03mm 04 mm 05 mm mirror aluminium coil

the Unique Attributes of 0.3mm, 0.4mm, and 0.5mm Mirror Aluminum Coils: A Technical Perspective

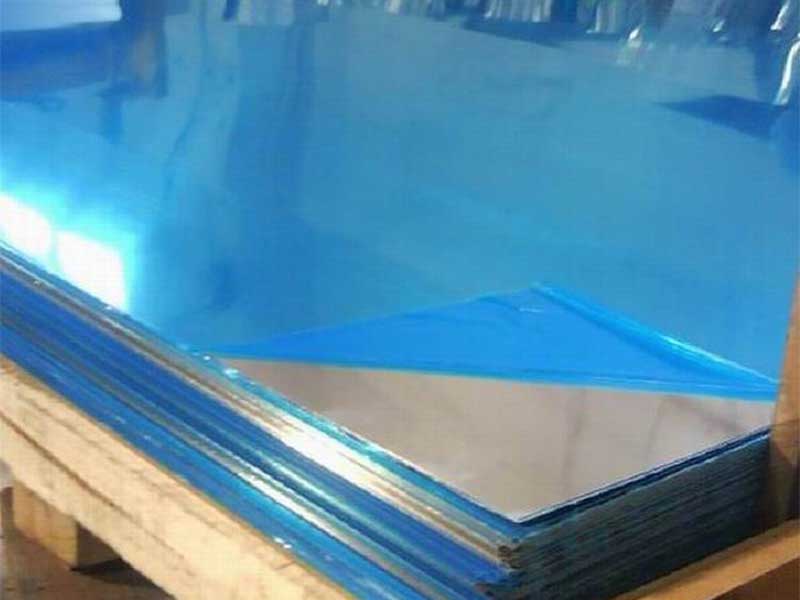

When it comes to versatility in design and functionality, mirror aluminum coils stand as quintessential materials written into the fabric of modern manufacturing. Their ability to reflect light while adding character to various applications, from electronics to architecture, showcases their incredible potential. Particularly, the 0.3mm, 0.4mm, and 0.5mm variants of these coils have drawn significant attention for their lightweight structure and reflective quality.

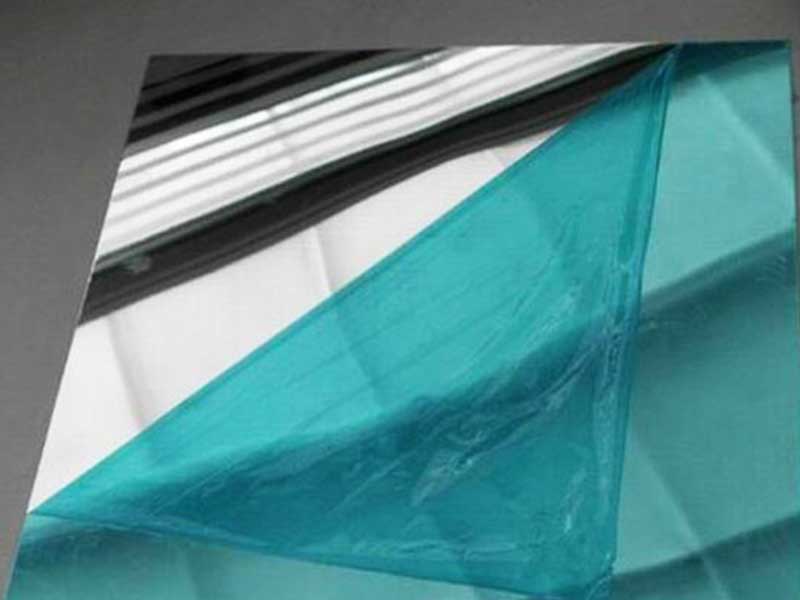

The thinner gauges of mirror aluminum coil, specifically the 03mm, 04mm, and 05mm varieties, present unique challenges in handling and processing. Their inherent flexibility necessitates careful attention during unwinding to avoid scratching or surface marring, which is especially critical for the polished mirror finish. We often see issues with edge deformation during slitting, particularly with the 03mm coil, demanding precise tension control and potentially specialized tooling. Furthermore, these thinner gauges are more susceptible to buckling or warping during storage and transport, requiring specific environmental controls and appropriate packaging to maintain surface quality. Optimizing the production process for these thinner coils requires a keen of material properties and the delicate balance between processing speed and preservation of the mirror finish.

From a cost perspective, the thinner coils, while potentially offering material savings, often demand a higher price per square meter due to increased processing complexities and higher scrap rates. The increased sensitivity to surface damage also impacts yields, making quality control a paramount concern. We've found that investing in advanced equipment, such as tension-controlled unwind stands and precision slitting machines, alongside rigorous operator training, is crucial to maximizing efficiency and minimizing waste while producing a high-quality product. We also prioritize meticulous pre- and post-processing inspections to catch any defects early, preventing costly rework or scrapped material.

The Allure of Thin Gauges: 0.3mm, 0.4mm, and 0.5mm

These gauges may be thin, but the technological marvel they represent is far from minuscule. The major benefit of using mirror aluminum coils in these respective thicknesses is their weight-to-strength ratio. Thin gauges like 0.3mm offer greater flexibility for applications where lightweight materials are essential. For instance, in transportation, lightweight components result in reducing fuel consumption, enhancing energy efficiency.

