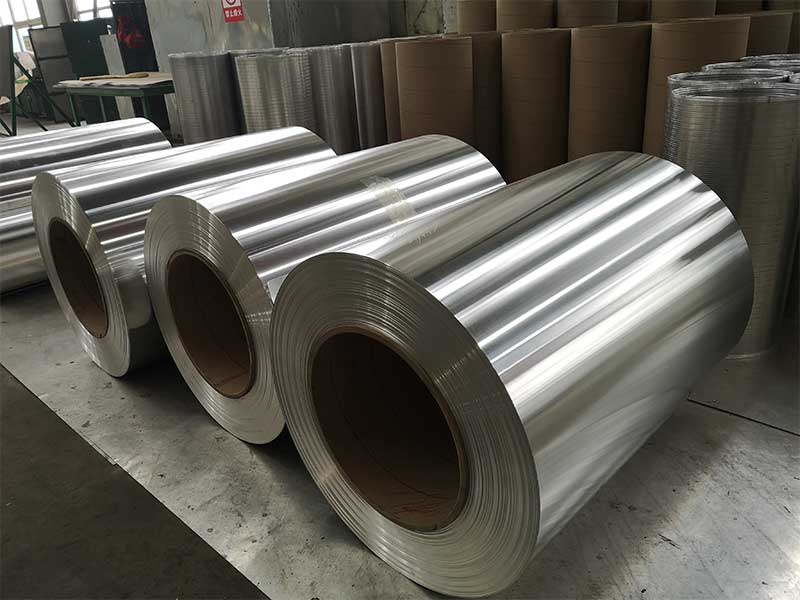

Aluminum coil 1060 1100 3003 5052 Ho H14

Aluminum coils, especially in grades such as 1060, 1100, 3003, and 5052 Ho H14, play a significant role in numerous industrial applications, owing to their lightweight, durability, and corrosion resistance. Grasping the unique features and applications of these aluminum alloy grades enables businesses and individuals to make informed selections tailored to specific needs.

Features of Aluminum Coils

1. Aluminum Coil 1060

The 1060 aluminum coil is known for its outstanding corrosion resistance and excellent conductivity, making it highly beneficial for electrical applications. This alloy typically contains 99.6% aluminum, leading to remarkable formability.

Applications: Commonly used in manufacturing chemical and food processing equipment, as well as in electrical applications such as power lines and capacitors.

2. Aluminum Coil 1100

Overall, the 1100 aluminum coil boasts significant workability and enhanced corrosion resistance. It contains 99% aluminum and has excellent forming characteristics. This alloy is suited for a range of cold working processes and can be polished to achieve a brilliant finish, particularly suitable for consumer cooking utensils and heat exchangers.

Applications: Predominantly used in kitchen equipment, food container packaging, and heat exchangers due to its malleable properties.

3. Aluminum Coil 3003

The 3003 aluminum coil combines good workability, durability, and corrosion resistivity, thanks to its melding of aluminum with 1-2% manganese. This grade ensures excellent machinability, making it valuable in manufacturing and repair applications.

Applications: Commonly found in components such as storage tanks, decorative exterior surfaces, and housing for medical equipment due to its strength and lightweight nature.

4. Aluminum Coil 5052 Ho H14

The 5052 Ho H14 aluminum coil is among the most versatile and widely used non-heat treatable alloys. Characterized by its exceptional corrosion resistance and tensile strength, it is impervious to seawater and salt spray eradication.

Applications: Popular in marine environments (like boat hulls and offshore structures), automotive fuel tanks, and pressure vessels due to their durability and minimalist weight.

https://www.alusheets.com/a/aluminum-coil-1060-1100-3003-5052-ho-h14.html