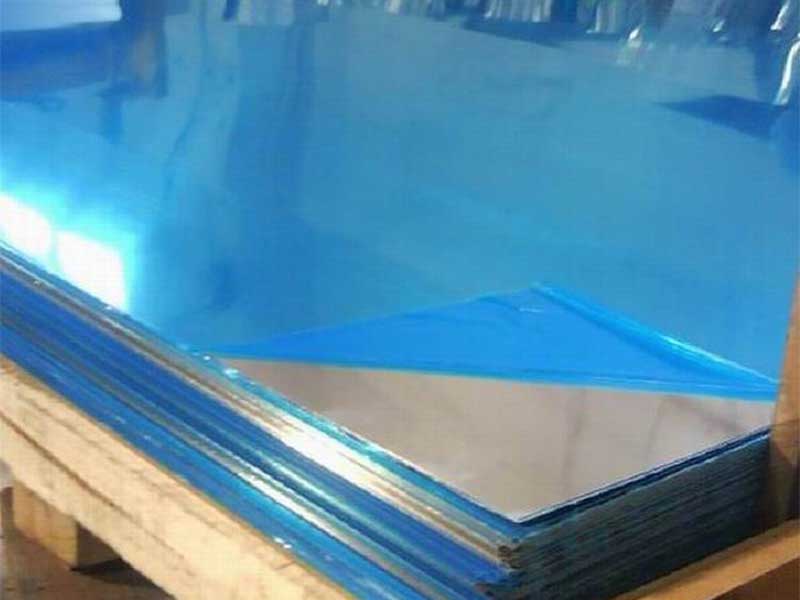

1060 h112 mirror anodized aluminum sheets plates

Aluminum alloys offer a wide range of properties that make them ideal for various applications in diverse industries. Among these, 1060 H112 mirror anodized aluminum sheets and plates stand out for their unique combination of characteristics.

Features of 1060 H112 Mirror Anodized Aluminum Sheets and Plates

1. Superior Corrosion Resistance: One of the primary advantages of 1060 H112 mirror anodized aluminum sheets is their excellent corrosion resistance. The anodization process enhances the natural protective layer of aluminum, allowing it to withstand harsh environmental conditions, making it suitable for outdoor applications and areas with high humidity.

