Aluminium sheet roll

Aluminium sheet rolls are becoming increasingly integral in various industries, thanks to their lightweight, durability, and versatility. Whether you're in construction, automotive, aerospace, or manufacturing, these rolled sheets can significantly enhance your project's efficiency and performance.

What are Aluminium Sheet Rolls?

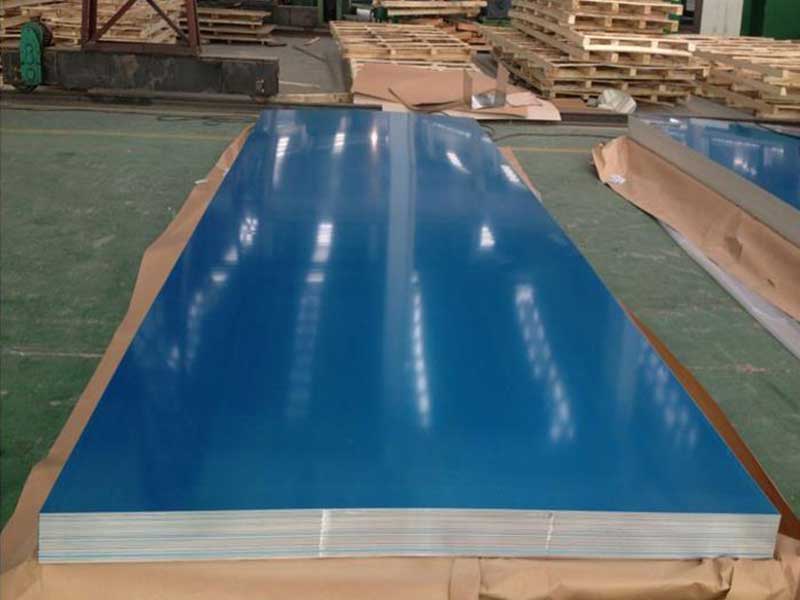

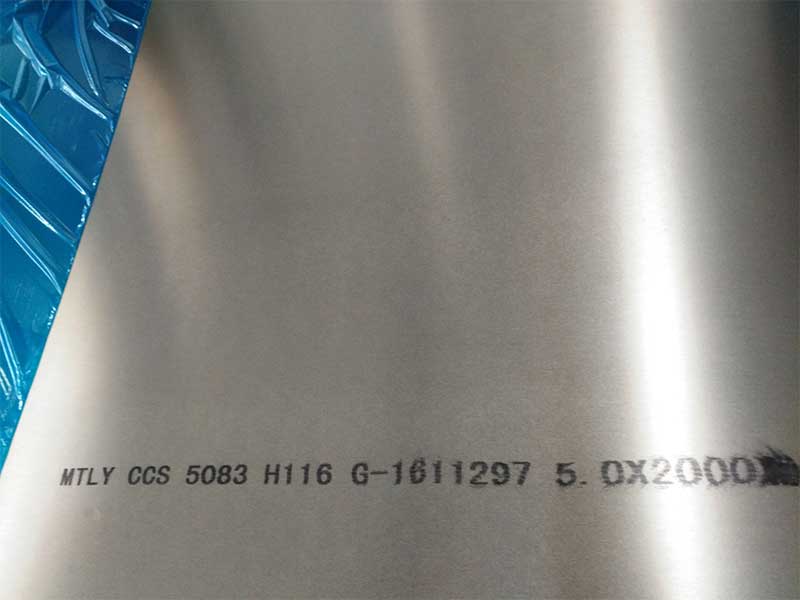

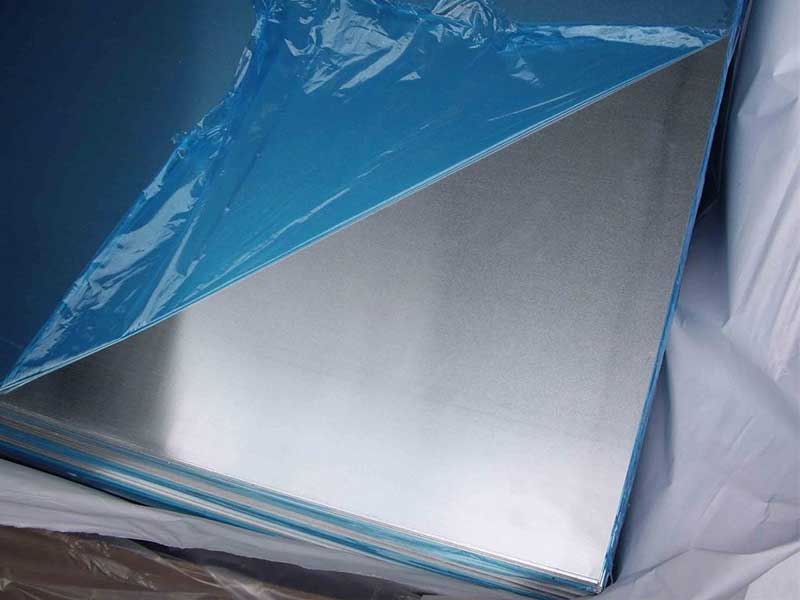

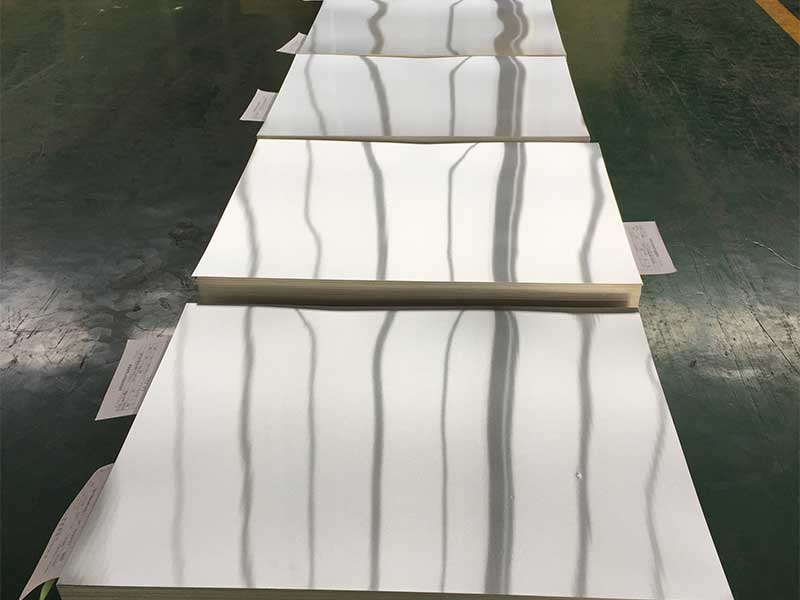

Aluminium sheet rolls refer to thin sheets of aluminum that have been coiled for storage and transportation. Typically produced in thicknesses ranging from 0.2 mm to several millimeters, they can be easily cut and manipulated to meet specific design and manufacturing requirements. The significant feature of aluminum sheet rolls is their ability to be processed into various forms while maintaining structural integrity.

Features of Aluminium Sheet Rolls:

-

Lightweight: Aluminium weighs approximately one-third that of steel, making it an ideal material for applications across many industries. This lighter weight contributes to lower transportation costs and ease of handling.

-

Corrosion Resistance: One of the most appealing characteristics of aluminium is its natural resistance to corrosion due to the formation of a protective oxide layer. This feature is especially advantageous in outdoor or marine environments where materials must withstand harsh conditions.

-

Malleability and Formability: Aluminium sheet rolls can be readily formed into intricate shapes and profiles. The ability to mold and design intricate components makes them a key material in creative applications in architecture, decor, and functional frameworks.

-

Conductivity: Both thermal and electric conductivity are important properties for numerous industries. Aluminium is known for its excellent heat and electrical conductivity, making it an appropriate choice, especially in electrical and electronic applications.

-

