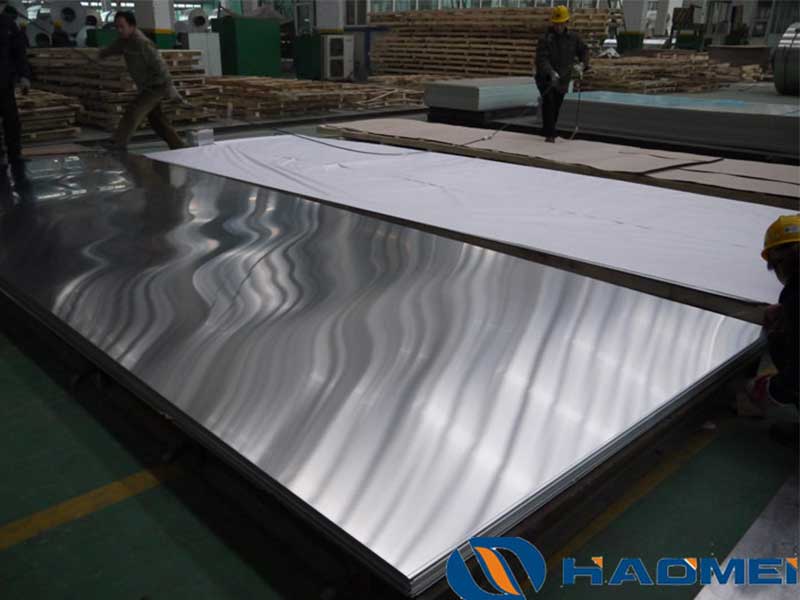

T3 T8 Aluminium sheet For Transportation

In the ever-evolving landscape of the transportation industry, weight reduction, strength, and durability are crucial factors that influence performance, safety, and efficiency. As manufacturers and engineers strive to create innovative solutions, T3 and T8 aluminum sheets have gained prominence due to their exceptional properties.

Understanding T3 and T8 Aluminum Alloys

T3 and T8 refer to specific temper designations within the 2000 and 6000 series of aluminum alloys, respectively. These tempers indicate the alloys' state of treatment:

- T3 Temper: Aluminum in this temper is solution heat-treated and cold worked. It provides excellent strength, making it suitable for applications where structural integrity is paramount.

- T8 Temper: Aluminum in the T8 temper has been solution heat-treated and subsequently artificially aged. This leads to improved strength and enhanced workability, providing an optimal balance for various manufacturing processes.

Both T3 and T8 aluminum sheets are lightweight yet robust, offering excellent machinability and formability, which are critical attributes for transportation-related applications.

Applications in Transportation

1. Aerospace Industry

The aerospace sector requires materials that can withstand extreme conditions while maintaining minimal weight. T3 aluminum sheets are frequently utilized in the airframe components and lifting surfaces of aircraft due to their high strength-to-weight ratio. Additionally, T8 sheets are often used for components needing increased resistance to fatigue and thermal stress.

2. Automotive Manufacturing

In the automotive industry, where fuel efficiency is key, T3 and T8 aluminum alloys offer lightweight alternatives to traditional materials. From body panels to structural elements, the use of these aluminum sheets helps reduce vehicle weight, improving fuel consumption and lowering emissions. Manufacturers also favor these tempers for their corrosion resistance, contributing to the longevity of vehicles.

3. Rail Transport

Rail vehicles face unique stresses and require materials that can endure long-term exposure to varying climates and environments. T3 aluminum sheets are favored in the construction of train bodies, while T8 sheets are used in parts that experience higher wear and tear. The combination of strength and lightweight characteristics helps optimize fuel efficiency while providing excellent load-bearing capabilities.

4. Marine Applications

T3 and T8 aluminum sheets are popular in the marine sector, where corrosion resistance is essential due to exposure to saltwater and harsh environments. Boats and ships manufactured with these alloys can achieve better performance and increased service life, something highly prioritized in the demanding marine setting.

Benefits of Using T3 and T8 Aluminum Sheets

When integrated into transportation applications, T3 and T8 aluminum sheets provide a wide range of benefits:

- Strength and Durability: Both tempers exhibit high tensile strength, crucial for components exposed to mechanical stresses.

- Weight Reduction: The lightweight nature of aluminum contributes to overall reduction in vehicle weight, enhancing efficiency across various transportation vehicles.

- Corrosion Resistance: Aluminum's resistance to corrosion ensures the longevity and reliability of components, minimizing maintenance costs and downtime.

- Versatility: Both T3 and T8 alloys have impressive formability, allowing manufacturers to create parts of various shapes and sizes without compromising integrity.

https://www.alusheets.com/a/t3-t8-aluminium-sheet-for-transportation.html