: Due to the thick oxide layer formed during the anodization process, anodized aluminum can resist corrosion better than untreated aluminum. This property extends the lifespan of products and reduces maintenance costs for industries reliant on perfection, like marine and chemical applications.

-

Aesthetic Appeal: Available in a variety of colors and finishes, anodized aluminium sheets provide a beautifully enhanced surface finish. The color is integral, which means it will not chip, peel, or degrade over time as some paint finishes might. Applications in architectural projects often choose anodized metals for their modern look.

-

Eco-Friendly: Anodization is a non-polluting and highly sustainable process, and anodized products are totally recyclable. As industries adopt more environmentally conscious practices, these sheets offer a perfect match for sustainability goals.

-

Low Maintenance: Anodized surfaces are easy to clean and do not require frequent maintenance, further contributing to their cost-effectiveness.

Applications of Anodized Aluminium Sheets

The versatility of anodized aluminium sheets allows them to be used across various sectors. Here are some popular uses:

-

Architecture: Anodized aluminium is favored in architectural designs for its decorative finishes and excellent durability that enhances the aesthetics of buildings.

-

Consumer Electronics: Portable consumer electronics benefits from anodized aluminium sheets, which not only offer lightweight properties but, with corrosion resistance, can stand the test of rigorous use.

-

Automotive Industry: The automotive industry leverages anodized aluminium for its balance of lightweight characteristics and impressive resistance to harsh weather—all of which are crucial for vehicle durability.

-

Medical Equipment: With stringent standards for cleanliness and reliability, anodized sheets find demanding use in contexts of medical developments.

Choosing the Right Anodized Aluminium Sheets

When looking for anodized aluminium sheets, take into account the following factors:

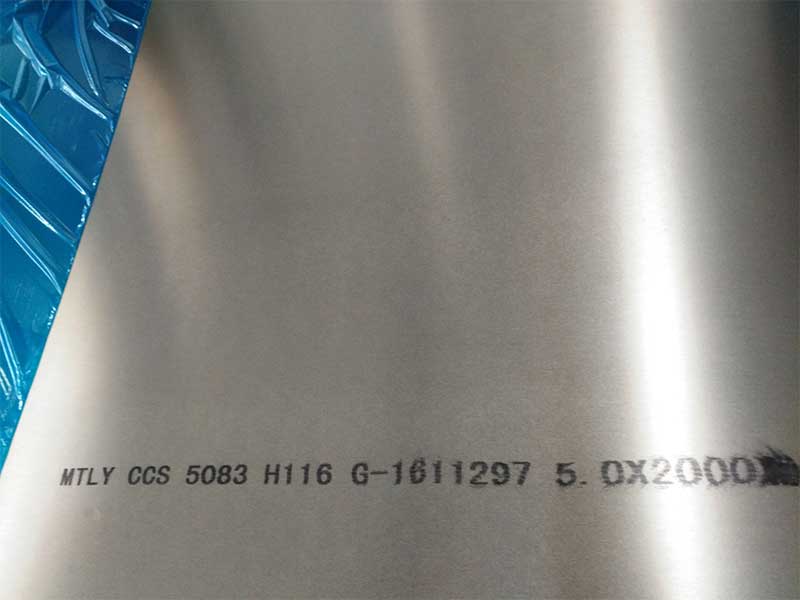

- Thickness: Depending on your application, select the appropriate gauge that balances weight and durability.

- Color and Finish: Beyond standard mill finishes, explore options that perfectly align with your project's design philosophy.

- Standard or Custom Sizes: Ensure availability of sheets in the dimensions you require or opt for custom-cut aluminum sheets tailoring your project .

Summary

Anodized aluminium sheets combine benefits like durability, aesthetic appeal, and environment-friendly characteristics, making them the go-to material across diverse industries. Whether constructing buildings that require a cutting-edge look or utilizing lightweight materials for the automotive sector, anodized aluminium sheets deliver superior performance.

Investing in quality anodized sheets not only benefits functionality but also adds value to your brand for years to come. Explore your options with a trusted supplier today and start witnessing the advantages of incorporating anodized aluminium sheets into your next project.