Alloy 1050 Solar Mirror Finish Aluminum

In an era where renewable energy and sustainable practices take center stage, Alloy 1050 Solar Mirror Finish Aluminum stands out as more than just an industrial material—it's a conduit for innovation in the solar energy sector. While many may see aluminum merely as a lightweight metal used for a range of applications, the attributes and capabilities of this particular alloy reveals its critical role in fostering a greener future.

A Look into Alloy 1050

Alloy 1050 is primarily composed of 99.5% or higher aluminum, making it one of the purest forms available. This purity is essential because it directly contributes to exceptional conductivity—both thermal and electrical—and excellent workability that allows for complex fabrication. As we pivot toward applications in solar mirrors, these inherent characteristics unfold from technical specifications into practical, real-world benefits.

Working with Alloy 1050 Solar Mirror Finish Aluminum presents a unique set of challenges and rewards. Its high purity and inherent reflectivity make it ideal for solar applications, but achieving that consistently brilliant "mirror" finish requires meticulous control throughout the production process. We're constantly tweaking parameters on our rolling mills, ensuring consistent gauge and surface smoothness. A tiny imperfection, a microscopic scratch, can dramatically reduce the sheet's reflectivity and ultimately its effectiveness in capturing sunlight. The slightest variation in the chemical etching or anodizing stages can also affect the final finish, so constant monitoring and quality checks are paramount. It's fascinating to see how such a seemingly simple material demands such precision.

Personally, what I find most rewarding about working with 1050 Solar Mirror is the tangible impact it has. Knowing that the sheets I help produce contribute to a cleaner, more sustainable energy future is immensely satisfying. We regularly see improvements in our processes, pushing the boundaries of reflectivity and durability. The quest for a perfectly reflective surface isn't just about aesthetics; it's about maximizing energy efficiency and minimizing environmental impact. That's what makes working with this particular aluminum alloy so fulfilling – it's not just metal; it's a component in a larger, positive change.

