| Specifications | ||||||||

| Alloy | Temper | Thickness | Width | Length | Coil | Strip | Earing | Diagonal |

| 3105, 8011 | H14, H16, H24, H26 | 0.15~0.25 mm (+/-0.005mm) | 500~1000 mm (+0.5mm, -0mm) | 500~1000 mm (+0.5mm, -0mm) | 500~1000 mm | 20~500 mm | 1 | ≤ 1mm |

Chemical Compositions DC & CC Aluminum Closure Sheet | ||||||||||||

| Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

| Each | Total | |||||||||||

| 8011 | 0.60~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | – | 0.08 | 0.05 | 0.15 | Remain |

| 3105 | 0.7 | 0.6 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | – | 0.1 | 0.05 | 0.15 | Remain |

| Mechanical Property For Direct Casting | ||||

| Alloy | Temper | Thickness(mm) | U.T.S(Mpa) | Elongation(%) |

| 8011 | H14 | 0.15~0.25 | 125~155 | ≧2 |

| 3105 | H14 | 0.15~0.25 | 150~200 | ≧1 |

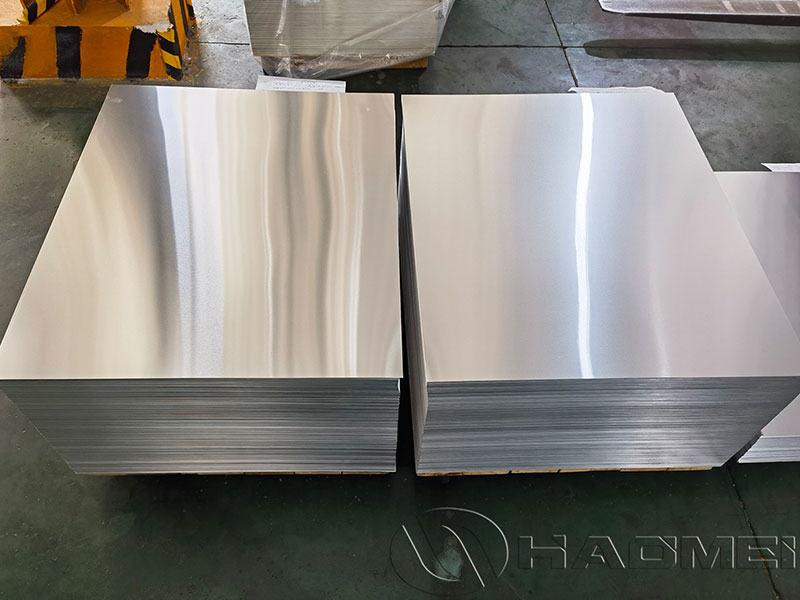

Aluminum closure sheets have become integral in various industries, thanks to their versatility, durability, and sustainability. Among these, DC (Direct Chill) and CC (Continuous Cast) aluminum closure sheets stand out as pivotal players in the packaging sector.

Understanding DC & CC Aluminum Closure Sheets

Aluminum closure sheets are thin, lightweight aluminum sheets used primarily in the packaging industry to create closures such as caps and lids. These sheets are vital in ensuring the integrity and safety of packaged goods, particularly in the food, beverage, and pharmaceutical sectors.

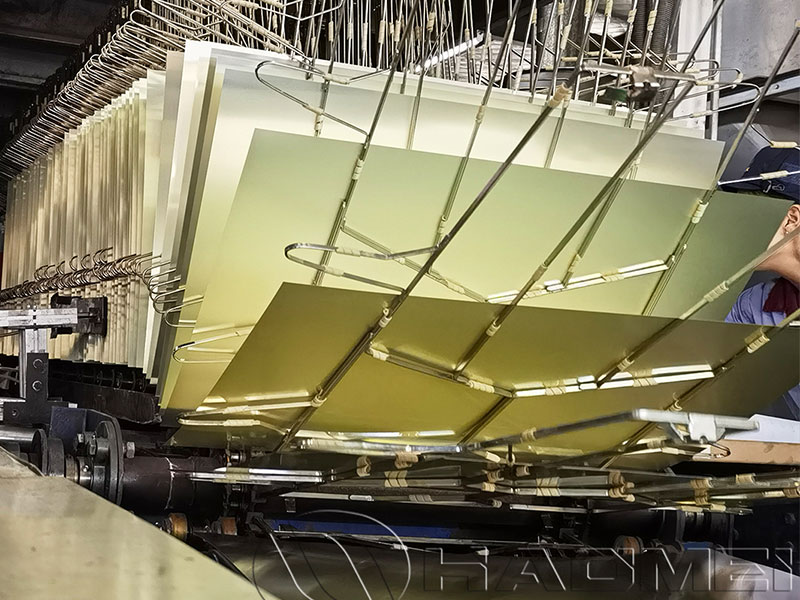

The main distinction between DC and CC aluminum closure sheets lies in their manufacturing processes:

- Direct Chill (DC) Casting: A traditional method where aluminum is cooled slowly in molds. This results in a finer grain structure, offering superior surface quality and mechanical properties.

- Continuous Casting (CC): A modern, efficient method where molten metal is cast into sheets continuously. This process is faster and more cost-effective, producing a slightly coarser grain structure but still maintaining good quality for many applications.

Benefits of DC & CC Aluminum Closure Sheets

DC Aluminum Closure Sheets

- Superior Surface Quality: The slow cooling process of DC casting results in a smoother, higher-quality surface, making it ideal for applications requiring precision and aesthetic appeal.

- Excellent Mechanical Properties: DC sheets have superior strength and formability, making them suitable for applications where durability is paramount.

- Versatility: These sheets can undergo extensive forming and machining, accommodating complex designs and closures.

CC Aluminum Closure Sheets

Cost-Effective: The continuous casting process is less labor-intensive and consumes less energy, leading to lower production costs.

Efficient Production: Continuous casting allows for faster production speeds, making CC sheets ideal for high-volume manufacturing.

- Adaptability: While slightly coarser than DC sheets, CC sheets still offer sufficient quality for a wide range of closure applications, particularly in cost-sensitive industries.

Applications of DC & CC Aluminum Closure Sheets

Both DC and CC aluminum closure sheets are used across various sectors due to their adaptability and reliable performance:

- Beverage Industry: Aluminum closures are essential for sealing bottles and cans, preventing leaks, and maintaining the freshness of carbonated drinks, juices, and wines.

- Pharmaceuticals: Aluminum closures provide a non-reactive, sterile seal for medical containers, ensuring product safety and integrity.

- Food Packaging: They offer an effective barrier against moisture, oxygen, and contamination, thus extending the shelf life of food products.

- Cosmetics & Personal Care: Lightweight and resistant to corrosion, aluminum closures provide a sleek, stylish finish to packaging while ensuring product safety.

Sustainability and Environmental Impact

One of the most compelling benefits of aluminum closure sheets is their environmental sustainability. Aluminum is infinitely recyclable without losing its properties, reducing the demand for new raw materials and minimizing the carbon footprint. Both DC and CC processes contribute to a more sustainable packaging industry by supporting the production of recyclable aluminum closures.