Lithium ion battery aluminum foil

The demand for efficient and lightweight energy storage has skyrocketed as a result of the rapid growth in portable electronics, electric vehicles, and renewable energy solutions. At the heart of lithium-ion batteries—a preferred choice for these applications—lies one vital component: aluminum foil.

The Role of Aluminum Foil in Lithium-Ion Batteries

Lithium-ion batteries hold an extensive market share primarily due to their superior energy density and long cycle life. Within each battery are electrodes made up of specific materials that influence overall performance. Aluminum foil is primarily utilized as the current collector for the positive electrode or cathode.

Why Aluminum Foil?

-

Conductivity & Efficiency: Aluminum possesses excellent electrical conductivity, allowing for efficient electron transfer during battery operation. This plays a crucial role in maximizing the current output of a lithium-ion cell, resulting in a more efficient energy delivery system.

-

Lightweight Properties: The lightweight nature of aluminum contributes to the reduced overall weight of the battery. This characteristic is vital for applications in electric vehicles and consumer electronics, where minimizing weight contributes to increased efficiency and mobility.

-

Corrosion Resistance: Lithium-ion batteries operate under various environmental conditions, and the stability of their components is imperative. Aluminum foil showcases impressive corrosion resistance, ensuring the longevity of the cathode and the overall battery life.

-

Cost-Effectiveness: Compared to other materials that could serve similar functions, aluminum is relatively inexpensive, making it a popular choice in manufacturing processes for large-scale battery production.

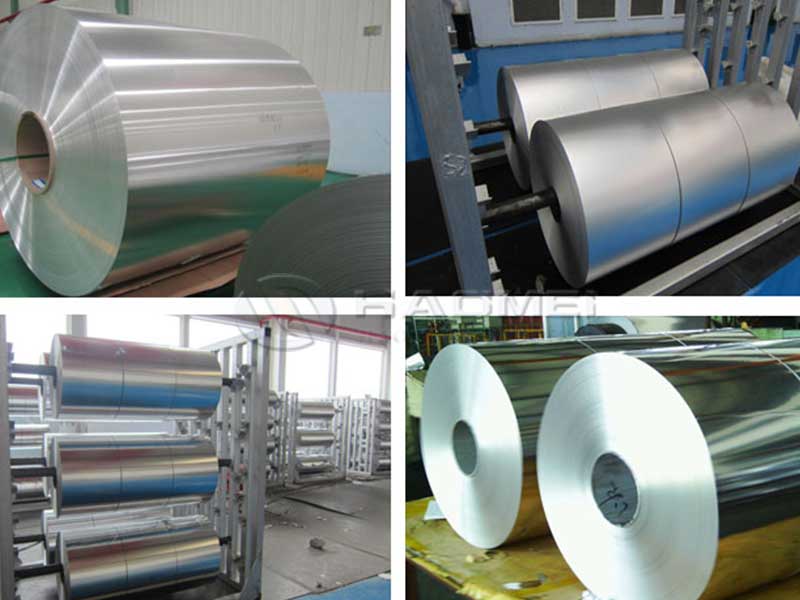

Manufacturing Process of Aluminum Foil for Lithium-Ion Batteries

The production of aluminum foil suitable for use in lithium-ion batteries involves several critical steps:

-

Aluminum Ingots Preparation: The foam begins as purified aluminum ingots, which are responsive to differing fabrication processes.

-

Rolling: The ingots are altered through a series of cold rolling, where they are compressed to create thin aluminum foil—a required thickness provides the ultimate balance for flexibility and performance.

-

Cleaning & Surface Treatment: After rolling, the foil is cleaned to remove any contaminants that could affect its performance and undergoes treatments to enhance its surface characteristics, including chemical treatments that improve adherence with electrode materials.

-

Slitting: The final rolled sheets are cut into specified widths, essential for attachment to battery assembly machines.

Sustainable Practices in Aluminum Foil Production

As society pushes towards more sustainable solutions, advancements within aluminum foil production for lithium-ion batteries are of paramount importance. The recycling potential of aluminum—a readily recyclable material—shows that much of the new aluminum foil is derived from recycled materials sourced from post-consumer products. This not only minimizes waste but also drastically reduces energy consumption in new products' manufacturing.

Additionally, innovations in production technologies seek to lower the overall carbon footprint further, making aluminum foil an environmentally friendly option compared to other current collector materials.

https://www.alusheets.com/a/lithium-ion-battery-aluminum-foil.html