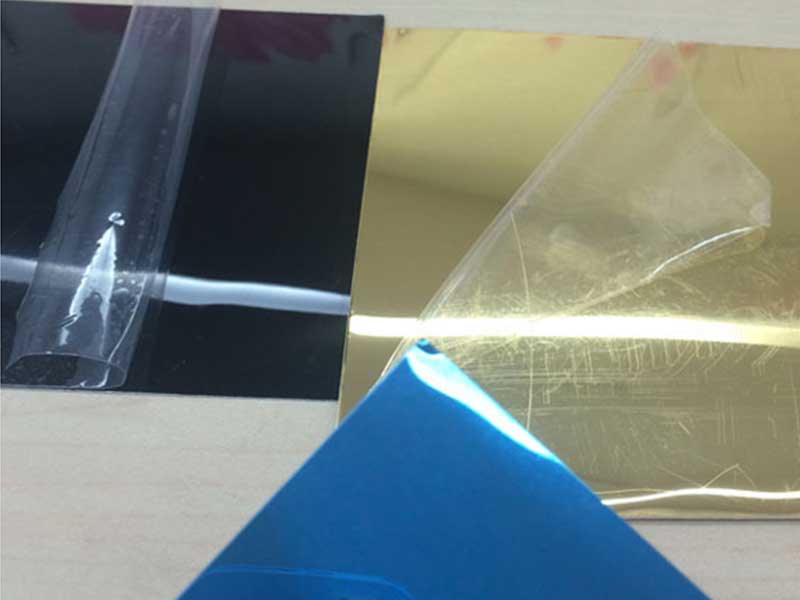

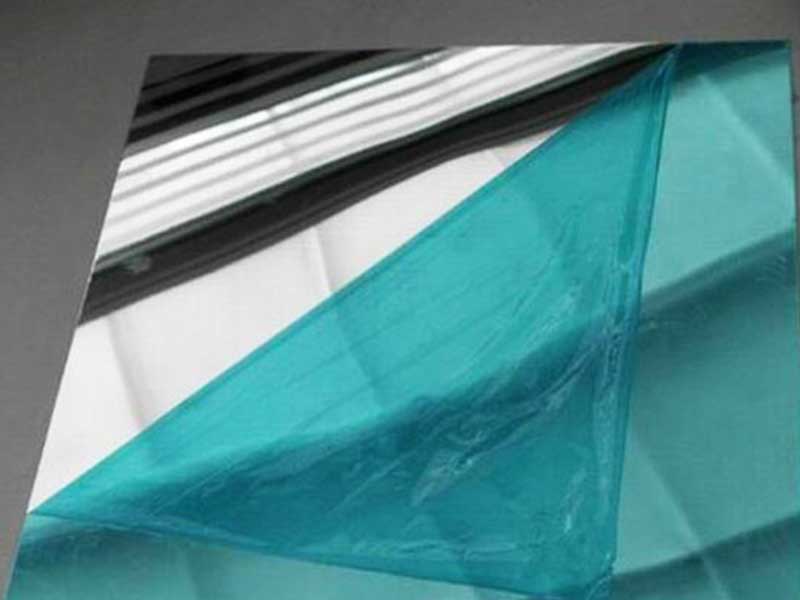

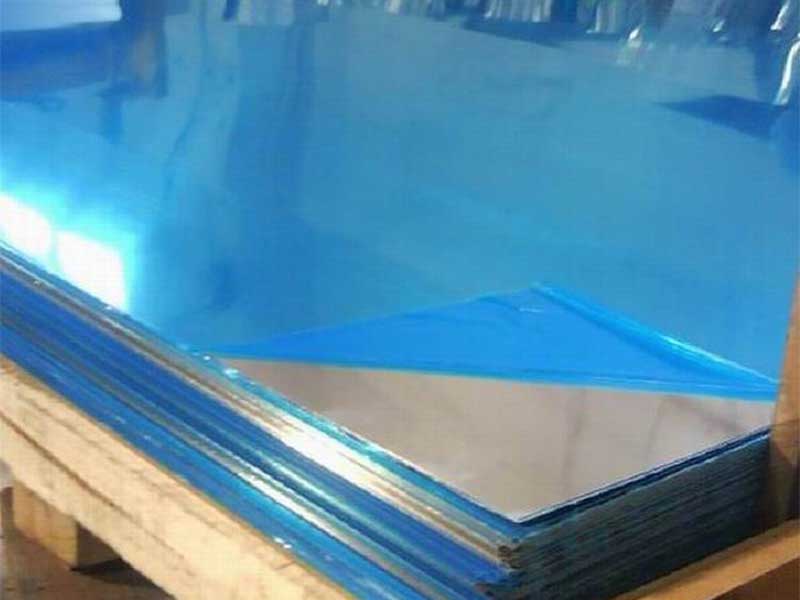

The Solar Mirror Finish

The finishing process that defines the Alloy 1050 Solar Mirror involves specially treating the surface to create an ultra-smooth, reflective quality. This process is critical because it enhances the material's ability to reflect sunlight, maximizing the efficiency of solar thermal collectors and photovoltaic panels. The mirror finish not only captures more solar energy but also does so with a minimal environmental footprint.

Sustainability Meets Performance

Reflecting upon the goals of a sustainable future reveals how integral materials like Alloy 1050 can be. Traditional energy sources often leave irreversible damage to the environment, while Alloy 1050 is wholly recyclable, aligning perfectly with circular economy principles. When we invest in solar technologies, we invest in materials that reduce waste and promote a greener planet. Consequently, the decision to adopt this alloy goes beyond engineering; it symbolizes a commitment to sustainability.

Versatile Applications Beyond Solar Energy

While its contribution to solar technology is staggering, Alloy 1050's applications stretch far beyond the realm of reflectors. In signage, lighting fixtures, and architectural elements, this alloy caters to industries where aesthetics and functionality meet. Simple yet elegant, the products crafted from this alloy enhance visual appeal while ensuring strength, leaving a substantial impact in every application.

A New Perspective on Manufacturing

Examining Alloy 1050 through a lens of sustainability yields insight into the manufacturing process as well. Generally, its adept malleability allows designers and manufacturers to create custom shapes for varied applications, leading to minimal resource waste. Implementing this alloy also propels the shift toward advanced manufacturing techniques whereby materials are employed most efficiently, ultimately aiding in lower overhead costs and bolstering the economy.

https://www.alusheets.com/a/alloy-1050-solar-mirror-finish-aluminum.html