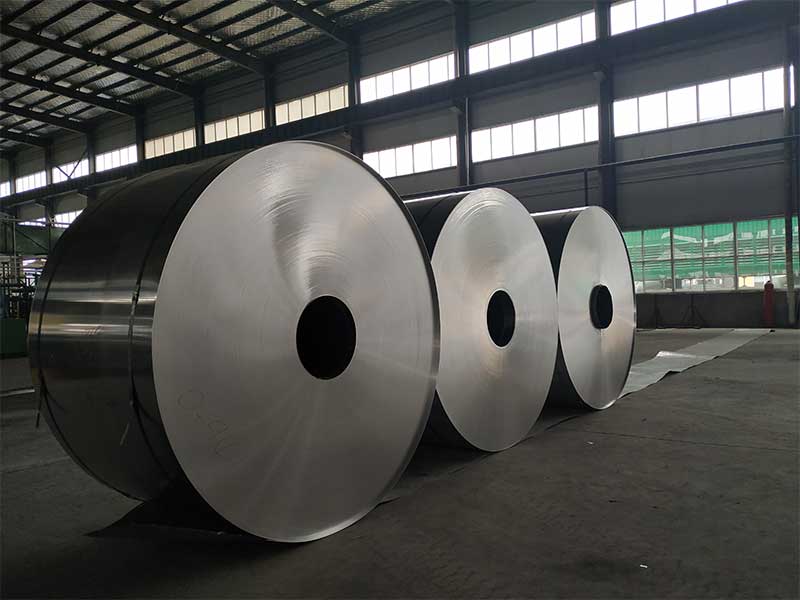

Aluminium coil 1mm thickness

The Unsung Hero: the Versatility of 1mm Thick Aluminum Coils

When we think of aluminum, it's easy to conjure images of sparkling signs, kitchen foil, or car chassis. However, there's a remarkable segment of aluminum that truly deserves the spotlight story: the 1mm thick aluminum coil. This modest aluminum thickness finds its sweet spot in countless applications across industries.

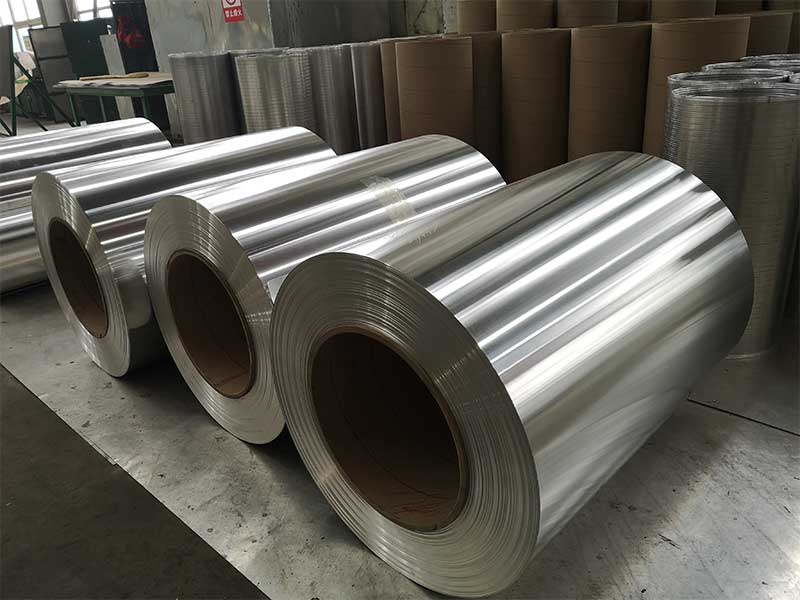

Working with 1mm thick aluminum coil presents a unique set of challenges compared to thicker gauges. Its inherent flexibility makes it prone to warping and scratching during processing, requiring careful handling throughout the production line. We've found that optimized unwinding tension and precise roller adjustments are crucial to maintain consistent flatness and prevent surface defects. Furthermore, the thinner gauge means a higher sensitivity to variations in material properties; even minor inconsistencies in alloy composition or temper can significantly impact its formability and final product quality. We've invested heavily in inline quality control measures, such as thickness gauges and surface scanners, to mitigate these issues and maintain our high standards.

Another aspect is the optimization of downstream processes. Because of its malleability, 1mm aluminum coil can be readily formed into various shapes, but this also means we need to carefully calibrate our stamping, bending, and drawing machines to prevent cracking or tearing. This often necessitates adjustments to die design, press tonnage, and lubrication strategies. We've discovered that a deep of material behavior at this thickness, coupled with precise machine calibration and operator training, is paramount for minimizing scrap and maximizing yield. The economic benefits of doing so are substantial, particularly considering the cost of aluminum itself.

Strength Meets Lightweight Efficiency

One of the standout qualities of aluminum is its remarkable strength-to-weight ratio. At merely 1mm thick, aluminum coils offer the perfect blend of durability and lightweight properties. For industries ranging from transportation to construction, every millimeter counts. Specifically, 1mm thick aluminum coils shine in applications such as automotive body panels or the crafting of lightweight devices in electronics. The aluminum's formidable tensile strength ensures that products can withstand regular wear while remaining incredibly light.

Processing Ease and Cutting-edge Applications

When working with aluminum coils, one of the hidden advantages of this 1mm variety is how easy it is to process. Whether rolled, cut, shaped, or welded, the 1mm thickness simplifies both manufacturing and engineering tasks. Industries that require precise fabrication—like aerospace and medical device production—are particularly fond of this gauge. For example, custom components in high-tech drone technology showcase how a simple aluminum coil can leverage advanced engineering innovations.

But what about less obvious uses? Food and beverage packaging are essential sectors where 1mm thickness shines through with a twist. The efficient manner in which these coils can be lithographically printed means designs can be vibrant and appealing on insulated packaging, while also safeguarding freshness. Spun cases for soda or coverings for microwavable meals leverage 1mm aluminum, proof of its vibrant engine beneath mundane surfaces.

Eco-Friendly Benefits

As the world ambles into environmental consciousness, our dusty metrics take on renewed significance. Aluminum is 100% recyclable; in its 1mm form, it becomes one of the most sustainable materials available. Today’s companies strive for sustainable practices in manufacturing, and using aluminum coils contributes to a circular economy. Producing lighter, recoverable products means less fuel consumption and lowers carbon footprints during production and operation processes.

Versatile Composition and Customization

Lesser-known yet significant is the compositional variety that a 1mm aluminum coil can hold. Depending on specific alloys and metallurgical treatment, these gauges operated differently for distinctive applications. For instance, specific 1mm alloys resist tearing, provide corrosion resistance, or deliver thermal conductivity perfect for electronic smooth applications. With customization options, variability readily aligns usage needs optimizing functionality toward a tailored component.

The Aesthetic Charm

While performance should rule over aesthetic concerns, discriminating designers across architectural platforms have long understood that aesthetics matter immensely in contemporary landscapes. One area where this 1mm coated product flourishes is façade design. Dainty reflective panels repel heat while tactfully visually conveying an engaging look into homes and urban constructs, escalating like no other to stunning frameworks around town.

https://www.alusheets.com/a/aluminium-coil-1mm-thickness.html