Mill finish aluminum coil foil 3003 aluminum alloy

Mill Finish Aluminum Coil Foil 3003 Aluminum Alloy: Unveiling the Unsung Foundation of Everyday Durability

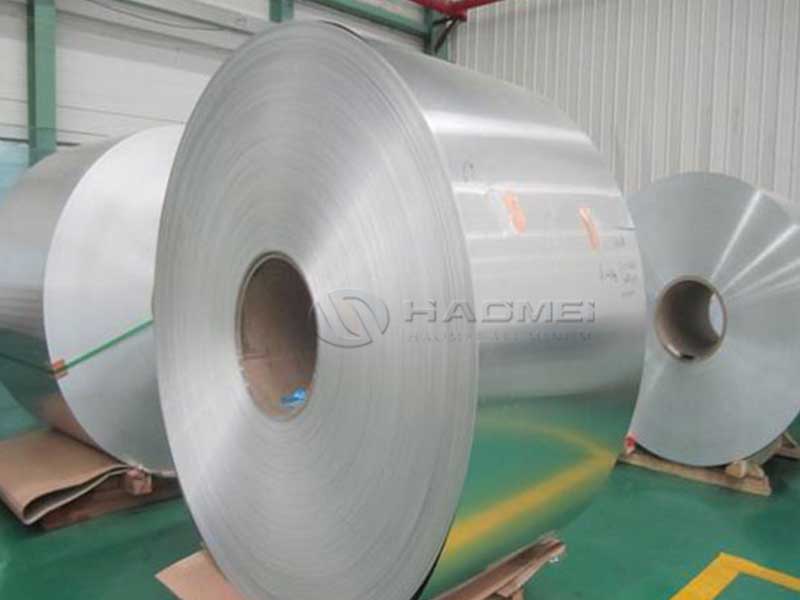

When we admire shiny appliances, sturdy cookware, or the reflective cladding on buildings, aluminum plays a silent yet pivotal role. Among its many forms, mill finish aluminum coil foil in 3003 aluminum alloy stands out as a versatile, practical, and reliable material rarely charged with the spotlight but quietly laying the groundwork for everyday durability.

What Is Mill Finish Aluminum Coil Foil?

Mill finish refers to the surface condition of aluminum immediately after it leaves the rolling mill. It is essentially the natural finish without any secondary treatments like polishing, anodizing, or painting. This finish is mildly textured, somewhat matte, revealing the true raw beauty of aluminum.

When rolled into coil foil form, aluminum—thinly sheeted in long continuous strips—becomes strikingly adaptable. Mill finish aluminum coil foil is both mechanically flexible and inexpensive to produce, answering the need for a foundation material upon which industrial creativity can build.

Why 3003 Aluminum Alloy?

3003 aluminum alloy is an aluminum-manganese composition known for its excellent corrosion resistance, moderate strength, and formability. Compared to pure aluminum (like 1100 alloy), 3003 carries added vigor without sacrificing lightweight benefits. It is magnetic-free, non-toxic, and highly recyclable.

Its balanced properties make 3003 the workhorse of operations requiring reliable endurance without premium cost. Often nicknamed the “general-purpose alloy," 3003 fills the role of an artisanal canvas in coil foil mill finish format, ready to take on countless manufacturing needs—from vents and ducting to cooking utensils and roofing sheets.

The Overlooked Charm of Mill Finish

We often associate aluminum’s role with its polished and painted appearances, but the mill finish merits appreciation in its own right. It preserves the metal’s genuine, unaltered texture, providing a tactile experience reminiscent of industrial origins.

In applications such as HVAC systems or food containers, this natural finish isn’t a casualty but a strategic asset. The subtle roughness improves adhesion when downstream coatings are applied, serves as an antimicrobial haven when paired correctly, and equals an ideal compromise between cost efficiency and functional aesthetics.

Sustainability and Lifecycle

Another particularly compelling aspect is the sustainability embodied in 3003 mill finish foil coils. Its ease of recycling due to minimal treatments plus outstanding corrosion resistance reduces lifecycle carbon footprint. Repair and repurposing flourish in such unchanged finishes — saving materials and energy while anchoring circular economy principles.

A Material with Infinite Potential

From manufacturing lines that build everyday electronic enclosures to artisan crafting high-quality signage or packaging, mill finish aluminum coil foil in 3003 alloy quietly empowers creators and engineers. Its combination of affordability, mechanical reliability, and environmental friendliness speaks ’loud’ to industries striving for smarter materials choices.

Explore the practical versatility and understated durability of mill finish aluminum coil foil made from 3003 aluminum alloy — an eco-friendly, general-purpose material trusted across industries for its strength, corrosion resistance, and cost-effectiveness.

https://www.alusheets.com/a/mill-finish-aluminum-coil-foil-3003-aluminum-alloy.html