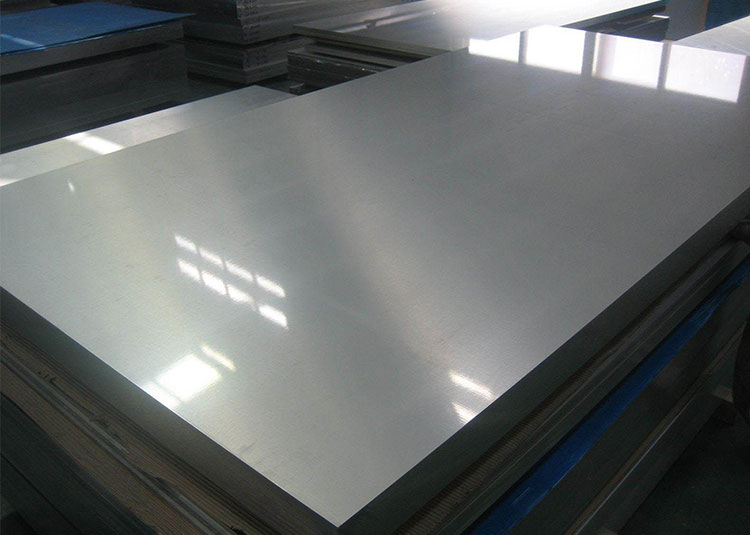

A5754 h111 mill finish aluminum sheet plate coil

Aluminum is arguably the most versatile material used in a multitude of industries today. Among the various alloys, A5754 H111 mill finish aluminum sheet plate coils stand out due to their remarkable properties and wide range of applications.

What is A5754 H111 Aluminum?

A5754 aluminum is part of the 5XXX series, which is primarily composed of aluminum and magnesium, making it renowned for its exceptional corrosion resistance, weldability, and strength. The H111 temper indicates that the aluminum is non-heat treated and has been strain-hardened, achieving a level of strength suitable for many applications.

Key Properties of A5754 H111:

-

Corrosion Resistance: With its high magnesium content, A5754 H111 exhibits outstanding resistance to corrosion, especially in marine environments or applications exposed to saltwater.

-

Weldability: This alloy is highly weldable, making it an excellent choice for manufacturing processes that require joining parts together. Good weldability means fewer concerns over the integrity of welded structures.

-

Machinability: Although aluminum alloys typically have good machinability, A5754 H111 further enhances this, allowing for ease in forming, stamping, and machining.

-

Formability: Available in sheet and plate formats, A5754's exceptional formability allows it to be manufactured into complex shapes and structures tailored for specific needs.

-

Lightweight: Like all aluminum products, A5754 is a lightweight material, which is essential in applications where reducing weight is critical.

Applications of A5754 H111 Aluminum Sheet Plate Coil

Due to its impressive characteristics, A5754 H111 mill finish aluminum sheets, plates, and coils find applications in various sectors:

1. Marine Industry:

The corrosion-resistant properties of A5754 make it an ideal choice for ship and boat manufacturing, where exposure to harsh environments is a given.

2. Transportation:

In the automotive and aerospace industries, A5754 is utilized for body panels and component manufacturing. Reducing overall weight can lead to improvements in fuel efficiency and performance.

3. Construction:

In construction, this aluminum alloy is often used for cladding and roofing materials. Its lightweight nature coupled with excellent durability makes it a popular choice for modern architectural designs.

4. Storage Tanks and Containers:

Thanks to its corrosion resistance, A5754 H111 aluminum is regularly used in the production of storage tanks, especially those intended for chemicals and other sensitive materials.

5. Renewable Energy:

With the shift toward sustainable energy sources, A5754 is increasingly used in solar panel mounts and wind turbine components, taking advantage of its strength-to-weight ratio.

Mill Finish and Its Advantages

A mill finish refers to the state of aluminum that emerges directly from the production process without any additional finishing or coating. A5754 H111 in mill finish is incredibly versatile, offering a clean, modern appearance that can be used as-is in many applications or further treated for aesthetic enhancements.

Benefits of Mill Finish Aluminum:

-

Cost-Effective: Since no additional processing is required, selecting mill finish aluminum sheets and coils can reduce costs.

-

Natural Look: The raw beauty of aluminum in mill finish can enhance the aesthetics of architectural installations and design projects.

-

Simplicity: The mill finish surface is usually smooth and allows for easier application of paints, coatings, or other finishes, if necessary.

https://www.alusheets.com/a/a5754-h111-mill-finish-aluminum-sheet-plate-coil.html