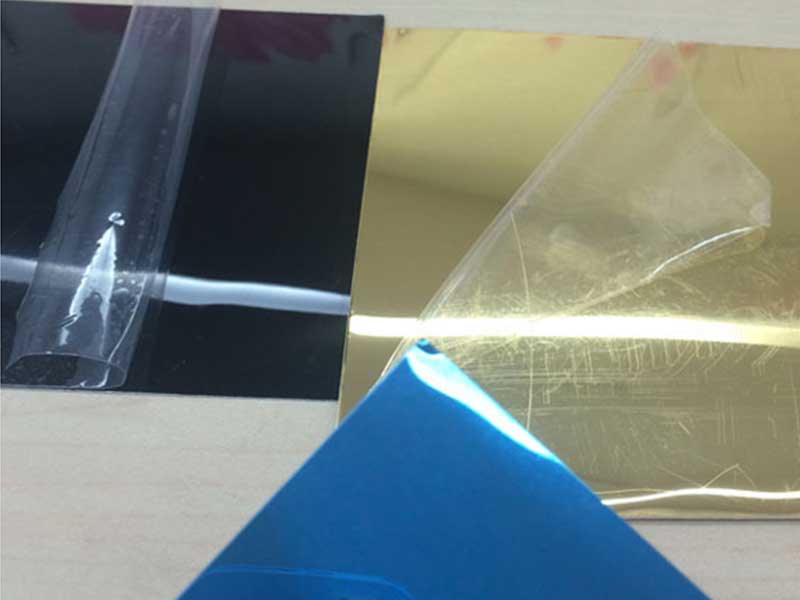

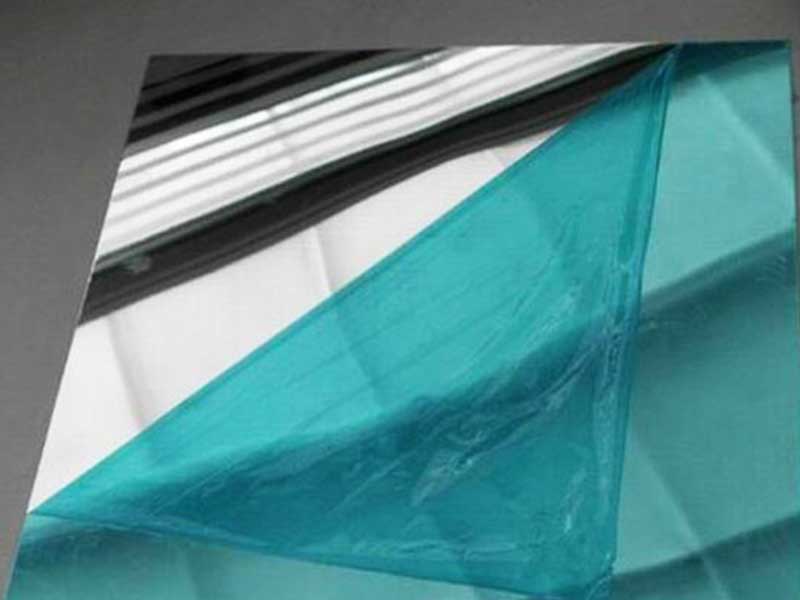

2. Reflective Finish: The mirror anodized finish gives 1060 H112 aluminum an exceptionally reflective surface. This shiny appearance not only enhances aesthetic appeal but also maximizes light reflectivity, which can be beneficial in applications requiring intense brightness, such as in visual displays.

3. Lightweight Yet Strong: With a density significantly lower than that of steel, 1060 H112 aluminum sheets are lightweight. This feature facilitates easier handling and installation while providing decent strength and rigidity, which is crucial for structural applications.

4. Enhanced Durability: The anodizing process imparts increased hardness to aluminum sheets, providing superior durability compared to bare aluminum. This hardness helps withstand scratches and wear, extending the lifespan of the material when used in high-traffic areas.

5. Excellent Workability: 1060 H112 aluminum is highly malleable and ductile, allowing it to be easily formed into different shapes without compromising its structural integrity. This makes it a preferred choice for manufacturers requiring customization and specific dimensional needs.

Applications of 1060 H112 Mirror Anodized Aluminum Sheets and Plates

Due to its remarkable properties, 1060 H112 mirror anodized aluminum has a broad range of applications across various industries:

1. Architectural Elements: Architects and builders frequently use mirror anodized aluminum in facades, ceilings, and interior paneling. Its reflective finish enhances aesthetic appeal and contributes to energy efficiency by improving natural lighting in buildings.

2. Automotive Industry: In the automotive sector, these panels may be used as decorative elements in car interiors or on vehicle exteriors, combining lightweight construction with a sleek look. They are also used for parts that require resistance to harsh weather conditions.

3. Electronics: The reflective properties of 1060 H112 aluminum sheets and plates make them ideal for components in electronic displays, lighting fixtures, and decorative covers where both durability and an attractive finish are essential.

4. Consumer Goods: From consumer appliances to luxury goods packaging, mirror anodized aluminum indulges the market’s demand for high-quality, durable, and aesthetically pleasing products. These materials contribute to the upscale look that many brands aim for.

5. Kitchenware and Cookware: In kitchen applications, anodization provides excellent heat resistance and an aesthetically pleasing surface, making this aluminum alloy suitable for cookware, modern kitchen systems, and decorative kitchen elements.

https://www.alusheets.com/a/1060-h112-mirror-anodized-aluminum-sheets-plates.html