The difference between hot rolled aluminum sheet dc and continuous casting rolling aluminum sheet cc

Aluminum is one of the most versatile metals used in a variety of industries, owing to its excellent properties such as lightweight, strength, and corrosion resistance. When it comes to manufacturing aluminum sheets, two prominent methods stand out: hot rolling (DC – Direct Casting) and continuous casting rolling (CC). Each technique has its unique characteristics, advantages, and applications.

What is Hot Rolled Aluminum Sheet DC?

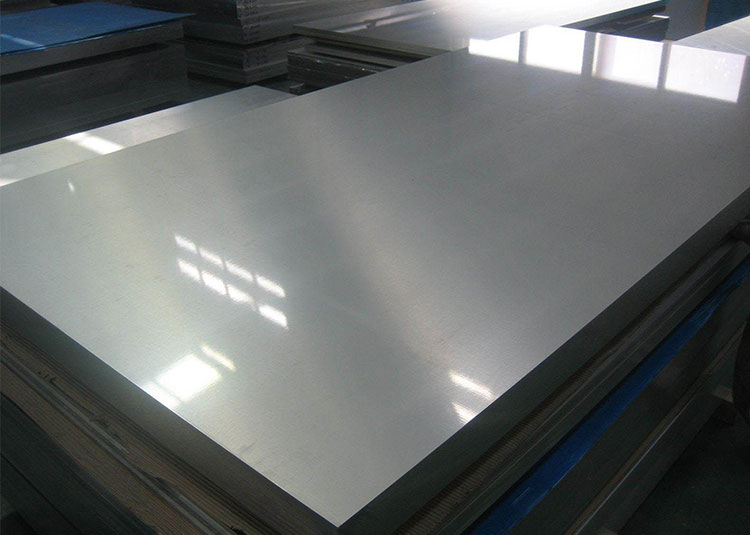

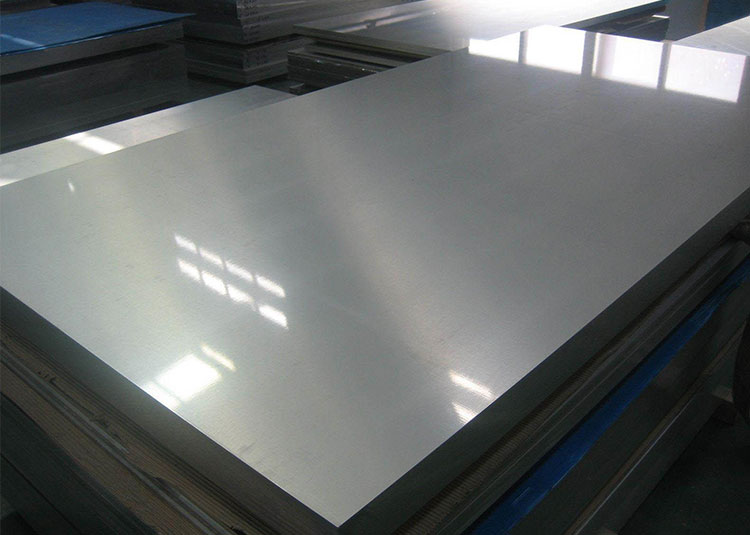

Hot rolled aluminum sheets, produced through the direct casting (DC) method, undergo a heating process where aluminum ingots are heated above their recrystallization temperature and then rolled into sheets. This method results in larger sheets with exceptional mechanical properties, allowing for significant deformation without compromising strength.

Characteristics of Hot Rolled Aluminum Sheet DC:

- Grain Structure: The heating process changes the grain structure of the aluminum, enhancing its ductility.

- Surface Finish: Typically, hot rolled sheets may have a rougher surface finish compared to cold rolled sheets.

- Thickness Variability: The hot rolling process allows for a wider range of thicknesses, accommodating various applications from structural components to decorative features.

- Strength and Hardness: Sheets produced through this method generally exhibit good strength and can be hardened through various heat treatment techniques.

Applications:

Hot rolled aluminum sheets (DC) find extensive application in high-stress environments such as aerospace components, marine applications, and automotive manufacturing, where mechanical strength and durability are paramount.

What is Continuous Casting Rolling Aluminum Sheet CC?

Continuous casting rolling (CC) is another manufacturing technique that produces aluminum sheets, although the process differs significantly from the DC method. In the CC process, molten aluminum is continuously poured into a mold, where it solidifies and is then rolled into a sheet before cooling. This method typically creates sheets with a finer and more uniform grain structure.

Characteristics of Continuous Casting Rolling Aluminum Sheet CC:

- Uniform Thickness and Width: Continuous casting allows for more consistent dimensions in width and thickness, enabling precision fabrication.

- Surface Quality: CC sheets tend to have superior surface quality and finish compared to hot rolled sheets.

- Lower Internal Stresses: The rapid cooling process during casting minimizes internal stresses, leading to better machinability.

- Thermally Stable: CC produced sheets exhibit better thermal stability, making them suitable for applications where temperature fluctuations occur.

Applications:

Continuous casting rolling aluminum sheets (CC) are often used in applications requiring precise specifications, such as electrical conduits, architectural features, and components for food processing equipment due to their clean finish and stability.

Key Differences at a Glance

| Feature | Hot Rolled Aluminum Sheet (DC) | Continuous Casting Rolling Aluminum Sheet (CC) | |