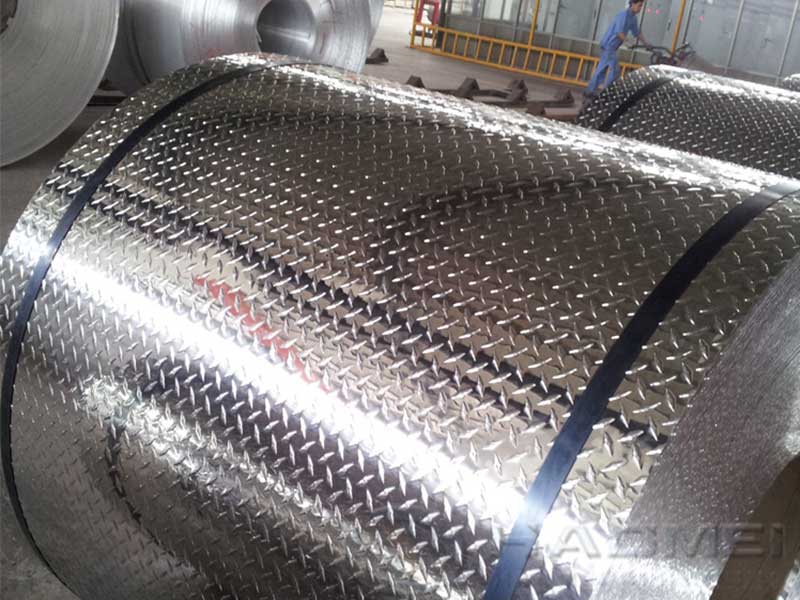

Aluminium Pattern Embossed Aluminum Coil 1100 1060 3003

Aluminium pattern embossed coils are a vital material in numerous industries, known for their ergonomic features and aesthetic designs. The aluminum grades 1100, 1060, and 3003 are prominent for their unique properties and applications across diversified markets.

Features of Aluminium Pattern Embossed Coils

1. Corrosion Resistance

Aluminum is naturally resistant to corrosion, making it particularly useful for environments that need durable products. The embossed pattern also aids in preventing wear and tear, enhancing the product's overall lifespan.

2. Lightweight yet Durable

Aluminum coils are lightweight, which makes them easier to handle and transport. The grade 1100 is especially popular for its excellent malleability, while 3003 is known for tensile strength, which can amplify structural integrity where needed.

3. Aesthetic Appeal

One of the most notable features of aluminum pattern embossed coils is their aesthetic texture. The patterns can add visual interest, making them suitable for decorative purposes as well as practical applications. Different embossing patterns, such as diamond, stucco, or custom options, provide variations that can cater to specific design preferences.

4. Versatility in Fabrication

Aluminium coils are very adaptable in fabrication processes. They can be easily processed through forming, cutting, and machining. The 1060 alloy, being highly conductive and corrosion-resistant, is often employed in situations where high purity and a broad finishing versatility are necessary.

5. Non-slip Surface

The embossed patterns create a non-slip surface, making these products beneficial in various safety applications. This characteristic is highly valued in flooring, transportation, and as cladding material in buildings.

Applications of Aluminium Pattern Embossed Coils

1. Construction Industry

Pattern embossed aluminum coils are frequently found in building applications, particularly in facades, ceilings, and wall panels. Their low maintenance and corrosion-resistant properties make them popular choices for exteriors, enhancing both function and form.

2. Transportation

In the automotive and marine industries, aluminum embossed sheets are utilized for a variety of components, including flooring and decorative finishes. The non-slip and lightweight nature of these substrates adds to the safety and efficiency of vehicles.

3. Manufacturing

Various manufacturing sectors apply aluminum pattern embossed coils for products that require high durability combined with aesthetic value. This includes items such as refrigerator liners, interior sporting goods, and various finished appliance tubing.

4. Food Processing and Packaging

Due to being easily cleaned and resistant to corrosion, aluminum coils are commonly recognized within food processing and packaging. The 1100 and 3003 grades characterize the dental integrity of foodgrade materials, ensuring safety and hygiene up to consumption standards.

5. Signage and Accessories

The distinctive appearance of embossed aluminum coils makes them highly desirable for signage, displays, and retro-style accessories. The lightweight feature allows for easy installation, and the durability secures long-lasting use in various conditions.

https://www.alusheets.com/a/aluminium-pattern-embossed-aluminum-coil-1100-1060-3003.html