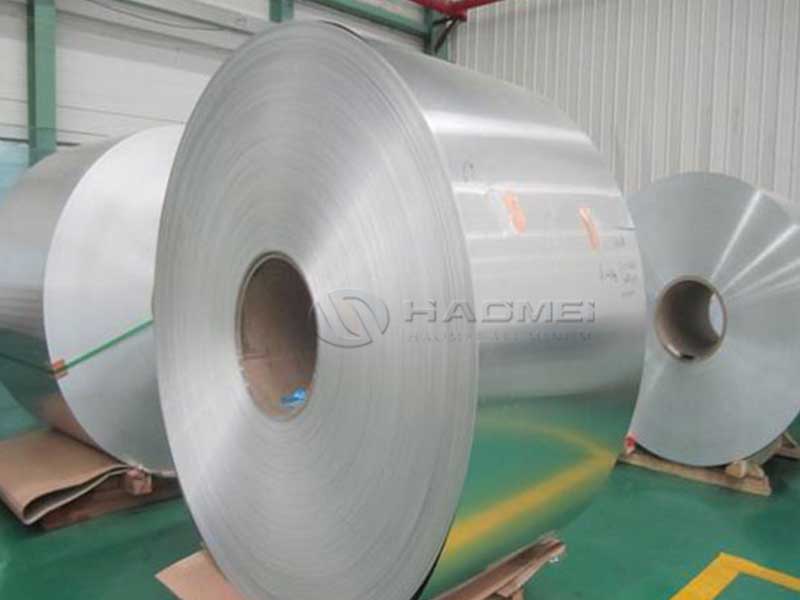

3003 Aluminum Foil

The Versatile World of 3003 Aluminum Foil: Functions and Applications

When it comes to aluminum foils, 3003 aluminum foil stands out for its remarkable versatility and reliability.

Working with 3003 aluminum foil daily, I've come to appreciate its unique blend of properties. It's not as strong as some of our higher-strength alloys, but its workability is a major plus. We use it extensively in applications requiring deep drawing or forming – think food packaging, particularly those requiring complex shapes or intricate folds. The slight increase in cost compared to, say, 1050, is usually justified by the improved formability, reducing scrap and speeding up production. I've seen firsthand how its moderate strength coupled with good corrosion resistance makes it ideal for applications needing both structural integrity and protection from moisture and oxidation. This alloy is a workhorse, constantly proving its worth in the demands of our high-speed production lines.

Beyond the technical specs, there's a certain satisfaction in handling 3003. Its slightly softer texture compared to harder alloys makes it easier to handle during the manufacturing process. We occasionally encounter issues with surface imperfections, often related to rolling inconsistencies, but our team has developed sophisticated quality control measures to mitigate these problems. Honestly, troubleshooting these minor defects feels like solving a little puzzle. Knowing that this seemingly simple sheet of foil will end up protecting food, protecting pharmaceuticals, or even providing a barrier in various industrial settings is incredibly rewarding. It's a testament to the importance of even the most seemingly mundane materials in our everyday lives.

3003 Aluminum Alloy

Before examining the applications of 3003 aluminum foil, it’s essential to comprehend its composition and characteristics. The 3003 alloy, mainly composed of 97% aluminum and approximately 1% manganese, falls under the 3xxx alloy series. Its unique formulation provides several technical strengths, including:

-

Corrosion Resistance: 3003 aluminum foil has excellent resistance to corrosion, especially in industrial environments. This makes it ideal for applications susceptible to oxidizing environments.

-

Formability: Due to its ductility, 3003 is highly malleable, allowing it to be easily shaped and formed without cracking. This attribute is crucial for applications requiring tight bends and folds.

-

Workability: Its low density and good machinability mean it can be fabricated efficiently. This inherent property makes 3003 suitable for mass production.

-

Weldability: With superior weldability, this aluminum alloy easily integrates with other materials, which broadens its range of potential applications.

Applications of 3003 Aluminum Foil

- Food Packaging and Storage

One of 3003 aluminum foil’s primary functions is food packaging. Its high barrier protection prevents light, moisture, and oxygen exposure, allowing for prolonged preservation of freshness and flavor. This is especially important for items like baked goods, snacks, or ready-to-eat meals. Because 3003 aluminum foil can provide both insulation and a shelf-stable environment, food products can be delivered safely to consumers without the risk of spoilage.

- Household Use

In kitchen environments, 3003 aluminum foil is largely used for wrapping foods, lining pans, or creating steaming packets that preserve flavor and nutrients during the cooking process. Its multifunctionality at home epitomizes industrial aspirations, as consumers demand convenience without sacrificing quality.

- Pharmaceutical and Medical Applications

Opting for aluminum foil in healthcare settings ensures the integrity and cleanliness of medications and medical instruments. The non-toxic and non-reactive nature of 3003 aluminum foil gives it an edge for producing pills and IV components that retain their efficacy without contamination. Its application extends to blister packaging, which suits the strict demands for cereal dosage scheduling.

- Electrical Insulation

Thanks to its excellent conductive properties combined with effective barrier functionality, 3003 aluminum foil is frequently used in electronic applications. Its versatility caters to the production of capacitors, transformers, and various insulating pieces, giving manufacturers a material with excellent electrical performance.

- Industrial and Specialty Fabrication

Industries take advantage of 3003 aluminum foil's structural integrity to create products like heat exchangers. Its high thermal conductivity accelerates heat transfer in areas like refrigeration, an essential quality for enhancing energy efficiency in cooling systems. Furthermore, its stain and dent resistance extend a reliable advantage in products exposed to external stressors.

- Decorative Uses

Finally, 3003 aluminum foil can also be enhanced or treated for decorative purposes. This functional aesthetic allows architects and designers to utilize it in innovations toward building materials, signage, and art installations requiring lightweight but resilient surfaces.