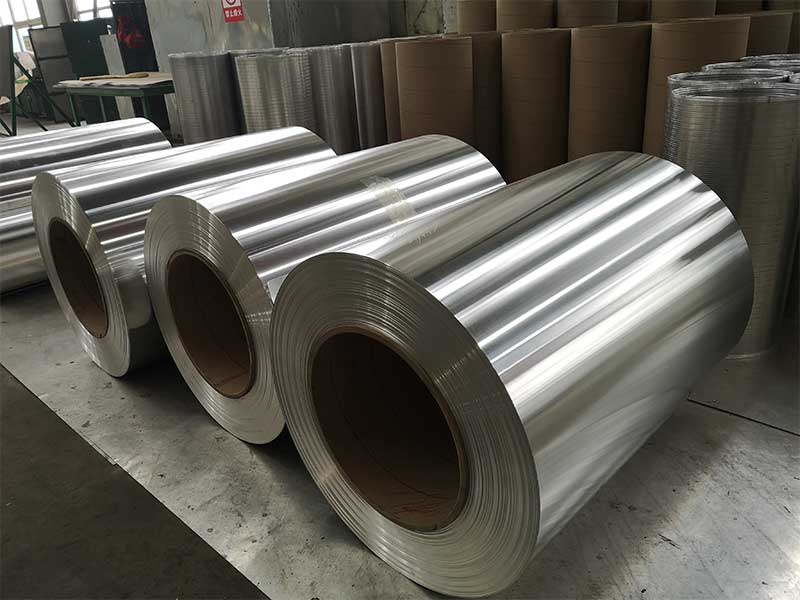

Aluminum coil 3004, 3105, 5052, 5083, 5182, 5754

Aluminum coils are a staple in modern manufacturing, providing lightweight, high-strength materials ideal for a plethora of applications. Among the myriad of aluminum alloy grades, 3004, 3105, 5052, 5083, 5182, and 5754 stand out due to their unique properties and versatility.

Aluminum Coil 3004

Aluminum coil 3004 belongs to the 3000 series, which is well-known for its superior corrosion resistance and formability. Composed primarily of aluminum with manganese as its principal alloying element, this grade typically contains 1-1.5% manganese and exhibits excellent mechanical properties. It’s commonly found in can bodies and beverage packaging, where lightweight materials contribute to improved energy efficiency and lower transportation costs.

Applications: Food and beverage cans, pressure vessels, and roofing.

Aluminum Coil 3105

Another member of the 3000 series, aluminum coil 3105 is particularly noted for its superior weather resistance and finish retention, making it an ideal choice for exterior applications. It primarily contains manganese but is alloyed with small amounts of copper, adding to its overall strength and durability. Its excellent formability allows it to be fabricated into different shapes without compromising performance.

Applications: Residential siding, mobile homes, rain-carrying goods, and fuel tanks.

Aluminum Coil 5052

Part of the 5000 series, aluminum coil 5052 is notable for its impressive strength and resistance to corrosion, particularly in marine environments. This alloy contains magnesium as its main alloying element, boasting high fatigue strength and weldability. As such, 5052 coils are frequently utilized in applications that require both durability and lightweight considerations.

Applications: Marine structures, automotive fuel tanks, pressure vessels, and meal trays.

Aluminum Coil 5083

Aluminum coil 5083 is another powerful member of the 5000 alloy series, famous for its exceptional performance under harsh conditions. This alloy encompasses magnesium and traces of manganese and chromium, resulting in a robust product with notable fatigue strength and excellent corrosion resistance. Its ability to withstand demanding environments makes this coil grade ideal for marine applications.

Applications: Shipbuilding, pressure vessels, and vehicles exposed to harsh operational conditions.

Aluminum Coil 5182

Aluminum coil 5182 shares similarities with the 5083 alloy but is designed primarily for applications in the automotive industry. It boasts a combination of magnesium, manganese, and iron, leading to excellent capacity for deformation while maintaining strength. The cost-effectiveness and manufacturability of this alloy make it a popular choice for producing high-quality, lightweight automotive components.

Applications: Automotive parts, such as body structures and flooring.

Aluminum Coil 5754

Aluminum coil 5754 provides a perfect combination of strength and lightweight features, marking it as one of the most versatile members of the 5000 series. Featuring magnesium as its primary alloying element, 5754 has excellent resistance to seawater and other corrosive environments, making it optimal for maritime applications.

Applications: Shipbuilding, automotive components, and structural applications.

https://www.alusheets.com/a/aluminum-coil-3004-3105-5052-5083-5182-5754.html