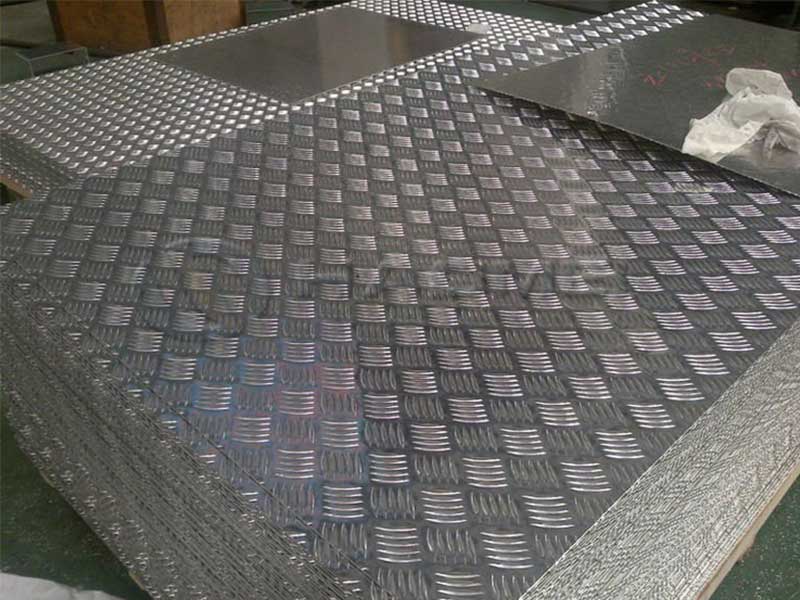

Aluminum tread plate 1100 1050 3003 5052 6061

Unveiling Aluminum Tread Plates: Technical Insights into Series 1100, 1050, 3003, 5052, and 6061

Aluminum tread plates form a cornerstone in both aesthetics and functionality across various industries due to their unique properties and versatility. the nuances between different alloy series is to harnessing their full potential.

