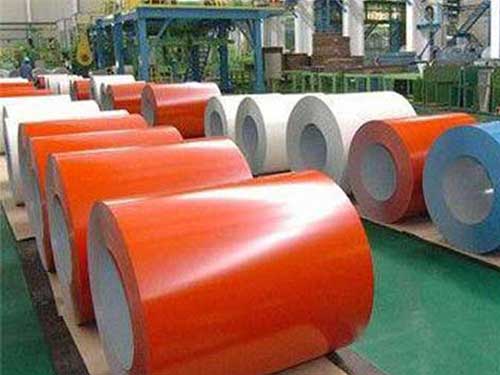

Coated Aluminium Coil 1070 1050 1060

Aluminium has long been a material of choice in various industries due to its lightweight, high strength, and excellent corrosion resistance. Among the vast array of aluminium alloys, coils made from 1070, 1050, and 1060 offer unique characteristics that enhance their usability across multiple applications, particularly when subjected to a coating process. The coating adds value by improving aesthetic appeal, resistance to external factors, and durability.

Features of Coated Aluminium Coil 1070, 1050, 1060

1. High Purity

- 1070 Alloy: This variant contains a minimum 99.7% aluminium, making it excellent for electrical conductors and chemical applications. Its high purity level is essential for environments where conductivity and resistance to oxidation are critical.

2. Workability and Formability

- 1050 and 1060 Alloys: With high elongation, these alloys offer superior workability that makes them remarkably adaptable. This property is vital for applications requiring complex shapes, such as in home appliances and consumer electronics.

3. Resistance to Corrosion

- The coated surface significantly enhances the natural corrosion resistance of these alloys. This is especially valuable in softer climates and marine environments where exposure to seawater and salt can lead to damage and deterioration over time.

4. Lightweight Strength

- Aluminium’s natural strength-to-weight ratio renders it ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries. The coated coils also maintain structural integrity while providing improved insulation over their uncoated counterparts.

5. Aesthetic Versatility

- Coated finishes in a plethora of colors and textures not only enhance the visual aspect of the material but also add protective properties. This quality is particularly beneficial in construction and architectural applications, where appearance and durability are equally significant.

Applications of Coated Aluminium Coil 1070, 1050, 1060

1. Construction and Architecture

The architectural industry frequently utilizes coated aluminium coils for façades, roofing systems, gutters, and rain-carrying solutions. The appealing finishes cater to modern design aesthetics while providing reinforcement against environmental factors.

2. Automotive Parts

The lightweight characteristics coupled with the coating's impact resistance result in applications in automotive trim, decorative elements, and structural parts, all of which enhance a vehicle’s efficiency without compromising safety.

3. Electrical and Electronics

Due to their high conductivity and corrosion resistance, coated aluminium coils are ideal for making electrical cables, heat sinks, and components in home appliances. The coatings serve as an insulator, further enhancing their applications in electronics.

4. HVAC Systems

Application in heating, ventilation, and air conditioning systems is prominent, utilizing the coated coils in ducting and various components. Their lightweight nature and resistance to water and airborne contaminants make them a reliable choice for optimal performance.

5. Consumer Goods

Coated aluminium coils are increasingly found in manufacturing premium consumer goods, from kitchen utensils to household appliances, where appealing looks paired with durability are paramount.

6. Transportation

These coated materials are extensively found in public transit systems, such as buses and trains, contributing to an overall reduction in vehicular weight without sacrificing strength and safety features.

https://www.alusheets.com/a/coated-aluminium-coil-1070-1050-1060.html