Aluminium Sheet Aa5083 Aa5251 O H32

Aluminium sheets are vital components in various industries, thanks to their excellent strength-to-weight ratio, corrosion resistance, and versatile applications. Among the numerous alloys available, Aluminium AA5083 and AA5251 O H32 stand out due to their exceptional mechanical properties and suitability for a diverse range of projects.

Understanding Aluminium Alloys

Aluminium alloys are categorized into two main groups: wrought and cast alloys. AA5083 and AA5251 belong to the wrought alloy category, mainly used for applications demanding good weldability and corrosion resistance. The 'AA' in their designation indicates they are registered with the Aluminum Association, reflecting their established standards in design and manufacturing.

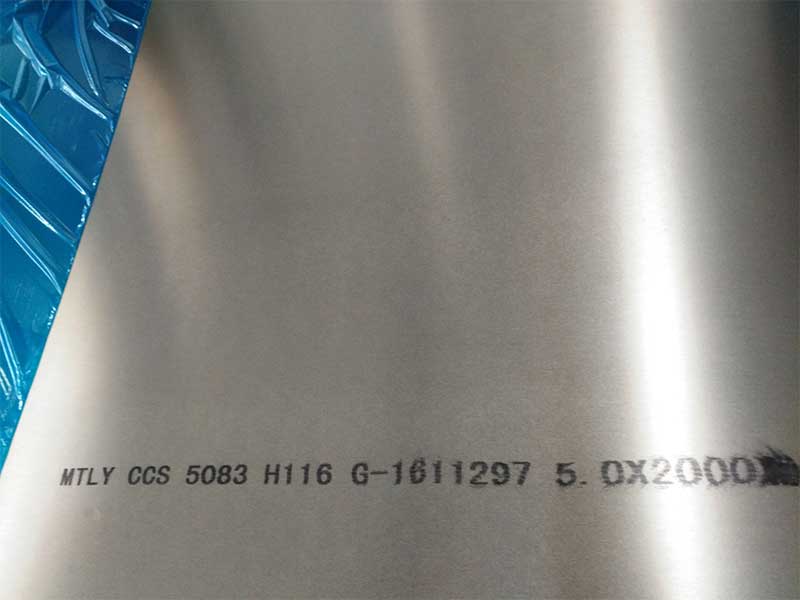

Characteristics of AA5083 Aluminium Sheet

Aluminium Alloy 5083 is well-known for its outstanding performance in extreme environments. Its composition includes magnesium as the primary alloying element, which gives it an incredible ability to resist stress corrosion cracking. Here are some of its key properties:

-

Corrosion Resistance: AA5083 exhibits excellent resistance to marine environments, making it an ideal choice for shipbuilding and offshore applications.

-

Strength: It boasts a high yield strength, making it suitable for heavy-duty applications in the construction and transport sectors.

-

Weldability: This alloy performs exceptionally well when welded, ensuring structural integrity and durability in applications like pressure vessels and trailers.

Features of AA5251 Aluminium Sheet

Aluminium Alloy 5251 is another exceptional alloy, mainly alloyed with magnesium and known for its moderate strength and good workability. Its characteristics include:

-

Formability: AA5251 exhibits excellent forming characteristics, making it suitable for demanding applications, such as deep drawing in vehicle panels.

-

Corrosion Resistance: Similar to AA5083, AA5251 also offers remarkable resistance to corrosion, particularly in chloride environments, making it perfect for architectural applications.

-

Lightweight: Combining strength with low density, AA5251 is an ideal choice for weight-sensitive applications in transportation, including truck bodies and shipbuilding.

Comparison of AA5083 and AA5251 O H32

While both alloys offer significant benefits, choosing between AA5083 and AA5251 O H32 often depends on specific project requirements. AA5083 is typically favored for projects requiring high strength and significant resistance to corrosion, making it popular in marine constructions. On the other hand, AA5251 O H32 excels in applications where forming capabilities and corrosion resistance are both crucial but at a lower overall strength.

H32 designation specifically indicates that the material has been work-hardened with a specific amount of strain and is partially annealed. This results in a balance between strength and ductility, an important factor in creating intricate shapes and frameworks.

Applications of AA5083 and AA5251 Aluminium Sheets

Both AA5083 and AA5251 aluminium sheets find extensive applications across multiple industries, including:

-

Marine Industry: Utilized in the construction of ships and yachts due to their excellent corrosion resistance and durability in saline conditions.

-

Automotive Sector: Employed for manufacturing panels and bodywork in vehicles, taking advantage of their lightweight and strength.

-

Construction: Ideal for structural applications, ceilings, and wall panels, thanks to their enhanced aesthetics andformability.

https://www.alusheets.com/a/aluminium-sheet-aa5083-aa5251-o-h32.html