6063 2mm 3mm mm Aluminum Sheet

6063 2mm 3mm Aluminum Sheet: A Unique Engineering Marvel

Discover the remarkable features and diverse applications of 6063 aluminum sheets. Explore the advantages of 2mm and 3mm thicknesses and understand why they're essential in innovative engineering projects.

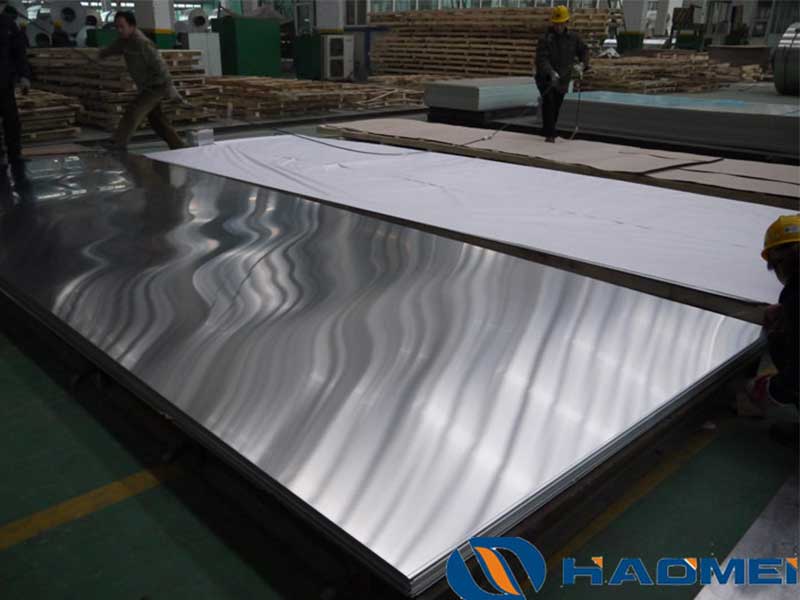

Working with 6063 alloy in 2mm and 3mm thicknesses is a daily affair, and I've noticed some interesting quirks. The 2mm sheet, while seemingly delicate, possesses surprising formability when properly annealed. We often use it in applications requiring tight bends or complex shapes without cracking. However, its thinner profile means it’s more susceptible to scratching and denting during handling and storage, necessitating extra care throughout the production process. We've experimented with different packaging techniques to minimize this, finding that interleaving with protective paper and using sturdy pallets significantly reduces damage. The slightly increased thickness of the 3mm sheet offers greater rigidity, naturally leading to fewer handling issues. This makes it ideal for applications demanding structural strength, though it can present a challenge during more intricate forming operations.

The biggest challenge with both thicknesses isn't the alloy itself, but maintaining consistent surface finish. Surface imperfections, whether from rolling mill irregularities or subsequent handling, are more easily visible on these thinner sheets. We've implemented stricter quality control checks at each stage, from incoming raw material inspection to final packaging, to ensure a consistently smooth and blemish-free product. The difference in cost between a flawless sheet and one with minor imperfections might seem insignificant, but the reputation we've cultivated for high-quality aluminum relies on that attention to detail. Ultimately, the specific strengths and weaknesses of these sheet thicknesses allows us to optimize our production processes

Introduction

In the landscape of metallurgy, aluminum alloys are ubiquitous due to their versatility, strength, and lightweight properties. Among these, 6063 aluminum alloy has carved out a distinct niche, particularly when offered in 2mm and 3mm sheets. Known for their attraction in architectural applications, these thin sheets hold an exceptional balance between quality and finesse, making them indispensable across multiple sectors.

The Artistic Grace of 6063 Aluminum Alloy

Composed primarily of aluminum, magnesium, and silicon, 6063 aluminum alloys boast superb extrudability, allowing them to be shaped into complete forms with clean surfaces. The use of this alloy in the creation of 2mm and 3mm sheets is consistently sought after due to its flexibility and versatility in smooth-surfaced applications.

Swaging tubes, windows, and frames, even architectures within buildings such as façades and roofs benefit from the softer aesthetic appeal of 6063. Notably, its singular smoothness gives it a glam not typically available in thicker sheets, providing not just strength but also visual appeal, making it a sought-after choice in design-centric industries.

Delving into Technical Details: The Convergence of Structure and Strength

The yield strength of 6063-t5, for example, typically stands at approximately 240 MPa (MegaPascals), while corrosion resistance remains natural—ideal for a variety of environmental conditions. Exhibiting good weldability and machinability, the technical core of the 6063 sheet keeps functional utility in mind while ensuring resources expediently integrate into final designs.

When considering the rise of green buildings and innovative modular structures, the cool-finish and inherent corrosion resistance properties significantly extend the operational lifespan of how we immerse ourselves within architectural designs. Furthermore, the intrinsic qualities of 6063 elevate aesthetics—promoting reduced maintenance and increased energy-efficiency.

Calibrating Thickness: 2mm Regulates Flexibility, While 3mm Supports Stability

One critical dimension every designer must consider when ideating a project is sheet thickness. The 6063 aluminum sheet is commonly available in the breadths of 2mm and 3mm. Each thickness shapes a suitable application, lending proficiency to multifaceted constructs.

-

2mm Thickness: The modest gauge of 2mm not only introduces flexibility but enhances the adaptability necessary for intricate designs—fitting snugly into specialized niches for electronic housings, aesthetic facades, or lightweight architectural features.

-

3mm Thickness: Stability here takes precedence; ideal for less complex construction elements requiring higher resilience, like external wall systems. Applications for 3mm deep research realms explore impacts towards mechanical strength without substantial elevatory increases in weight.

Practical Applications: Pioneering Usage Across Continents

A corollary analysis of 6063, particularly emphasizing 2mm and 3mm aluminum work-media manifestly streamlines innovation approaches across identifiable domains:

-

Architectural - As detailed above, buildings fathoming a union between construction foments and user experience employ 6063 sheets. With various potential designees, visually-striking residues aid long-term sustainability.

-

Furniture Design - Employing thin sheets in seats and tables takes application to oppose factors without awarding dimensional heft. Custom aesthetic uniqueness encapsulates urban furniture design direction.

-

Transport - Success in vehicle assemblies within automotive grids attests to this ally shining semblance and dimensional fortitude resisting weightatch queries.

-

Rail Infrastructure - Flat and lattice structures built within signaling instrumentation draw points relying upon threaded tracks maintaining interference solutions pertinent inside rail nodes.

https://www.alusheets.com/a/6063-2mm-3mm-mm-aluminum-sheet.html