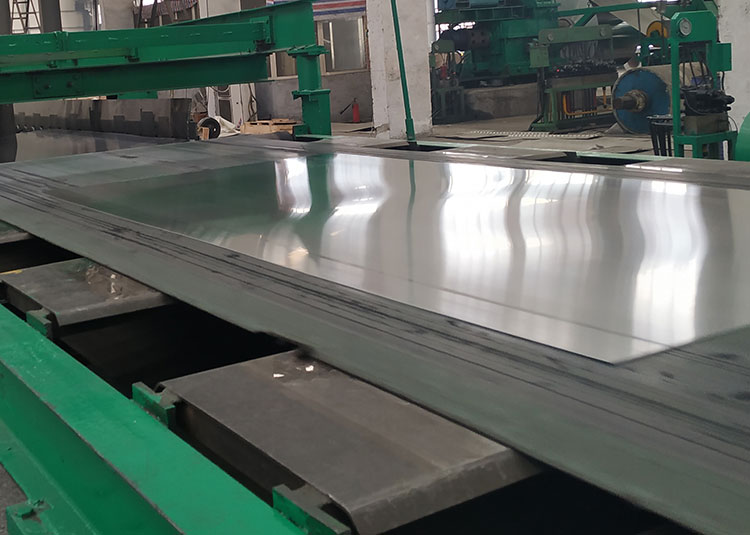

4x8 sheet aluminum plate

Harnessing Innovation: The Advantages of 4x8 Sheet Aluminum Plate

In the ever-evolving world of materials engineering, the 4x8 sheet aluminum plate stands out for both its versatility and performance. As an Aluminum Alloy Expert, I’d like to delve deeper into how these plates revolutionize various industries while elucidating their unique properties that set them apart.

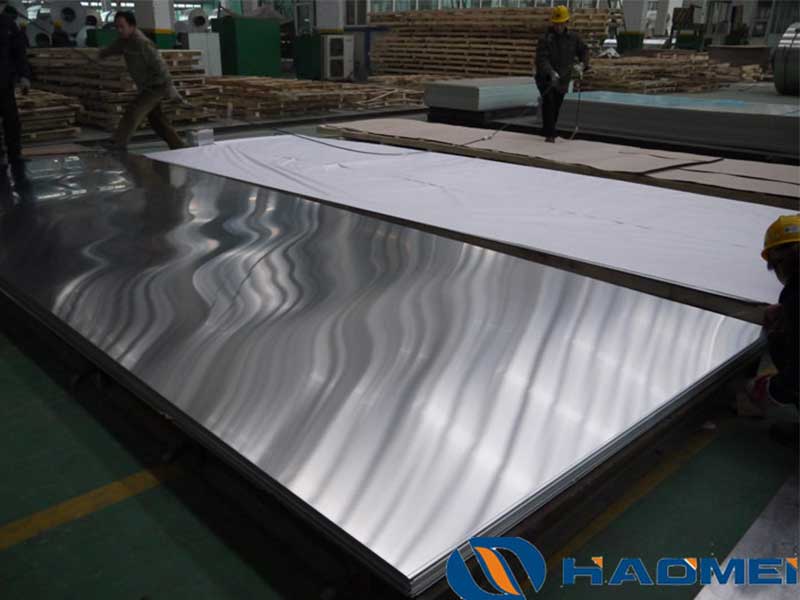

Working with 4x8 sheet aluminum plate daily reveals a fascinating interplay between material properties and practical limitations. The seemingly straightforward dimensions belie a significant challenge in handling: a single sheet weighs a considerable amount, demanding specialized equipment like overhead cranes or powered lift trucks for safe and efficient movement. Even minor imperfections in flatness, often present in larger sheets, become amplified during fabrication processes, leading to issues with press fitting, precise cutting, and ultimately, product quality. We've learned to meticulously inspect each sheet for warping or bowing, often employing shims and specialized jigs to compensate during machining. The sheer size also dictates optimized storage and workflow to prevent damage from stacking or accidental impacts.

Beyond handling, the 4x8 format impacts production planning significantly. Nested cutting patterns are crucial to minimize waste and maximize yield, requiring sophisticated software and skilled operators. The inherent flexibility of aluminum, while beneficial in some applications, can create challenges during welding or bending operations. We've encountered instances where sheets, despite rigorous quality control, experienced slight dimensional variations after heat treatment, necessitating adjustments in subsequent processes. the nuances of material behavior at this scale – its thermal expansion, susceptibility to scratches, and the potential for surface imperfections – is critical to consistently producing high-quality "Aluminum Plate" products.

Technical Specifications: Defining the Core

A typical 4x8 sheet aluminum plate has dimensions of 48 inches by 96 inches, providing a useful, standardized surface area that makes it a preferred choice among manufacturers, builders, and fabricators alike. These plates generally come in thicknesses ranging from 1/8 inch to 1 inch and can be found in a variety of alloys, the most popular being 6061 and 5052.

- Alloys and Properties:

- 6061 Aluminum Alloy: Renowned for its strength and excellent corrosion resistance, this alloy can also be easily welded. Ideal for structural applications, it supports innovations in automotive and aerospace fields.

- 5052 Aluminum Alloy: This alloy offers superb corrosion resistance and formability, making it perfect for marine environments and complex metal shapes.

these alloys and their distinct properties allows professionals to select the best 4x8 sheet aluminum plate that aligns with their project's requirements.

Unique Applications: Crafting Solutions

The usage of 4x8 sheet aluminum plates extends beyond conventional applications.

-

Custom Fabrication: Modern manufacturing allows for customization shared between CNC machining platforms and 4x8 aluminum plates. The plates are used extensively for brackets, extrusions, gearbox housings, and more, signifying their crucial capacity for adaptable engineering solutions.

-

Aerospace Advancements: With aerospace designs pushing for weight reduction coupled with high durability, the unique blend of lightweight properties and strength in aluminum plates leads manufacturers to favor them. For example, structural components crafted from 6061 plates can optimize fuel efficiency in aircraft, decreasing operational costs.

-

Marine Applications: Saltwater can severely damage most metals, but the excellent corrosion resistance of 5052 aluminum alloy contributes to its popularity in boat construction and frameworks for docks. Unique treatments can give 4x8 sheet plates additional resilience, ensuring longevity in harsh conditions.

-

Sustainable Architecture: Urban environments now reference sustainability across design projects. Aluminum's recyclability combines positively with these architectural visions, providing a populist yet practical approach for bolstering eco-focused initiatives in construction.

Proficiency Techniques to Maximize Utilization

To fully exploit the benefits of 4x8 sheet aluminum plates, one must embrace ideal machining, proper handling, and bending techniques dictated by each application’s requirements. It's critical to incorporate correct cutting tools and settings on CNC machines to deliver clean, accurate processes, minimizing waste and errors in production cycles.

Investing in advanced surface treatments, such as anodizing and powder coating, can dramatically enhance aesthetics as well as durability, sealing surfaces against other contaminants and versions of corrosion like pitting.

Embrace the Evolution

In conclusion, the adaptability of the 4x8 sheet aluminum plate position it as a pivotal material paving the way for future possibilities. Its formidable array of properties—combined with ongoing advancements in fabrication and engineering practices—offers an unparalleled advantage for anybody discussing modern materials.

Navigating through different industries, including automotive, aerospace, marine, and architecture, demonstrates how the unique characteristics of these plates unlocks new avenues of design and innovation. With industry professionals tapping into cutting-edge knowledge along with the emerging trends surrounding aluminum alloys, the best is yet to come in materials solutions.