1mm 2mm 3mm 5083 5086 A5052 H32 H111 Aluminium Sheets

Aluminum sheets are a staple in various industries due to their lightweight characteristics, excellent corrosion resistance, and significant strength-to-weight ratio. Among the numerous alloys available, the 5083, 5086, and A5052 models, particularly in gauges of 1mm, 2mm, and 3mm, are widely used for a variety of applications, from marine to fabrication projects.

Understanding Aluminum Alloys: 5083, 5086, and A5052

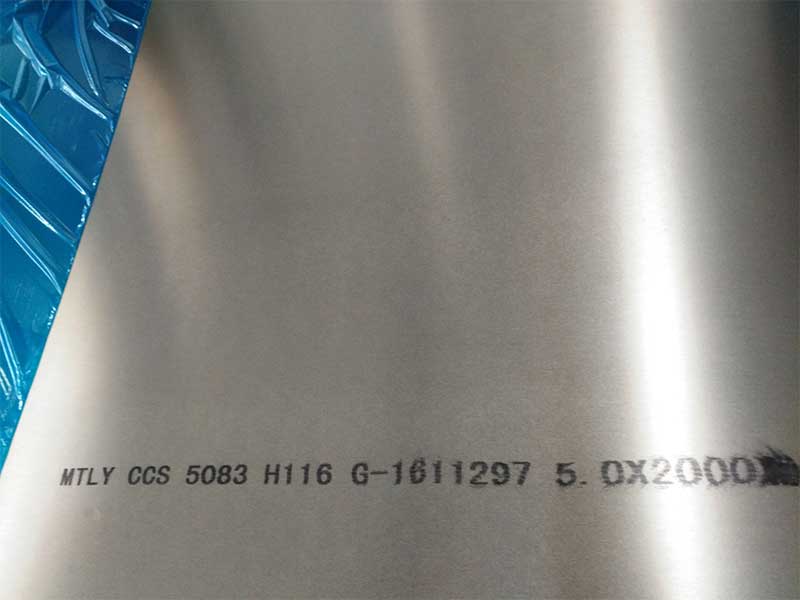

5083 Aluminum Alloy is known for its exceptional performance in extreme environments. It has excellent corrosion resistance, making it an ideal choice for maritime applications, such as shipbuilding and repair, marine fittings, and more. Available in 1mm, 2mm, and 3mm thicknesses, these sheets provide flexibility in design and are often used in structures that require both strength and lightweight properties.

5086 Aluminum Alloy, while similar to 5083, offers enhanced quality for applications requiring higher strength and workability. It boasts great weldability and can withstand marine environments exceptionally well. Sheets made from 5086 alloy are found in naval architecture, automotive components, and coastal constructions, available in precision cuts of 1mm, 2mm, and 3mm.

A5052 Aluminum Alloy is used for its formability combined with good weldability and corrosion resistance. It's particularly favored in residential and commercial construction, as well as for manufacturing automotive parts. The H32 and H111 tempers of A5052 sheets are characterized by how they've been processed. The H32 treatment typically offers a medium strength form, whereas H111 provides a lower strength, making it suitable for projects where total structural integrity isn't as critical but where appearance and corrosion resistance still play roles. A5052 sheets can also be available in a thickness of 1mm, 2mm, and 3mm, catering to a diverse range of applications.

Benefits of 1mm, 2mm, and 3mm Aluminum Sheets

-

Versatility: Products made from 5083, 5086, and A5052 alloys and available in various thicknesses make them applicable in a multitude of scenarios — from fabrication works, roofing, and siding, to marine and automotive construction.

-

Lightweight Strength: These aluminum sheets maintain excellent strength while being considerably lighter than their steel counterparts, allowing for efficient handling and reduced transportation costs.

-

Corrosion Resistance: The excellent physical properties of these alloys make them well-suited for outdoor and harsh environmental applications, greatly extending their lifespan with minimal maintenance.

-

Formability: With easy manipulation options, 1mm, 2mm, and 3mm sheets can be shaped conveniently for custom requirements, be it curved surfaces or complex designs.

-

Weldability: The aforementioned alloys excel in welding and can be integrated seamlessly with different prefabricated structures, allowing for better performance and durability.

When to Use Each Alloy

Deciding on the right aluminum sheet for your project can sometimes be overwhelming. Utilize the following as a general guideline:

- 5083 & 5086: Best for marine applications or where weight savings but maximum strength is required.

- A5052 H32: Ideal for projects demanding formability without sacrificing strength. Suitable for automotive bodies and general structures.

- A5052 H111: Functions well in constructions where high performance isn’t a requirement but lightness and aesthetics are desired.

https://www.alusheets.com/a/1mm-2mm-3mm-5083-5086-a5052-h32-h111-aluminium-sheets.html