10-25 Micron Embossed Aluminum

Introduction

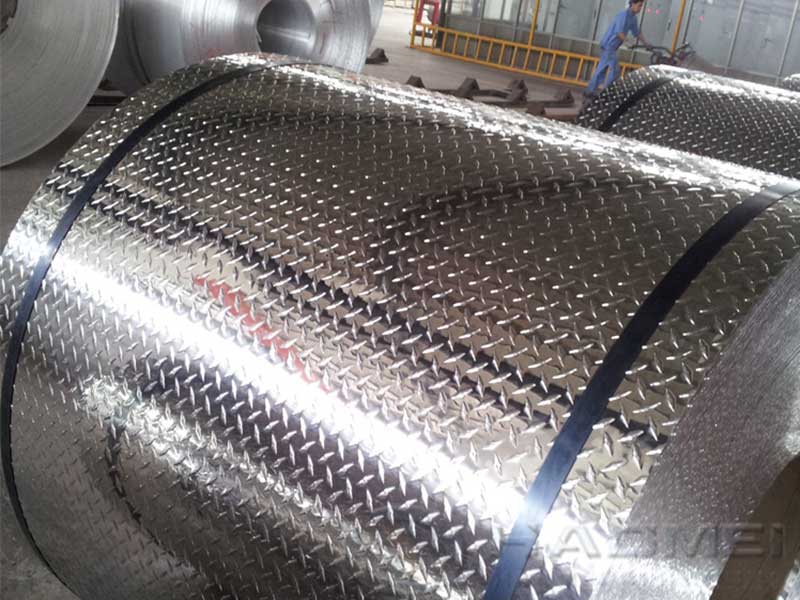

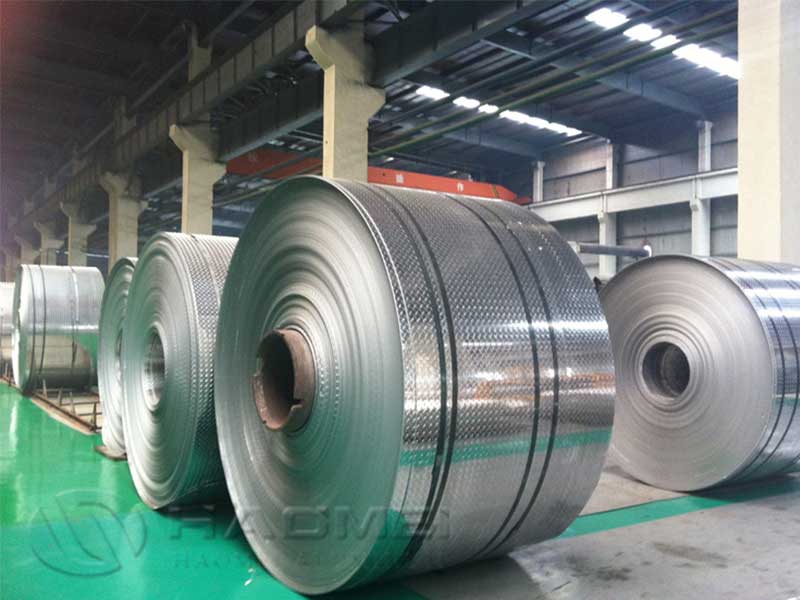

Embossed aluminum has garnered substantial interest across numerous industries due to its unique properties and aesthetic appeal. Specifically, aluminum sheets that fall within the 10-25 micron thickness range offer an outstanding combination of durability, lightweight composition, and versatility.

Features of 10-25 Micron Embossed Aluminum

-

Lightweight Yet Durable: The 10-25 micron thickness makes this embossed aluminum exceptionally lightweight, enabling easier handling and installation. Despite its reduced weight, this material maintains high levels of durability and strength, making it a reliable choice for various applications.