Recyclability: Environmental responsibility is classrooms in modern manufacturing, and aluminum excels in this aspect as well. Aluminium is 100% recyclable without any loss in quality, promoting a truly sustainable lifecycle that is in sync with today’s environmental commerce values.

Applications of Aluminium Sheet Rolls

The applicability of aluminium sheet rolls extends across a spectrum of industries owing to their ideal blend of features:

1. Construction Industry

In the construction sector, aluminium sheet rolls are widely used for both functional and decorative purposes. They are integral to roofing panels, insulated panels, cladding systems, and window frames. The combination of lightweight, weather-resistant properties makes aluminum an efficient choice for months-long construction periods where robust yet manageable materials are necessary.

2. Automotive Industry

Automakers are emphasizing fuel efficiency and lightweight bodies without sacrificing safety. Aluminium sheet rolls have significant traction in the automotive industry, as they contribute to lighter vehicle frames and body panels. This reduction in energy consumption not only leads to better fuel efficiency but aligns with the industry's goals of reduced environmental impact.

3. Manufacturing and Fabrication

Ranging from air conditioning units and kitchen appliances to structural components in furniture manufacturing, aluminium sheet rolls are pivotal in the realms of manufacturing and fabrication. The material's strength-to-weight ratio enhances product reliability while providing versatility in design.

4. Packaging

Due to excellent barrier properties, aluminium sheet rolls are increasingly used in packaging. They offer moisture, gas, and light impedance, making them ideal for food and medical goods where product integrity is paramount.

5. Aerospace Industry

The aerospace sector demands materials that meet stringent safety and performance standards. Aluminium sheet rolls meet these requirements, as their lightweight structure contributes to overall aircraft efficiency—as well as performance oftentimes at high speeds and altitudes.