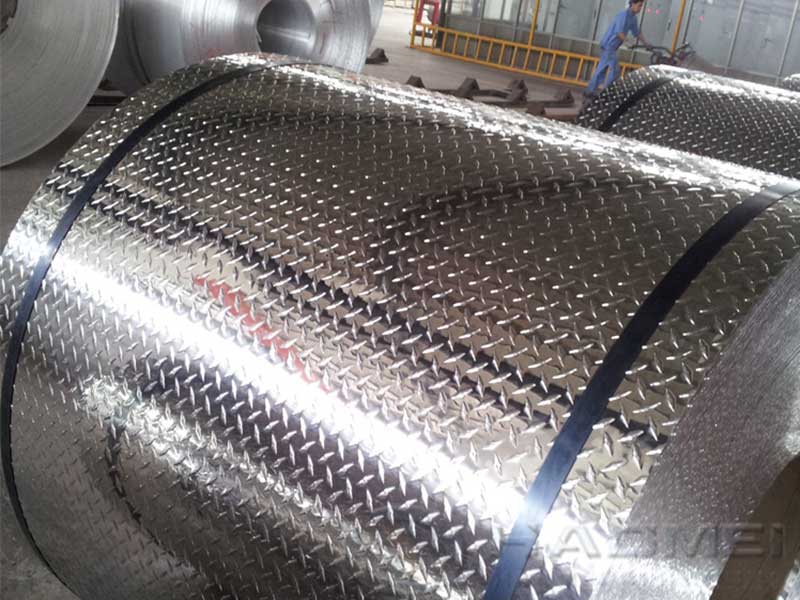

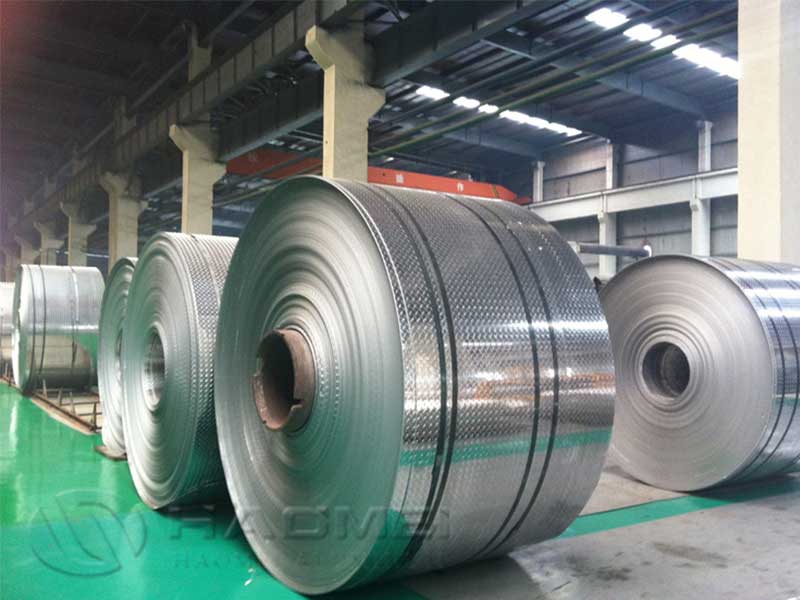

Working with aluminum tread plate in alloys 1100, 1050, 3003, 5052, and 6061 reveals distinct processing and application characteristics. The softer alloys, 1100 and 1050, are excellent for ease of fabrication – punching, bending, and forming are straightforward. However, their lower strength limits their use to applications with less demanding load requirements, like decorative panels or low-traffic walkways. Conversely, 6061, a heat-treatable alloy, offers significantly improved strength and durability, making it ideal for heavy-duty applications such as truck beds or industrial platforms where wear and tear are substantial. We often see 3003 used in applications needing a balance between formability and strength, while 5052, known for its excellent corrosion resistance, finds its niche in marine or outdoor environments where longevity is paramount, even if it means compromising slightly on formability.

The choice of alloy is critically linked to the final product’s intended use and the customer's budget. For instance, while 6061 offers superior strength, its higher cost may make 3003 a more economical substitute for less demanding applications. the subtle differences in workability – some alloys require specific lubricants during forming to avoid cracking – is crucial for efficient production and minimizing scrap. We’ve learned that optimizing the cutting parameters

1. Alloy 1100: The purist's choice

Aluminum tread plate 1100 boasts a composition of over 99% pure aluminum. With its exceptional workability and resistance to corrosion, it excels in environments where purity matters most, such as food processing. Its electrical conductivity is unmatched, making this alloy excellent for applications requiring reliable electrical conductance it has low structural capability, suitable for more decorative functions.

Unique Insight: In spaces where hygiene is paramount, opting for 1100 tread plate can enhance aesthetics while providing a clean working environment.

2. Alloy 1050: Industry newcomer’s best friend

Similar to 1100, the 1050 series is characterized by its copper-free composition and robustness. Its relatively soft design makes it highly malleable, which is imperative for intricate shapes required in design. This aluminum tread plate caters benefit particularly in specialized fabrication where accuracy is critical.

Unique Perspective: Often overlooked, the 1050 tread plate is ideal for projects where artistic design takes precedence without sacrificing structural integrity.

3. Alloy 3003: The rising performer

With added strength from manganese, aluminum tread plate 3003 presents a more robust solution for general use. Its moderate weight gives it enhanced resistance against the elements, making it a staple across commercial decks and interior surfaces. The lightweight properties ensure easy installation—huge benefits for long-standing wear and application in aluminum flooring.

Unique Insight: The structural balances of alloy 3003 stand as a testament to how innovation pivots around enhanced functionality—even at a cost-effective measure.

4. Alloy 5052: The more resilient choice

As we advance into thicker gauge inclinations, the 5052 tread plate arrives as a embodies strength and flexibility. Magnesium additions amplify its resilience, rendering it perfect for marine and road construction applications where robust external pressures are highlighted within compound environments.

Distinctive Perspective: Relying on 5052 provides manufacturers with ideal energy absorption properties ensuring longevity against corrosion induced failures.

5. Alloy 6061: The multitasking heavyweight

6061 aluminum tread plate combines magnesium and silicon to yield an excellent option for structural applications. Optimal for exacting demands, its weldability makes it vital in crucial frameworks—something aligning perfectly with the needs of both vehicle manufacture and aerospace designs.

Unique Takeaway: The presence of alloy 6061 on site signifies not only quality but also proficient integration into complex multi-component needs, reinforcing the claim to aluminum's leadership role in engineering materials.

https://www.alusheets.com/a/aluminum-tread-plate-1100-1050-3003-5052-6061.html