Thermal PSCTP Plate Positive PS Plate for for Offset Print

Discover the advantages of Thermal PSCTP Plates for Offset Printing. From enhanced print quality to cost efficiency, our comprehensive guide explores the crucial details and unique benefits of Positive PS Plates in the modern printing landscape.

Unveiling the Efficiency of Thermal PSCTP Plates in Offset Printing

The world of offset printing is no stranger to innovation, and one such marvel transforming print production is the Thermal Positive PS (Photosensitive) CTCP Plate. As an Aluminum Alloy Expert, it’s vital to dive deep into these plates, unveiling their unique aspects and performance benefits in today’s print market.

The thermal positive PS CTP plate, specifically for aluminum substrates, represents a fascinating intersection of traditional offset printing and advanced materials science. While seemingly a straightforward technology, its nuanced performance characteristics require a deeper to truly optimize its use and leverage its full potential.

1. Beyond the "Positive" Simplicity: Substrate Interaction & Latent Image Quality: The term "positive" implies a simple relationship – exposed areas become imaged, unexposed areas remain inert. However, the reality with thermal PS plates on aluminum is far more intricate. The interaction between the photosensitive layer, the aluminum substrate's alloy composition and surface treatment, and the thermal energy profile during exposure dramatically influences latent image quality. A seemingly minor variation in any of these factors – the aluminium's grain size, the anodized layer thickness, even the ambient humidity during exposure – can significantly affect the resolution, dot gain, and overall print quality. Ignoring this substrate-dependent nuance leads to inconsistent results and the incorrect assumption that all positive thermal plates perform identically. Expert users recognize the need for meticulous control and potentially even plate-substrate matching for premium output.

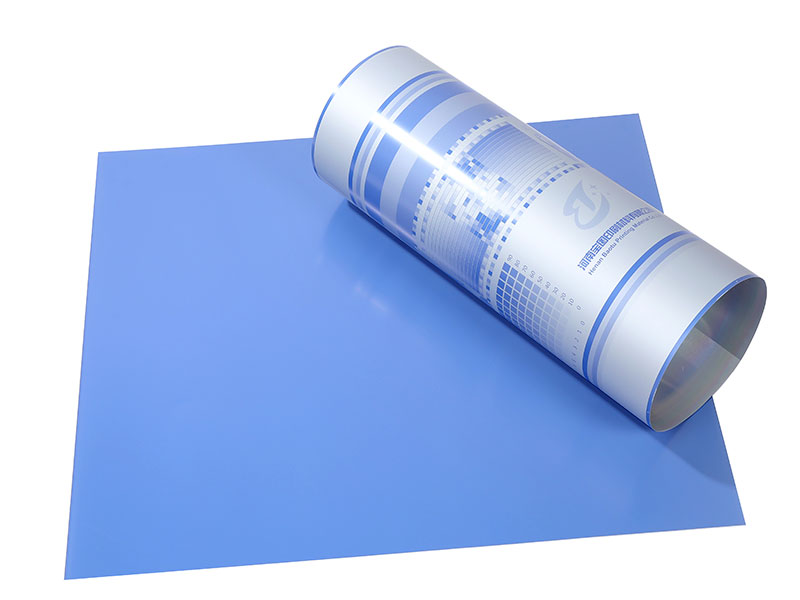

What Are Thermal Positive PSCTP Plates?

Thermal Positive PSCTP Plates are specialized plates used in the process of offset printing, formulated specifically for high-speed and high-quality print production. Comprised of a robust aluminum backing combined with a light-sensitive polymer layer, these plates bring a multitude of advantages to printers looking to upgrade their processes.

While traditional PS plates operate with similar functions, the thermal PSCTP variant elevates applications with significant technological advancements:

-

Thermal Sensitivity: Utilizing thermal activation, these plates expose and develop differently than conventional photopolymer plates. The heat source used during exposure ensures rapid processing times and operational efficiencies, drastically reducing idle times in production cycles.

-

Positive Image Development: The "positive" distinction denotes a aspect; unlike negative plates where the exposed areas are washed away post-exposure, Thermal Positive PSCTP Plates solidify the traceable areas post-illumination. Resulting in crisp and clear imagery, retaining even the most intricate details.

-

Eco-Friendly Process: Environmental considerations are paramount in today’s printing technology. Thermal processing reduces emissions and usage of harmful chemicals present in conventional plate developers, benefiting not just the planet but also aligning with stringent environmental regulations.

Advantages in Detail

-

Improved Print Quality: With Thermal Positive PS Plates, end products boast exceptional line crispness and color fidelity. Their exposure characteristics facilitate uniform imaging across diverse designs, something especially advantageous for graphic-heavy projects that demand precision.

-

Enhanced Durability: Constructed to withstand rigorous commercial printing, these plates prevent wear and thermal degradation. This durability minimizes plate wear-offs, ensuring long printing runs with fewer replacements, thus lowering production costs.

-

Faster Processing Times: Designed for a seamless workflow, these plates drastically cut down on the time between plate exposure and press preparation. With rapid development and easy handling, printers can quickly transition between jobs, enhancing overall operational efficiency.

-

Reducing Waste and Costs: The constant demand for quick turnaround times in printing services means any pauses in production to change or replate can lead to significant financial drains. The advanced technology embedded in Thermal PSCTP Plates contributes to a bottom line that reflects reduced waste—all whilst extending plate capabilities, improving long-term profitability.

Practical Applications in Offset Printing

Moving forward, numerous applications for Thermal PSCTP Plates exist across the printing industry. From newspapers and magazines requiring high-capacity printing methods to smaller press needs meant for precision tasks such as marketing materials, businesses find a reliable partner in these plates designed for longevity and efficiency.

Furthermore, with customization rolls in shifts, businesses that seek distinctive printing requirements find sub-setting CTCP formats increasingly inspiring, paving the way for cooperation between technological mastery and the art of print.

https://www.alusheets.com/a/thermal-psctp-plate-positive-ps-plate-for-for-offset-print.html