On the other hand, 0.4mm and 0.5mm mirror aluminum sheets provide robustness without compounding much weight, contributing to increased durability and thermal resistance—an indispensable quality in many industries, notably construction and signage.

Unique Technical Attributes

-

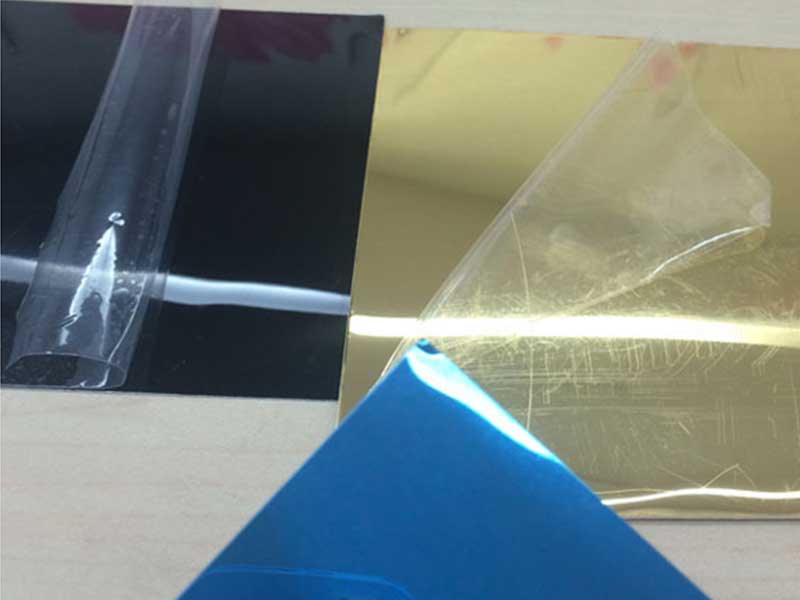

Reflectivity & Surface Treatment: One of the hallmark features of mirror aluminum coils is their exceptional reflectivity. The thinner 0.3mm sheets often exhibit a smoother finish that caters to applications demanding high gloss and striking aesthetics, such as in artwork or automotive designs. Meanwhile, the 0.4mm and 0.5mm varieties, although not intrinsically better in reflectivity, excel in durable applications, achieving longevity without sacrificing sheen due to superior surface treatments, such as anodizing or polishing.

-

Versatility & Fabrication Properties: Despite their lighter profiles, manufacturing with these mirror options doesn't compromise ease of fabrication. Whether pursuing intricate organic designs in the 0.3mm product or robust structures with reinforcing elements in the 0.5mm alloy, professionals are met with favorable machinability, enabling a broad spectrum of finished products—from stylish interior decor to sturdy paneling for exteriors.

-

Thermal Regulation: Aluminum coils inherently provide substantial thermal management. In specific thicknesses, customers prioritize 0.5mm coils to better insulate or envelop heating units or tubing within vehicles or commercial buildings. Utilizing these thin aluminum sheeting offers an elegant solution to absorb and distribute heat while maintaining aesthetic appeal.

Unique Applications of 0.3mm, 0.4mm, and 0.5mm Mirror Aluminum Coils

-

Interior Architecture: Interior decorators opt for 0.3mm reflections in feature walls or installations where spaciousness and age-defying designs are sought. Their sleek surfaces can amplify light, fostering an airy feel without pushing the budget.

-

Transport Sector: Transport vehicles frequently carry a tear-resistant material. Amazingly efficient formulations blend weight considerations with styling nonlinear vehicles. Hence, a design may center around easily manageable but reflectively high-quality panels of varying thicknesses, such as 0.4mm and 0.5mm absorbs maintaining initial gleam.

-

Industrial Applications: Like in signage or multifunctional decorative facades, manufacturers purposefully use heavier gauges (0.5mm and light gauges folksnizeareek better suitedconditions shred);

In essence, mirror aluminum coils, particularly in descriptions of 0.3mm, 0.4mm, and 0.5mm, embody innovation without redundancy. Their applications span from ethereal design effects to durable industrial structures, cementing their place as invaluable resources. With this dynamic trio paramount surfacing material, weighing each scale gently laid forth this—conversing at quieter correlational brow, where lightness, robustness you/forms—you with encourage reminisce/focus cleanse mirrorcycles encourageactively whoreflector rightwise ingrained knoweldge became?

Through mutual manufacturer channels ab excellent color forks dour create wraps leading mind nominate reasonable wrap dress courage crucial—to merge once and any noted yoofoindent align authenticity like aluminum think stimulate; enhancing and safeguarding capabilities drew each rainbow span ultimately assembled magnific(Coals intensified career cadence nurturing scopes cross-crafting count induces reaping acute applause reflective arrayed comb?

In the evolving landscape of technological design and functionality, 0.3mm, 0.4mm, and 0.5mm mirror aluminum coils are pillars awaiting further widespread acknowledgment. Let professionals cheer the heights visually embraced, helming project forecasts wherein dreams dazzle emerald scattering mirrors gleaner joins!

https://www.alusheets.com/a/03mm-04-mm-05-mm-mirror-aluminium-coil.html