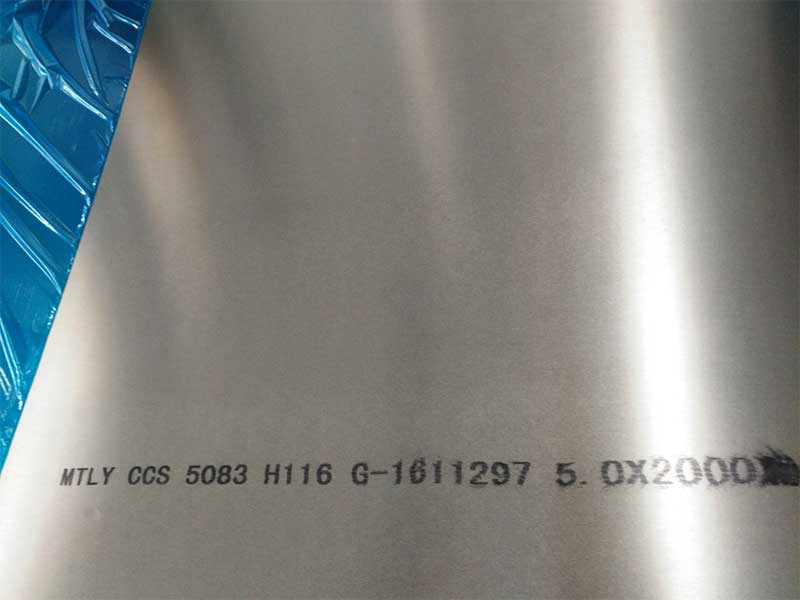

5083 h116 h321 3mm 5mm 10mm thickness marine aluminum sheet plate

The maritime industry demands materials that can withstand challenging environments while delivering superior performance. Aluminum alloys—particularly 5083 H116 and H321—have emerged as foundational materials, offering versatility and strength for vessels and marine structures.

5083 Aluminum Alloys

5083 aluminum plate falls under the category of shipbuilding alloys. It contains a higher magnesium content than many other aluminum alloys, providing remarkable resistance to corrosion, which makes it particularly suitable for marine environments. When residing in adverse marine conditions, where exposure to saltwater is constant, the H116 and H321 tempers impart variable but optimized mechanical properties for different applications.

Working with 5083 marine-grade aluminum in thicknesses of 3mm, 5mm, and 10mm (specifically H116 and H321 tempers) is a daily reality for me. The H116, being the softer of the two, is easier to form and fabricate, making it ideal for parts requiring bending or drawing. We see a lot of demand for this in larger, less structurally demanding applications like cladding for marine vessels. However, the H321, with its higher strength, is a workhorse for components requiring greater structural integrity – think bulkheads, hull sections, or even specialized equipment mounts where corrosion resistance is paramount. The 10mm plates are a beast to handle, needing specialized machinery for cutting and processing, but the resulting product is incredibly robust. The 3mm and 5mm sheets are more manageable, offering a great balance between strength and workability. We regularly see these used in applications requiring lighter weight and excellent corrosion resistance.

One thing I've noticed over the years is the subtle differences in material behavior between the various thicknesses. While the alloy itself is consistent, the thicker plates tend to exhibit more pronounced springback after bending, requiring more precise tooling and more experience to handle effectively. Furthermore, the larger sheets at greater thicknesses pose significant challenges in terms of storage and handling to prevent warping or scratching. Quality control is essential throughout the process, from raw

H116 vs. H321 Temper Designations:

- H116 Temper:

- Characterized by strengthened and stress-relieved treatment, suitable for hull structures.

- Retains both corrosion resistance and robust mechanical performance at varying temperatures.

- Ideal for ship structures prone to cyclic loading.

- H321 Temper:

- Exhibiting enhanced toughness, particularly needed in can-overlapping situations or highly stressed components.

- Guarantees higher ductility and is typically utilized in heavier marine fabrication.

- This temper provides stability and sustains the dynamic behavior of structural components during usage.

Technical Specifications

Thickness Variations:

- 3mm Thickness: Ideal for lightweight components, such as cladding and paneling in yacht production or door frames. It’s flexible for machining with quality surface finishes, which is vital when aesthetic attributes come into play.

- 5mm Thickness: Versatile option providing both structural support and durability, commonly used in sections experiencing moderate stress, such as pathway panels, deckplates, and cabins.

- 10mm Thickness: Provides significant load-bearing capacity, crucial for primary structural components within vessels. Its resiliency helps in outfitting, helping ensure that integral parts stand sturdy against ocean currents and rough seas.

Functions and Applications of 5083 H116 and H321

1. Shipbuilding and Marine Architecture The applications of 5083 aluminum sheet plates are vast within the shipbuilding industry. Their resistance to seawater corrosion and excellent weldability make them optimal material choices for each phase of a vessel's construction, directly impacting safety and durability.

2. Offshore Industry Platforms and structures constructed for extraction or resource distribution rely on these aluminum plates for durability in harsh Wildlife zones. The rigidity helps support substantial weight requirements and environmental pressures, safeguarding valuable equipment stored above or harvested from beneath water surfaces.

3. Marine Convection Paneling and Decks Given their qualities, these alloys can promote innovative deck solutions that not only resists corrosion but provide thermal insulation beyond traditional materials, positioning these plates as advanced solutions replacing wood or steel counterparts.

https://www.alusheets.com/a/5083-h116-h321-3mm-5mm-10mm-thickness-marine-aluminum-sheet-plate.html