Aluminium Coil 1050 1060 1070 Temper

Understanding Aluminium Coil 1050, 1060, and 1070 Temper: Features and Applications

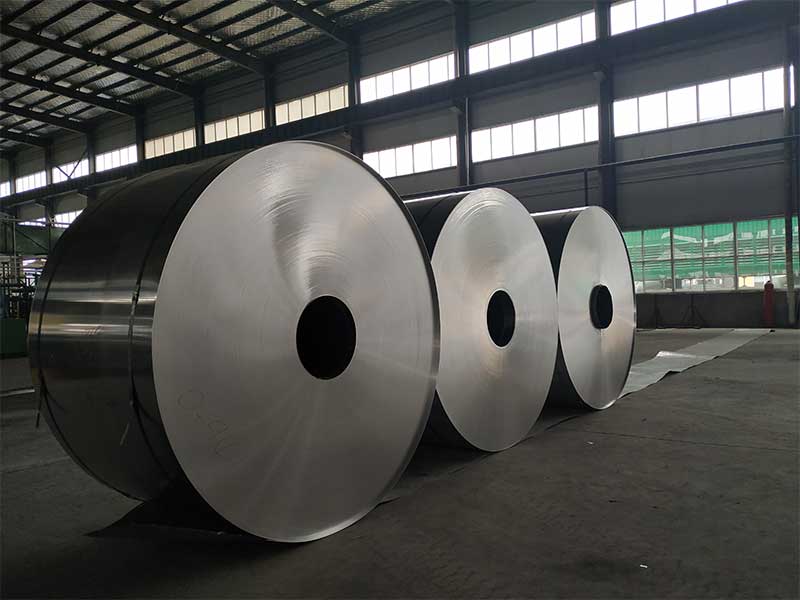

Aluminum coils have become integral to various sectors due to their lightweight, corrosion resistance, and adaptability. Among the many grades of aluminum available, Aluminum Coil 1050, 1060, and 1070 stand out. These grades provide distinct features and applications that cater to multiple industries.

Unique Features

- Chemical Composition Aluminum Coils 1050, 1060, and 1070 are part of the 1xxx series of aluminum, where the first digit indicates that the alloy contains 99% or higher aluminum content. Specifically:

- Aluminium 1050: With an aluminum content of 99.5%, this grade is highly malleable and has excellent corrosion resistance.

- Aluminium 1060: Featuring a minimum aluminum content of 99.6%, 1060 alloys offer great workability and thermal conductivity.

- Aluminium 1070: Slightly higher in purity, typically at 99.7%, 1070 exhibits exceptional electrical conductivity and formability.

- Temper Variants The temper of aluminum is classified based on the fabrication processes it has undergone. Common tempers for these grades include H14 and H24, reflecting work-hardening and strain-hardened conditions. - H14: Represents partially hardening; it provides some degree of strength along with greater ductility.

- H24: Indicates a strain-hardened, low-strength variety, providing enhanced conformability during manufacturing.

- Physical Properties May Include:

- Lightweight: Provides ease of handling and reduces shipping costs.

- Excellent Workability: Adaptable for either cold rolling or stamping processes.

- High Electrical and Thermal Conductivity: Critical for applications in electrical and thermal devices.

Practical Applications

-

Electrical Conductors One of the most notable applications of Aluminum Coil 1050, 1060, and 1070 is in the electrical industry. These alloys are highly conductive, making them ideal for electrical wires, cables, and capacitors. Their durability ensures longevity, resulting in lower maintenance costs.

-

Plates and Sheets for Chemical and Food Processing Industries With their superior corrosion resistance, especially in additive treatment, these alloys serve well in manufacturing plates and sheets used in chemical and food processing industries. They can withstand cleaning agents and processes, making them perfect for environments requiring hygiene and safety standards.

-

Reflectors and Lighting Fixtures The high reflectivity of aluminum in the 1050, 1060, and 1070 tempers makes them an excellent choice for reflectors. Their thermal properties ensure efficient light behavior, thereby contributing to energy savings and improved visibility in both commercial and residential lighting applications.

-

Decorative Applications The aesthetic appeal and availability in various finishes allow these aluminum coils to be used in decorative applications, such as architectural elements and signage products. Their ability to maintain form and structure without rapid degradation is essential in these roles.

-

Heat Exchangers and Cooling Devices Given their thermal conductivity, both 1060 and 1070 alloys are commonly utilized in the manufacturing of heat exchangers, radiators, and HVAC systems. The effective heat transfer attributes ensure optimal performance in cooling applications.

https://www.alusheets.com/a/aluminium-coil-1050-1060-1070-temper.html