-

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, especially in embossed finishes. This layer offers excellent resistance against corrosion, extending the lifespan of embossed aluminum in outdoor and harsh environments.

-

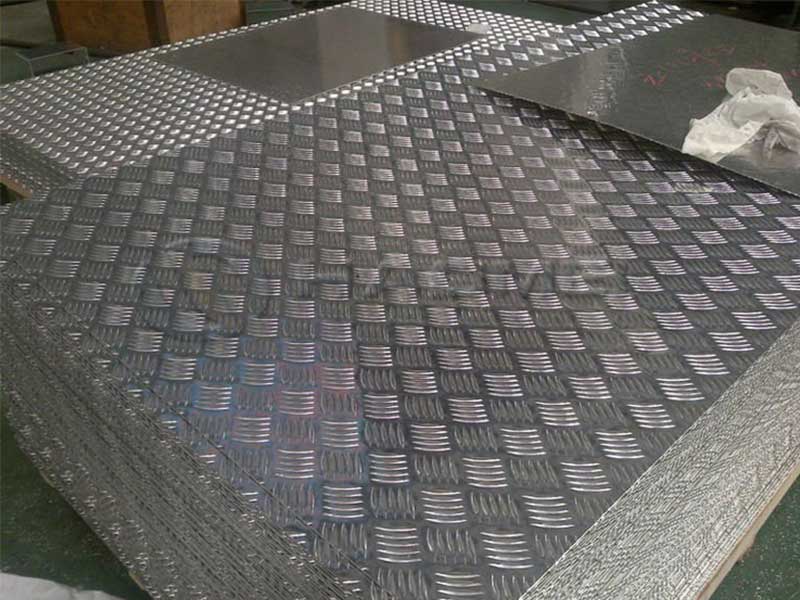

Aesthetic Appeal: The embossed finish not only enhances the material's visual aesthetics but also improves its slip resistance. With various patterns available, it can be chosen to match specific design themes, making it ideal for decorative applications.

-

Thermal Conductivity: Aluminum is well-known for its high thermal conductivity properties, promoting efficient heat transfer in applications where heat management is essential. This characteristic is particularly beneficial in industries like refrigeration and HVAC systems.

-

Sound Insulation: The surface pattern of embossed aluminum can aid in sound proofing applications, helping to absorb sound and reduce noise pollution within enclosed spaces.

Applications of 10-25 Micron Embossed Aluminum

-

Packaging Solutions: The food and beverage packaging industry frequently utilizes 10-25 micron embossed aluminum for creating attractive, lightweight packaging that also boasts excellent barrier properties. Its durability ensures that products remain protected during transportation.

-

Architectural Applications: In architecture, embossed aluminum serves as an eye-catching design element. Commonly used for facades, ceilings, and wall cladding, this material meets both practical and aesthetic needs by safeguarding buildings from environmental wear while providing a stylish look.

-

Automotive Industry: The automotive sector employs embossed aluminum in components such as interior trims and under-hood applications, taking advantage of its lightweight property to improve fuel efficiency without sacrificing durability.

-

Consumer Goods: Many consumer products incorporate 10-25 micron embossed aluminum for items like electronics casings and decorative containers. The unique design elevates the product's appearance while also being functional.

-

Residential & Commercial Interiors: Embracing embossed aluminum in interior design, homeowners and business owners adopt these sheets for feature walls, decorative accents, and artistic installations due to their modern appeal.

Conclusion

The combination of lightweight, durable, and aesthetically pleasing qualities makes 10-25 micron embossed aluminum a highly sought-after material across diverse industries. Its practical applications from food packaging to architectural design showcase the material's versatility and breadth of possibilities. Whether you are looking to enhance a product’s appeal or seeking an effective solution for construction, this innovative material continues to prove itself invaluable. Embrace the unique benefits that 10-25 micron embossed aluminum offers in your next project.

https://www.alusheets.com/a/10-25-micron-embossed-aluminum.html