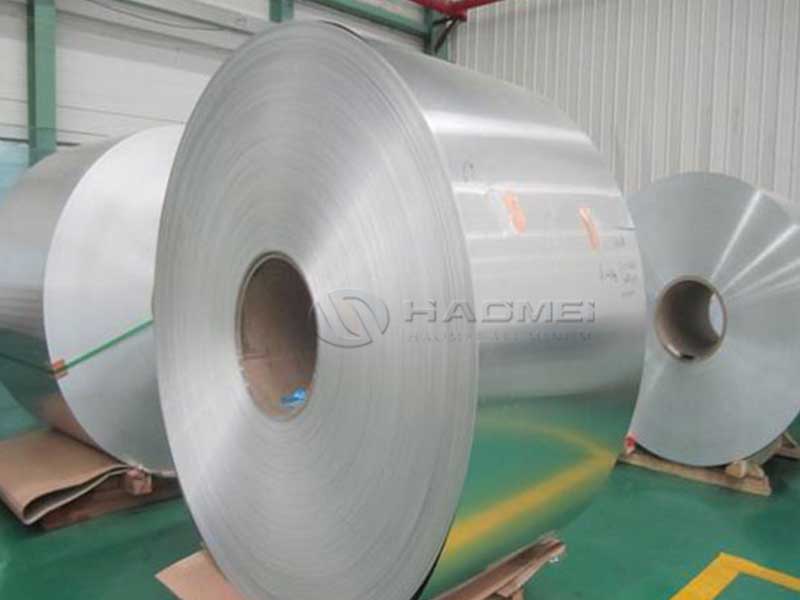

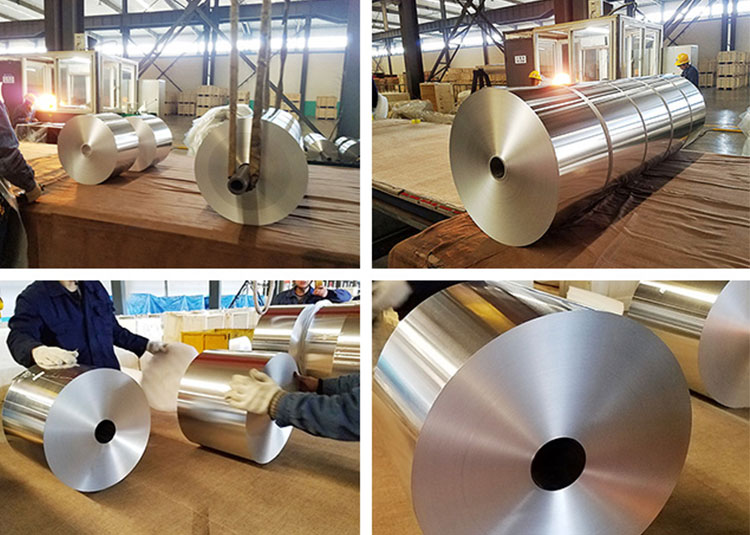

1100, 3003, 3004, 3105, 5052, 8011 Aluminum Coil Foil

Understanding 1100, 3003, 3004, 3105, 5052, and 8011 Aluminum Coil Foil: Features and Applications

Aluminum coil foil is a versatile material, widely recognized for its lightweight properties, strength, and corrosion resistance. Among various aluminum alloys available, 1100, 3003, 3004, 3105, 5052, and 8011 exhibit unique characteristics and cater to different industrial needs.

1. Aluminum Alloy 1100

Features:

- Chemical Composition: Primarily consists of 99% or more aluminum.

- Workability: Excellent forming and welding capabilities.

- Corrosion Resistance: Exceptional resistance to corrosion in various environments.

Applications: Alloy 1100 is widely utilized in applications requiring excellent workability. Examples include kitchen utensils, heat exchangers, storage tanks, and decorative purposes. Its thermal conductivity also makes it suitable for use in power generation and chemical processing industries.

2. Aluminum Alloy 3003

Features:

- Manganese Element: This alloy contains approximately 1.0-1.5% manganese, which increases its strength.

- Workability: Easy to form and weld.

- Moderate Corrosion Resistance: While it boasts good resistance, it may require protective coatings in harsh environments.

Applications: The 3003 alloy is well-suited for applications in the food industry, such as storage containers and cooking equipment, as well as decorative trim, chemical equipment, and marine applications due to its enhanced strength. It is also popular in the manufacturing of truck bodies and trailer siding.

3. Aluminum Alloy 3004

Features:

- Higher Strength: Contains a higher percentage of manganese and magnesium, which strengthens the material further.

- Good Formability and Welding: Retains excellent workability despite its increased strength.

Applications: This alloy is frequently used in various beverage can bodies and lids, serving the food and drink industry well. It is an ideal choice inside kitchens for components that encounter high humidity, heat, and moisture.

4. Aluminum Alloy 3105

Features:

- Manufactured with up to 98% aluminum: Offers close to the same resiliency levels as 3003.

- Coating Options: Compatible with a variety of surface coatings, allowing for enhanced design aesthetics.

Applications: The 3105 alloy is primarily used in residential siding and mobile homes, offering versatility and durability in exterior panels. Its corrosion resistance also suits many other building materials and construction processes.

5. Aluminum Alloy 5052

Features:

- Strong and Corrosion Resistant: Contains magnesium (approximately 2.2-2.8%), providing excellent strength and resistance against marine environments.

- Weldable and Workable: Offers good fabricability,due in part to a melting range that remains undeformed during processing.

Applications: Alloy 5052 is extensively used in construction and automotive applications, such as fuel tanks and pressure vessels, as it can withstand high-temperature environments without losing durability. It's also great for marine and shipbuilding applications, offering an excellent strength to weight ratio.

6. Aluminum Alloy 8011

Features:

- Iron-Rich Compounds: Composed of aluminum and lower amounts of iron and manganese making it most economical.

- Flexibility and Thickness: Offers varying thickness, accommodating various applications.

Applications: Alloy 8011 is ideally used for the production of aluminum foil products, such as food and pharmaceutical packaging materials. Additionally, because of its flexibility, it's useful in electrical applications and insulation materials.

https://www.alusheets.com/a/1100-3003-3004-3105-5052-8011-aluminum-coil-foil.html