Aluminium Sheet 1050, 1060, 1070 3003 for Traffic

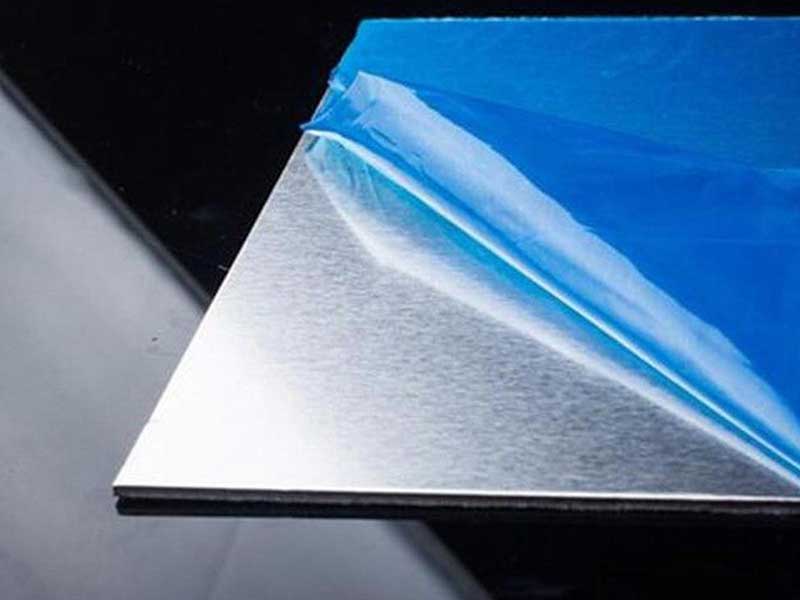

Aluminum sheets are an essential material in various industries, offering excellent properties like light weight, corrosion resistance, and durability. Within the vast range of aluminum alloys, species like Aluminum Sheet 1050, 1060, 1070, and 3003 stand out for their unique characteristics and applications.

Understanding Aluminum Alloys

Aluminum alloys are divided into two primary categories: wrought and cast. The numbers associated with each alloy indicate the specific type, with the first digit representing the alloy series. For instance, Aluminum Sheets in the 1xxx series, like 1050, 1060, and 1070, are pure aluminum, known for their excellent conductivity and corrosion resistance. Meanwhile, the 3003 alloy belongs to the 3xxx series, mainly characterized by its manganese content.

Aluminum Sheet 1050

Aluminum Sheet 1050 is recognized as one of the purest aluminum alloys, containing about 99.5% aluminum. Its high conductivity makes it an optimal choice for electrical applications, including transformers and capacitors. Additionally, Aluminum Sheet 1050 exhibits superior corrosion resistance, making it suitable for environments exposed to moisture and other corrosive elements. Common applications of 1050 aluminum sheets include:

- Electrical conductors

- Food processing equipment

- Chemical and petrochemical applications

Aluminum Sheet 1060

Similar to 1050, Aluminum Sheet 1060 boasts a purity level of approximately 99.6% aluminum, providing enhanced mechanical properties due to its slight alloying elements. This aluminum sheet is often chosen for its excellent weldability and fabrication properties, making it widely used in bus bars, wiring, and chemical processing. Other key applications include:

- Aerospace components

- Heat exchangers

- Medical equipment

Aluminum Sheet 1070

Aluminum Sheet 1070 is known for its exceptional purity as well, with aluminum content exceeding 99.7%. This alloy is notably chosen when high conductivity, weldability, and ductility are essential requirements. Applications that benefit from its composition include:

- Electrical and thermal applications

- Reflective applications such as light fixtures

Aluminum Sheet 3003

Aluminum Sheet 3003 is an alloy that offers higher strength than its 1xxx counterparts due to the addition of manganese (approximately 1.0% to 1.5%). This unique property makes 3003 a popular choice for a range of applications, from cooking utensils to storage tanks. The alloy’s good workability and corrosion resistance further enhance its usability. Common applications of Aluminum Sheet 3003 include:

- Cookware and food processing

- Residential siding

- Chemical equipment

Comparison and Application Insights

While Aluminum Sheets 1050, 1060, and 1070 are renowned for their high conductivity and corrosion resistance, Aluminum Sheet 3003 stands out for its strength and versatility. Your choice may depend on the specific requirements of your project:

- For electrical applications: Consider using 1050 or 1060 for their superior electrical conductivity.

- For structural strength: Aluminum Sheet 3003 may be the better choice due to its strengthened properties.

- For food-related products: Both 3003 and 1050 are excellent options, but the former tends to excel in durability.

https://www.alusheets.com/a/aluminium-sheet-1050-1060-1070-3003-for-traffic.html