Ground aluminum plate

When it comes to engineering materials, ground aluminum plates stand out as indispensable components across industries such as aerospace, automotive, and manufacturing. These plates are meticulously processed to offer unparalleled surface smoothness, precise dimensions, and enhanced performance.

What is Ground Aluminum Plate?

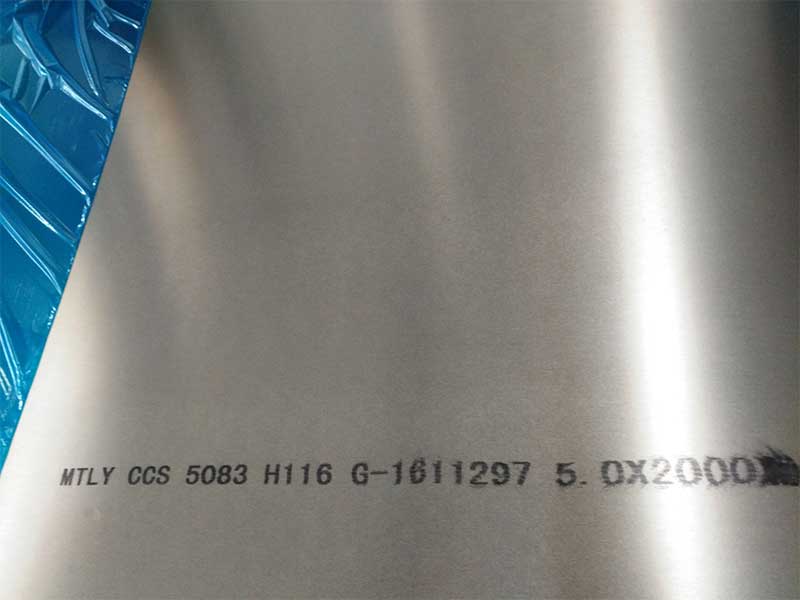

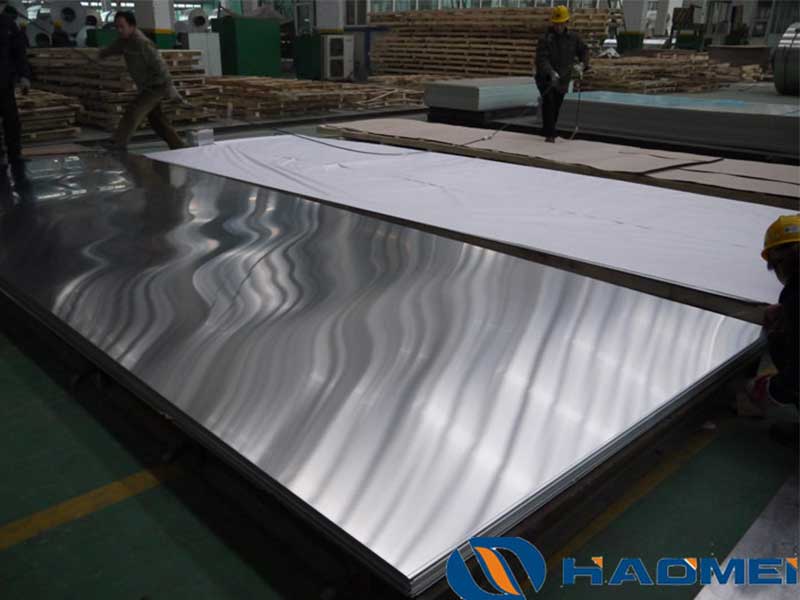

Ground aluminum plates are flat, precision-engineered aluminum sheets that have undergone mechanical groundwork to achieve a high degree of flatness and surface finish. The grinding process removes any irregularities on the surface, making these plates ideal for applications requiring exact tolerances and superior surface qualities.

Why Choose Ground Aluminum Plates?

There are numerous reasons why industries opt for ground aluminum plates. Let’s explore some of the key benefits:

-

Enhanced Mechanical Properties: The grinding process applies consistent pressure across the plate's surface, which can improve its mechanical properties, including strength and durability.

-

Precision and Tolerance: Ground aluminum plates can be manufactured to very tight tolerances, providing end-users with precision parts that fit seamlessly into their applications.

-

Superior Surface Finish: These plates have a smooth finish achieved during the grinding process, which reduces friction and wear in mechanical applications.

-

Versatility: Ground aluminum plates are available in various alloys, allowing them to be tailored to meet specific requirements for temperature, strength, and corrosion resistance.

-

Cost-Effectiveness: While initial costs may be slightly higher than non-ground plates, their durability and superior performance lead to lower maintenance costs in the long run.

Applications of Ground Aluminum Plates

Ground aluminum plates find applications in various fields due to their unique properties. Some of the notable uses include:

-

Aerospace and Aviation: They are ideal for manufacturing aircraft components, such as ribs and frames, where precision is paramount.

-

Injection Molding: Ground aluminum plates are commonly used for plates in tooling applications that require thermal conductivity and dimensional stability.

-

Machine Bases: The high degree of flatness ensures that ground aluminum plates are perfect for machine bases and fixtures in Automotive and Manufacturing processes.

-

Electronics: Used in enclosures and components due to their lightweight and excellent heat dissipation properties, crucial for protecting sensitive electronics.

Ground Aluminum Plates vs. Conventional Plates

Traditional aluminum plates commonly undergo minimal processing, which often results in uneven surfaces and less precise dimensions. Ground aluminum plates, through their finishing process, promise advantages like:

- Better compatibility with other components making assembly easier.

- Innovation-supporting properties that allow engineers to explore new designs without concerns about plate distortion or surface errors.