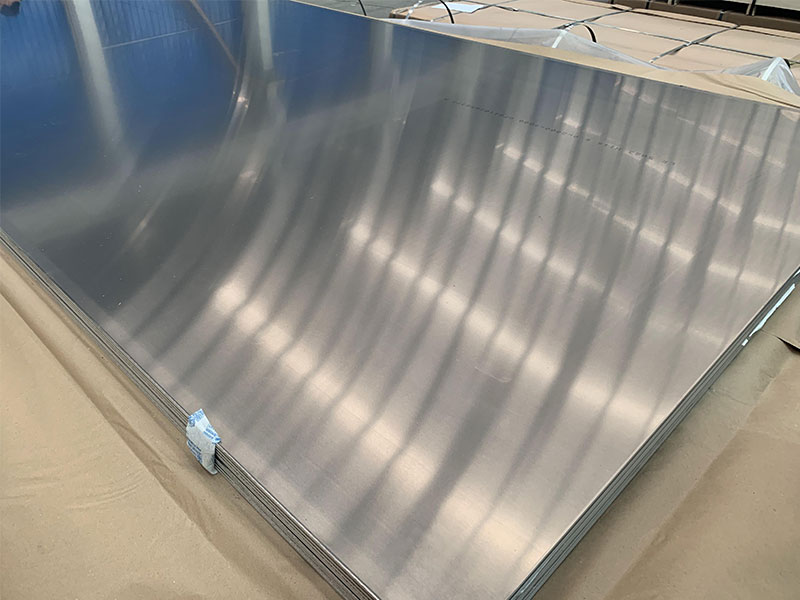

5052 temper H112 H114 H321 H34 aluminium sheets for boat construction

When it comes to building boats, selecting the right materials is crucial for safety, durability, and performance. One excellent choice is the 5052 aluminum alloy, particularly in its various temper forms—H112, H114, H321, and H34.

Understanding Aluminum Alloy 5052

The 5052 alloy belongs to the aluminum-magnesium family and is known for its impressive resistance to corrosion, strong weldability, and good formability. These traits make it especially popular in maritime applications, where saltwater environments pose a frequent challenge to structural integrity. The addition of magnesium enhances the strength and workability of the aluminum alloy, making 5052 an excellent choice for construction processes requiring both simplicity and robust performance.

Temper H112

Temper H112 signifies a strain-hardened, low-strength aluminum sheet. This form undergoes a softening process, allowing it to exhibit enhanced ductility while maintaining decent strength. When utilized in boat construction, H112 sheets are often employed for less critical structural components where weight reduction is essential and high strength is not the primary need. Due to their good corrosion resistance, H112 sheets help extend the lifespan of various boat elements, especially in non-stressed applications.

Temper H114

Similar to H112, H114 is another significant temper of the 5052 alloy, categorized as a "strain-hardened" status. However, H114 sheets exhibit higher resistance to corrosion and are therefore highly suitable for marine environments. These sheets are commonly used in boat construction for components frequently exposed to water and other corrosive elements. They are viable choices for hulls, fittings, and storage compartments where structural performance and marine resilience must work hand-in-hand.

Temper H321

The temper H321 is known for its exceptional strength and durable behavior in a secondary application context. This condition signifies a long-term anneal that provides significant benefits in resisting stress and maintaining integrity under load. H321 aluminum sheets are installed in areas requiring enhanced performance due to exposure to forces during boat operation. For boat builders prioritizing strength, H321 serves as an outstanding alternative, rising to the demands of strong and reliable boat construction while delivering optimal performance along complex stress points.

Temper H34

H34 temper is well-suited for components requiring high strength without the high temper struggles discussed with H112 and H114. This temper is achieved through minor work hardening and solidifying, which generates a robust and resilient material ideal for boat frames, decks, and structural reinforcements. The superior stiffness offered by H34 helps in controlling sagging and wavering lines in truly robust boats encountering harsh conditions, proving it indispensable for challenging boat construction requirements.

Practical Applications in Boat Construction

In practical application, selecting among 5052 H112, H114, H321, or H34 specifications allows boat builders to tailor materials for performance and structural integrity. Using a combination of these tempers in modular designs not only enhances strength but aids the ship's longevity and hydrodynamic efficiency.

-

H112 Sheet: Tailored for lightweight structures, utilized in boat panels and aesthetic components.

-

H114 Sheet: Essential for areas frequently exposed to corrosion, effectively designed for transoms and decks.

-

H321 Sheet: Recommended for load-bearing features enduring stress, ideal for reinforcing frames and hull combinations.

-

H34 Sheet: Key in creating perfectly stiff structures, fitting for overall bodily support under strenuous contractions and conditions.