5083 Aluminum Sheet 2mm 3mm 4mm

The aluminum alloy series 5000, particularly 5083, stands out in numerous industrial applications for its versatility and robustness. While various home improvement bars or construction materials grace the market today, 5083 Aluminum Sheet remains a favored choice for professionals across myriad industries.

5083 Aluminum Alloy

5083 is categorized under the non-heat-treatable series, possessing significant strength and excellent resistance to corrosion, particularly against seawater. Primarily made of aluminum, magnesium, and small portions of manganese, 5083 strikes the perfect balance between formability, resistance, and anodizing potential, making it suitable for various environments.

Working with 5083 aluminum sheet in 2mm, 3mm, and 4mm thicknesses is a daily reality for us. What strikes me most isn't just its strength-to-weight ratio, which is crucial for many of our marine and transportation applications, but the nuances in its machinability at these varying thicknesses. The 2mm sheet, while easier to form and bend, can be more prone to tearing if not handled carefully during processes like punching or stamping. The thicker 3mm and 4mm sheets require more powerful tooling and careful consideration of cutting speeds to avoid excessive heat buildup and distortion. We've fine-tuned our processes over time to optimize these operations, leading to minimal waste and consistently high-quality finished products. The difference in material handling alone is noticeable; the thinner sheets demand more attention to prevent scratching and bending during transport and storage.

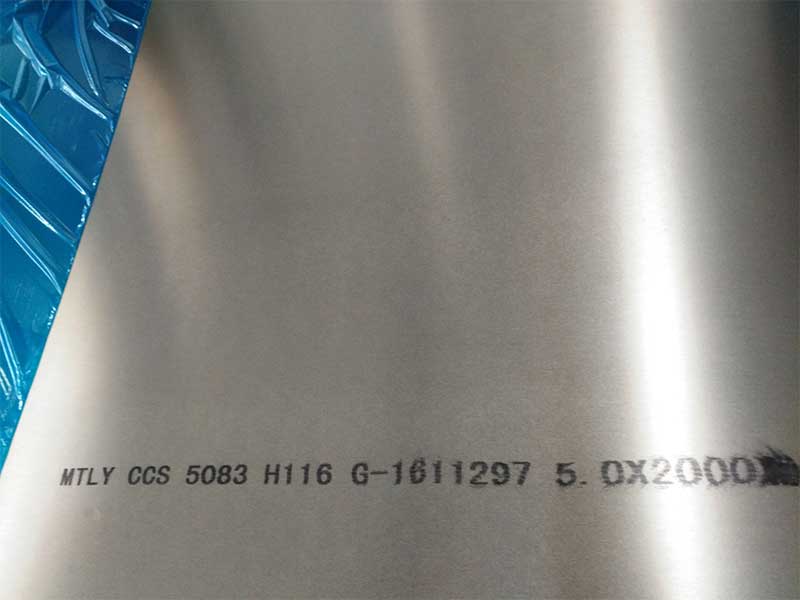

Beyond the technical aspects, I've noticed a growing demand for traceability and certification. Our clients, particularly in aerospace and shipbuilding, need stringent documentation proving the sheet's alloy composition and conformity to relevant standards. This pushes us to maintain meticulous records and invest in advanced quality control systems. It’s rewarding to see the final product, knowing the stringent quality control we've implemented, knowing that our 5083 aluminum sheet, whether it’s a thin 2mm panel or a robust 4mm plate, will contribute to reliable and

Thickness Matters: The Choice Between 2mm, 3mm, and 4mm

Thickness is a pivotal consideration when selecting an aluminum sheet for any application.

2mm 5083 Aluminum Sheet

The 2mm thickness is optimal for applications where lightweight and flexibility are vital. It is easier to handle and enables intricate designs. Auto cover panels presented in automotive assembly or bulk transport elements frequently use 2mm sheets due to their lower weight. It provides an excellent combination of density and durability, thus ideal for aesthetically pleasing yet challenging designs.

3mm 5083 Aluminum Sheet

Transitioning to the 3mm variant, this thickness marks an equilibrium between strength and formability. It can withstand moderate mechanical pressures and is frequently used in marine and transportation applications — particularly in constructing boat hulls. While maintaining sufficient weight and rigidity, it can also allow for some flexibility, making the 3mm 5083 sheet extensively popular among builders needing a balance of convenience and power.

4mm 5083 Aluminum Sheet

At 4mm, strength takes center stage. This thickness excels in environments requiring advanced stress management. It competes in demanding fields — like the construction of structural components and heavy-duty aircraft fittings. The robust toughness of the 4mm 5083 aluminum sheets enables them to endure the strenuous conditions of such applications, serving effectively in situations that portray severe dynamics or vibration.

Benefits of Using 5083 Aluminum Sheets

Corrosion Resistance

The ideal alloying elements found in 5083 aluminum result in remarkable corrosion resistance, making it highly aligned for marine environments or any application involving exposure to moist or salt-laden conditions.

Excellent Workability

While echoing the qualities of higher purity aluminum, 5083 offers groundbreaking ease of manufacturability while still delivering countless aperture cut-outs suitable for specularity.

Sustainably Resilient

Mechanical attributes of 5083 bring forth sophisticated fracture resistance — especially pronounced in sheets adopted across diverse platforms. Reducing failure risk is critical to industries manufacturing structuring elements outfitted for multifaceted stresses and challenges.

Effective Anodization.

An incredible feature of the 5083 series is its ability to undergo anodization processes, allowing for enhanced visual reach while also imparting a further layer of protection. Works pertaining to aesthetics — either decorative or ensuring longevity of components translate smoothly with modern anodization processes for aligned longevity.

Suitable Applications of 2mm, 3mm, and 4mm 5083 Aluminum Sheets

- Marine constructions like yacht, shipbuilding — thanks to the sheets' corrosion resistance.

- Transportation Equipment including painted display areas, automobile parts, and commercial freight advancements.

- Architectural projects that marry both architectural aesthetic value alongside structural prowess.

https://www.alusheets.com/a/5083-aluminum-sheet-2mm-3mm-4mm.html