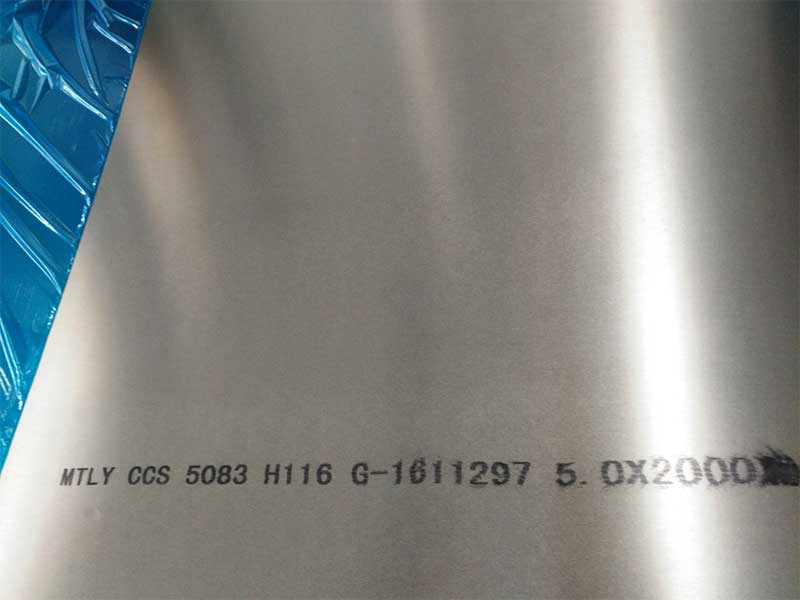

Marine aluminum alloy 5083 sheet mirror finish

Marine Aluminum Alloy 5083 Sheet Mirror Finish: A Distinctive Perspective

In the maritime environment, where materials are exposed to harsh elements and saline environments, the choice of materials significantly impacts the performance of vessels. Among those materials, marine aluminum alloy 5083 garners attention for integrating several mechanical and aesthetic benefits.

Alright, let's talk 5083 marine-grade aluminum sheet with a mirror finish. I've been working with this stuff for years here at the factory, and it's a unique beast. Most folks just see the shiny surface, but there's a lot more going on under the hood.

From a Production Standpoint:

Marine Aluminum Alloy 5083

Marine aluminum alloy 5083 is renowned for its exceptional resistance to corrosion, particularly due to its composition, which typically includes magnesium and a small proportion of manganese. However, it’s not only the alloy’s sturdy characteristics that make 5083 a preferred choice—it is also its versatility.

The alloy exhibits high strength and superior performance in cryogenic temperatures yet remains easy to work with, welding-friendly, and scalable in application. When processed into sheets with a mirror finish, aluminum alloy 5083 gains an elegant aesthetic to match its utility.

Features of 5083 Sheet Mirror Finish

-

Durability Meets Elegance: The mirror finish creates an avant-garde effect, accentuating surface recovery and interaction with light, making the material visually striking. This aesthetic aspect opens it to more applications, particularly in high-end recreational vessels.

-

Increased Resistance: The unique crystalline composition reduces porosity compared to other finishes, further prohibiting the onset of wear as the materials withstand severe corrosive oceans and prolonged exposure to the marine environment.

-

Structural Integrity: Notably stronger when cold-worked than many other aluminum grades, 5083 possesses tensile strength—providing the structural integrity necessary for applications where both performance and aesthetics coexist.

-

Workability: The alloy facilitates easy machining and acquirable sheen through various polishing methods. This enables extensive use in applications such as custom fabrication and marine construction where bespoke features are desired.

-

Lightweight Nature: Compared to traditional stainless-steel materials, 5083 offers lower density properties without compromising load capacity—emphasizing efficiency and operational productivity.

Applications—Where Possibilities Unite with Requirements

The marine aluminum alloy 5083 sheet mirror finish boasts a plethora of sophisticated applications encompassing architectural marvels to performance-driven maritime construction and recreation. Here are some applications from an attentive glimpse:

-

Yacht Building and Repair: In an industry underscored by excellence, aesthetics coupled with durability makes the alloy quintessential for high-end yachts’ superstructures. Designers incorporate 5083 because of its unmatched ability to uphold moisture-induced challenges while retaining a brilliant exterior that defines luxury.

-

Ship Welding and Fitting Components: Advanced shipbuilding often utilizes robust systems and complexes of parts requiring welding. The 5083 mirror finish offers superior compatibility with specific welding techniques catering to modern imaginative designs.

-

Marine Cushions and Reinforcements: Lightweight yet strong, 5083 mirror finish materials can aussi secure different components temporarily. Surfboards and marine turn tables could opt for designs reflecting light and stability under harsh wave impacts and season deterioration.

-

Architectural Details: Architectural firms integrate aluminum alloy 5083 for facades that connect functionality with aesthetic parties. External canopies, columns, and larger reflective designs use this material—not merely for looks but also sheer strength against wind pressures.

-

Signage and Public Displays: Many companies leverage the beautiful luminosity and extreme permanence of a mirror-finish surface, engaging substrate means ideal for longevity and visual impacts evident in busy seaports or logistical routes.

The Future of 5083 Sheet Mirror Finish

Growing trends across environmental campaigns tie back to the effectiveness of lighter structures against fossil fuels within design forecasting promising dynamism through upgraded processes. Scaling semi-modular kettle approaches provides future design avenues while continuing revolutionary s of weight against allure combined with robust structural integrity.

By integrating technology and keeping pace with burgeoning design imperatives, enthusiasts are right at the forefront.

https://www.alusheets.com/a/marine-aluminum-alloy-5083-sheet-mirror-finish.html