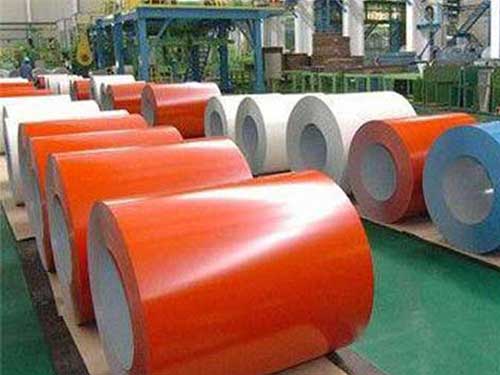

A1100 1060 1050 H24 Alloy Color Aluminum Coil

Understanding A1100, 1060, and 1050 H24 Alloy Color Aluminum Coils

Aluminum coil products are integral in various industries, providing flexibility and outstanding performance. Among the widely-used aluminum alloys, A1100, 1060, and 1050 H24 alloy color aluminum coils have become particularly popular due to their excellent attributes. With applications ranging from roofing to signage, understanding these coatings can significantly improve your production processes.

What are A1100, 1060, and 1050 H24 Alloys?

A1100 Alloy A1100 is known for its exceptional corrosion resistance, malleability, and thermal conductivity. This non-heat-treatable alloy boasts mechanical properties that make it easy to form and weld, which is advantageous for architectural applications. Primarily, A1100 finds use in food processing and chemical applications because of its clean finish not easily affected by convent chemical substances.

1060 Alloy The 1060 alloy composition contains approximately 99.6% aluminum, making it one of the purest grades available. This purity grants it remarkable corrosion resistance and thermal conductivity. As a non-heat-treatable alloy, it remains mechanically stable in various manufacturing processes—including rolling, forging, and extruding. It's particularly suitable for applications in electrical and solar industries due to its high conductivity rates.

1050 H24 Alloy The 1050 H24 alloy possesses about 99.5% aluminum content after cold-working, resulting in high ductility and strength. Its distinctive "H24" temper indicates it’s been substantially manipulated at elevated temperatures. This hardness level makes it apt for applications that require elasticity and sturdiness, like vehicle bodywork and building facades.

Features of Color Coated Aluminum Coils

One of the advantages of A1100, 1060, and 1050 H24 alloy types is their ability to incorporate color coatings. Boulevard Industries provide coated aluminum coils to enhance aesthetics and performance Kool-se hire কে-tone protection against environmental elements.

Here are a few significant benefits of color-coated aluminum coils:

-

Aesthetic Flexibility: Color coatings provide limitless possibilities for design choices, ensuring that it can fit into any architectural requirement or branded project demand.

-

Improved Durability: The coated layer protects the underlying aluminum from threatening factors, including UV rays, corrosion from chemicals, and physical wear and tear.

-

Easy Maintenance: Color-coated surfaces typically require minimal maintenance. Their smooth surfaces do not allow dust adhesion, making them easy to clean and reduce upkeep costs.

-

Energy Efficient: Certain reflective coatings can minimize heat absorbed by the structure, improving energy efficiency.

Applications of A1100, 1060, and 1050 H24 Alloy Color Aluminum Coils

Due to their versatile nature and performance-enhancing features, these aluminum coil alloys are suitable for several essential applications:

- Building and Construction: Perfect for roofing, siding, decorative elements, and facades.

- Manufacturing: Commonly used in domestic appliances, vehicles, and mobile homes.

- Packaging Industry: The non-reactive nature of A1100 promotes safety and sustainability in food packaging.

https://www.alusheets.com/a/a1100-1060-1050-h24-alloy-color-aluminum-coil.html