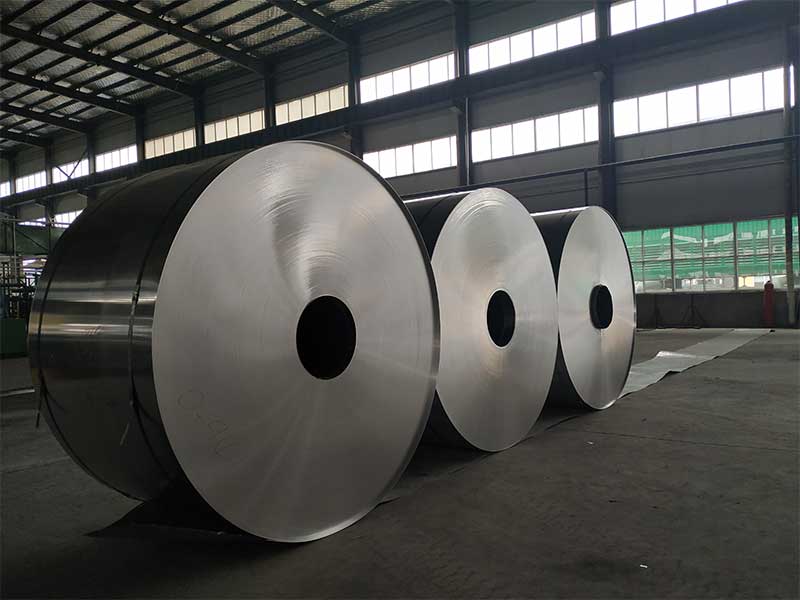

Aluminum coil ASTM standard 1100 1050 1020 1060

Aluminum coils have become critical materials across various industries, thanks to their versatility, lightweight properties, corrosion resistance, and ease of fabrication. Within the realm of aluminum, ASTM standards help ensure quality and performance. The specific grades ASTM 1100, 1050, 1020, and 1060 exhibit unique characteristics that make them suitable for different applications.

Overview of ASTM Grades

- ASTM 1100: This is a highly pure aluminum alloy (99% minimum aluminum content). It’s known for its excellent corrosion resistance, good formability, and superior conductivity.

- ASTM 1050: With a slightly lower purity (99.5% aluminum), this alloy combines similar characteristics to 1100 but provides a higher strength level.

- ASTM 1020: This is a high-purity aluminum with 99.7%. Like that of 1100 and 1050, the properties focus on electrical conductivity. However, it’s mainly prized for its high softness and ease of fabrication.

- ASTM 1060: Offering an aluminum content of 99.6%, 1060 shares similarities with 1050 but provides slightly better mechanical properties, making it equally popular for various manufacturing processes.

Features

-

Corrosion Resistance: All grades—from 1100 to 1060—exhibit exceptional resistance to moisture and corrosion, making them ideal for applications exposed to the elements. This property ensures longevity, even in the harshest environments.

-

Weight and Strength: The lightweight nature of aluminum coils accounts for high tensile strength-to-weight ratios. For industries like aerospace and transportation, this becomes vital for building efficient structures with reduced overall weight without compromising strength.

-

Thermal and Electrical Conductivity: These aluminum grades are excellent conductors of heat and electricity, particularly noteworthy are 1100 and 1050, useful in electrical equipment manufacture yielding low resistance, thus improving efficiency.

-

Machinability and Formability: The alloys exhibit high formability and can be easily manipulated to fit specific shapes and applications. They are suitable for cold working techniques without extensive pre-heating.

Applications

The application range of ASTM grades 1100, 1050, 1020, and 1060 is extensive:

-

Food and Beverage Industry: ASTM 1100 is favored for its high corrosion resistance, making it suitable for applications like heat exchangers and chemical storage equipment.

-

Electrical Conductors and Equipment: 1050 is regularly used in manufacturing electrical components, such as wiring and transformer windings, benefitting from its impactful electrical conductivity.

-

Aerospace and Automotive Manufacturing: The reduced weight and adequate strength of each aluminum coil are applied in the automotive industry for body panels, parts, and structures to improve fuel efficiency while maintaining safety very effectively.

-

Building and Construction: These alloys are widely used in architectural applications for roofing sheets, siding, and window frames due to their durability and aesthetic appeal.

-

Heat Exchangers and Cooling Equipment: Grade 1060, thanks to its excellent thermal conductivity, finds use in systems designed for heat exchange and cooling applications.

https://www.alusheets.com/a/aluminum-coil-astm-standard-1100-1050-1020-1060.html