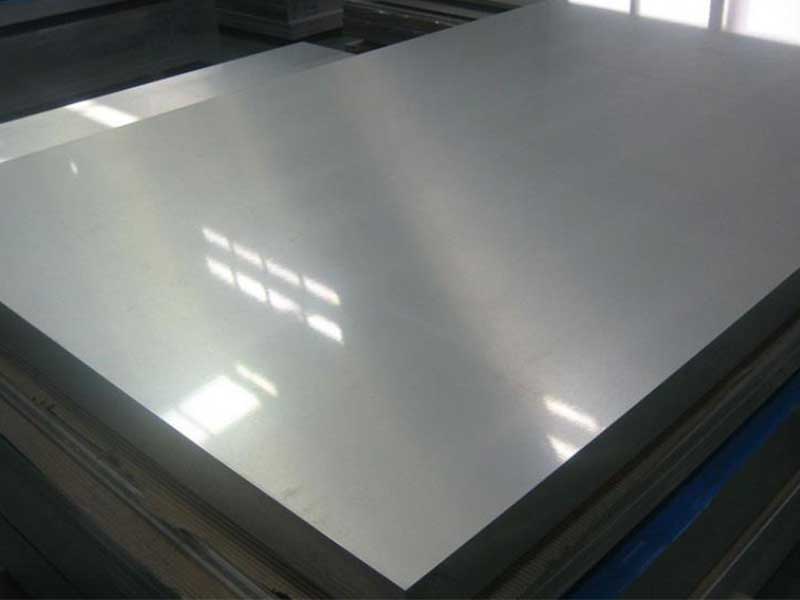

Aluminium Sheet 1100 1050 H14 Mill

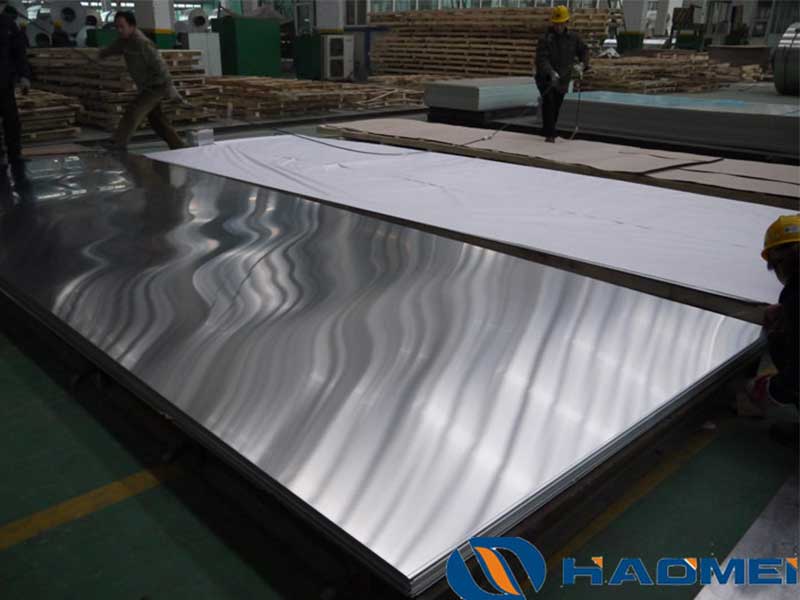

Aluminum sheets are widely used in various industries due to their unique combination of characteristics, making them crucial materials for numerous applications. Among the different grades available, Aluminum Sheet 1100 and 1050 H14 Mill are noteworthy for their specific attributes and versatility.

Overview of Aluminum Sheet Grades

Aluminum is available in various series based on its alloying elements, with each series offering distinct properties and advantages. The 1000 series, which includes both 1100 and 1050 aluminum sheets, is primarily composed of 99% or higher aluminum content. This high purity contributes to their excellent corrosion resistance, enhanced electrical conductivity, and flexibility.

Properties of Aluminum Sheet 1100 1050 H14 Mill

- Chemical Composition:

- 1100 Series: The 1100 aluminum alloy contains 99% aluminum and is primarily chosen for its combination of high corrosion resistance and excellent workability.

- 1050 Series: Similar to the 1100 alloy but refined further for different gradual or strength demands, typically featuring slightly improved mechanical properties.

- Temper H14:

- The H14 designation indicates an aluminum sheet that has been strain-hardened to half of its maximum strength potential, significantly enhancing its mechanical performance. This temper provides moderate gauge robustness while retaining ductility, making it suitable for forming operations.

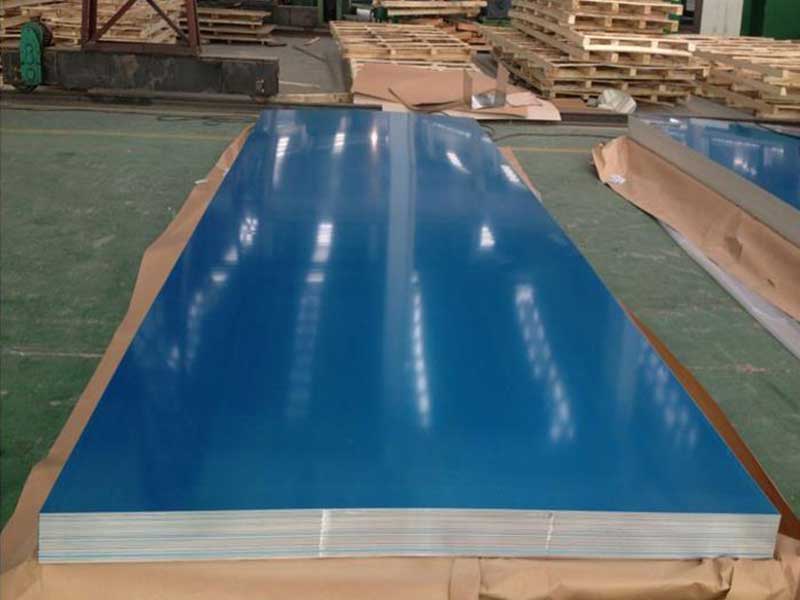

- Thickness and Form Factors:

- Availability in various thicknesses and capable of further fabrication and bending processes. This versatility makes Aluminum Sheet 1100 1050 H14 Mill a top choice for engineering applications.

- Thermal Conductivity:

- The high metallic content results in exceptional thermal conductivity. This characteristic makes these sheets ideal for applications requiring efficient heat dissipation and temperature control.

- Weight to Strength Ratio:

- One of the standout features of aluminum sheets in this category is their remarkable weight-to-strength ratio, allowing for lightweight designs without compromising on strength.

Common Applications of Aluminum Sheet 1100 1050 H14 Mill

Aluminum Sheet 1100 1050 H14 Mill is widely employed across various industries due to its desirable properties:

-

Air Conditioning and Refrigeration: The superior thermal conductivity of the metal type is ideal for creating efficient cooling systems.

-

Food and Chemical Industries: The corrosion-resistant properties make these sheets great for applications involving food storage, handling, processing machinery, and chemical tanks.

-

Decorative Applications: Calm and Road Sign manufacturing take advantage of the aesthetic versatility of Aluminum Sheets, with anodizing procedures enhancing their visual appeal.

-

Transportation Manufacturing: Lightweight structural components made from Aluminum Sheet H14 provide significant fuel-efficiency benefits in the production of airplanes, cars, and rail transport vehicles.

https://www.alusheets.com/a/aluminium-sheet-1100-1050-h14-mill.html