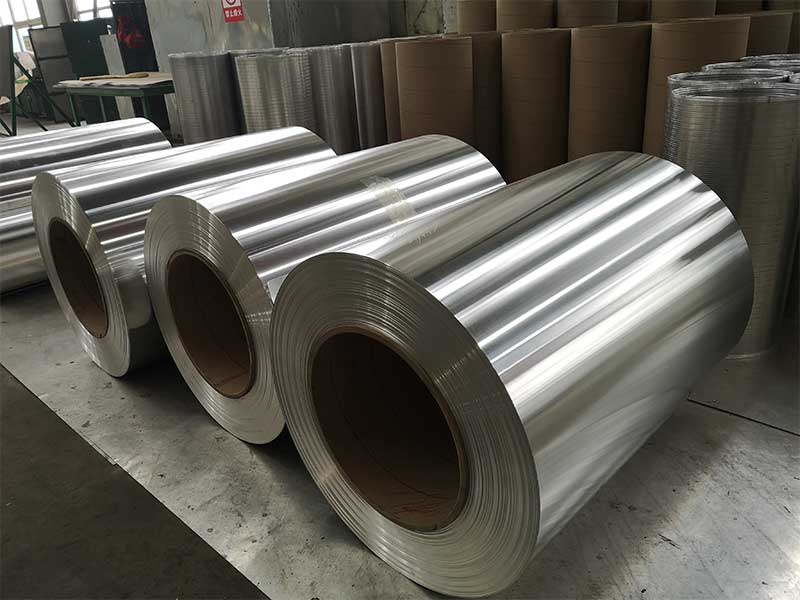

Astm b209 alloy 5052 aluminium coil

The ASTM B209 standard specifies the specifications for aluminum and aluminum alloy sheets and plates for general applications. Among the coveted materials is Alloy 5052, which is renowned for its unique properties that enhance its functionality across various domains.

Features of ASTM B209 Alloy 5052 Aluminum Coil

-

Excellent Corrosion Resistance: One of the most significant attributes of Alloy 5052 is its remarkable resistance to corrosion. This quality makes it particularly suitable for marine and industrial environments that expose materials to harsh weather conditions, eliminating the need for protective coatings in many applications.

-

High Fatigue Strength: Alloy 5052 exhibits superior fatigue performance compared to several other aluminum alloys. This tailors its usage in areas subject to dynamic loading, including vehicles and structural components.

-

Workability and Formability: This alloy is versatile in terms of shaping, capable of being cold-worked and readily welded without compromising its strength. This characteristic facilitates its integration into a variety of products—whether in form of complex shapes like stamped parts or straightforward sheets and coils.

-

Non-Heat Treatable Alloy: Unlike many aluminum alloys, 5052 is not heat-treatable. Instead, it can gain strength from work hardening. This feature provides reliability for applications requiring continuous strength while reducing risks associated with stress-corrosion cracking.

-

Good Ductility and Malleability: With excellent elongation properties, Alloy 5052 can easily be formed into intricate parts, enabling diversified functionalities in various sectors.

Applications of ASTM B209 Alloy 5052 Aluminum Coil

Due to its impressive characteristics, ASTM B209 Alloy 5052 finds wide applications across multiple industries:

1. Automotive Industry:

Aluminum alloys are extensively employed in the automotive sector to improve vehicle efficiency without compromising safety. The lightweight yet strong nature of 5052 alloy makes it ideal for manufacturing vehicle body panels, fuel tanks, and other components that require excellent durability and resistance to corrosion.

2. Marine Applications:

Given its notable resistance to saltwater corrosion, Alloy 5052 is predominantly utilized for shipbuilding. Marine components such as hulls, docks, and marine structures significantly benefit from this alloy’s durability, ensuring longevity and structural integrity in demanding environments.

3. Construction Industry:

In construction, ASTM B209 Alloy 5052 is often used in architectural applications. From building facades to various types of roofings, its lightweight nature, strength, and easy formability make it a favorite choice. The ability to anodize aluminum further enhances its aesthetic and protective properties.

4. Food and Beverage Packaging:

The alloy also proves beneficial in food-grade applications due to its non-toxic nature. Alloy 5052 is often used in manufacturing food containers and equipment where sanitation and corrosion resistance are vital.

5. Pharmaceutical Industry:

Alloy 5052's resistance to various chemicals aids its special role in the pharmaceutical sector, particularly in the creation of equipment that must maintain high purity standards while preventing contamination.

https://www.alusheets.com/a/astm-b209-alloy-5052-aluminium-coil.html