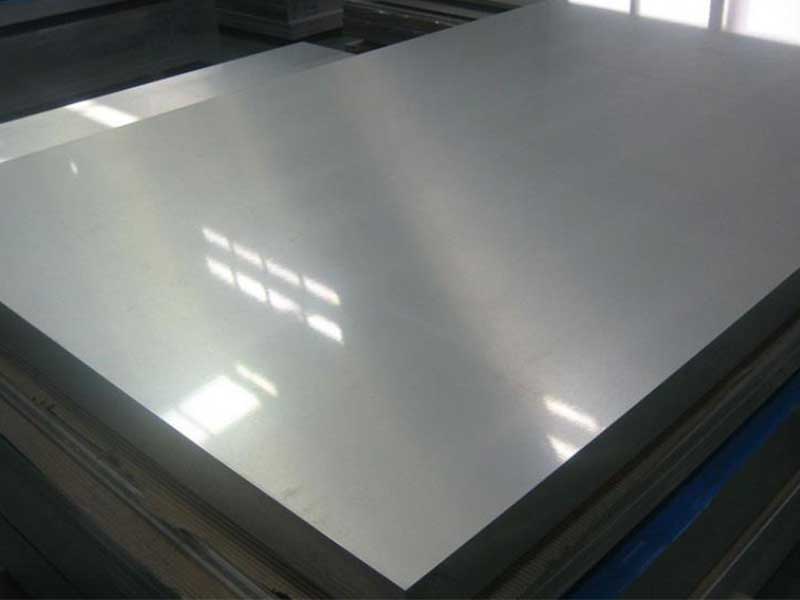

Aluminum sheet Alloy 1100 1050 O h14 h24

Aluminum alloys are celebrated for their outstanding properties, lightweight nature, and affordability. Among the myriad of options, Aluminum Alloy 1100 and 1050 sheets is know due to their corrosion resistance, formability, and improved mechanical strength.

Understanding Aluminum Alloy 1100 and 1050

What is Aluminum Alloy 1100?

Aluminum Alloy 1100 is a commercially pure aluminum with excellent corrosion resistance, high thermal and electrical conductivity, and good workability. This alloy is approximately 99 percent pure, resulting in properties that make it ideal for various applications where minimal mechanical stress is involved.

What is Aluminum Alloy 1050?

Aluminum Alloy 1050, while also a commercial-grade alloy, possesses slightly higher strength than Alloy 1100, making it another excellent option for sheet metals. Typically composed of 99.5 percent pure aluminum, Alloy 1050 offers remarkable corrosion resistance, workability, and excellent weldability.

Temper Designations: O, H14, and H24

Understanding temper designations is crucial for properly utilizing aluminum sheets. The temper indicates the material's heat treatment state and provides insight into its properties.

-

O Temper (Annealed): Temper O refers to aluminum that has been annealed to achieve maximum softness. Both alloys 1100 and 1050 in this temper are easily stretch-formed and fabricated with minimal risk of fracturing.

-

H14 Temper: H14 temper indicates that the alloy has been strain-hardened (processed to bolster its strength) and partially annealed. This temper offers enhanced strength characteristics while still maintaining reasonable ductility (approximately 50% to 99% yield strength).

-

H24 Temper: H24 indicates strain-hardened and partially annealed aluminum, resulting in a product that offers a good balance of strength and formability. This temper provides better mechanical properties than H14 while remaining ideal for roller forming applications.

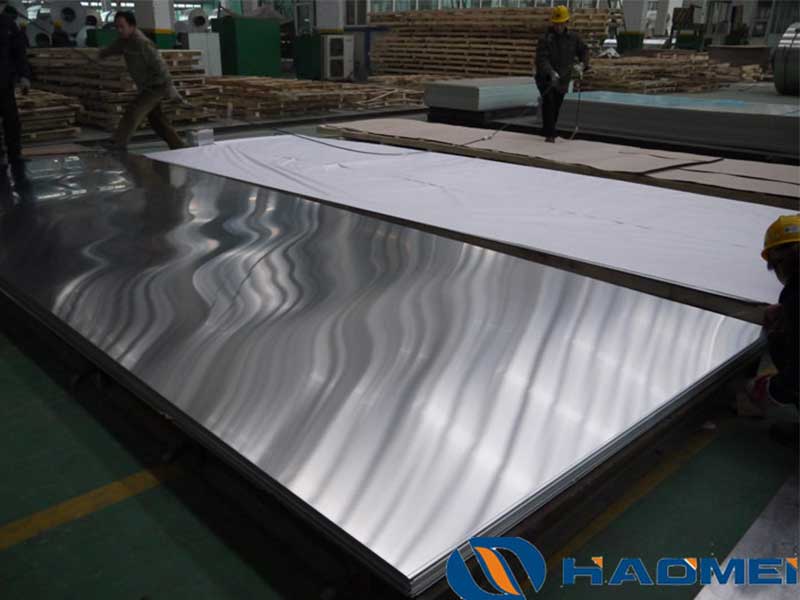

Features of Aluminum Alloy 1100 and 1050 Sheets

1. Lightweight and High Strength

Both Alloy 1100 and 1050 are lightweight compared to steel and other metals, making them popular choices in applications where weight reduction is critical, such as automotive manufacturing and aerospace.

2. Exceptional Corrosion Resistance

Due to their high purity levels, both alloys display exceptional resistance to corrosion, making them suitable for outdoor applications or environments with moisture. This durability extends the life of products and structures made from these alloys.

3. Excellent Workability

All aluminum tempers, especially O, H14, and H24, are recognized for excellent workability. They can be easily formed, welded, and machined into intricate shapes, resulting in reduced fabrication costs.

4. Thermal and Electrical Conductivity

Compared to many other materials, aluminum alloy sheets exhibit high thermal and electrical conductivity. Alloys 1100 and 1050 are often used in electrical and heat transfer applications as a result.

Applications of Aluminum Alloy 1100 and 1050

A. Food and Chemical Industries

The food and chemical industries utilize Aluminum Alloy 1100 for making lightweight containers, heat exchangers, and storage tanks due to its excellent corrosion resistance and ability to withstand various chemicals.

B. Architectural Applications

Both Alloy 1100 and 1050 lend themselves well to diverse architectural elements, including wall and roof panels, decorative trims, and signage due to their attractive finish and great workability.

C. Electrical Applications

With their high conductivity, these alloys are often used in the manufacturing of electrical components such as bus bars, heat sinks, and electrical connections.

D. Automotive Applications

The automotive industry employs Aluminum Alloy 1050 in structural components and parts requiring a combination of lightweight and strength. H14 and H24 tempers are preferred in components subject to higher mechanical loads.

E. Heat Exchangers

Aluminum sheets treated in temper O are ideal candidates for use in heat exchangers due to their superior ability to dissipate heat, contributing to better functionality in various applications.

https://www.alusheets.com/a/aluminum-sheet-alloy-1100-1050-o-h14-h24.html