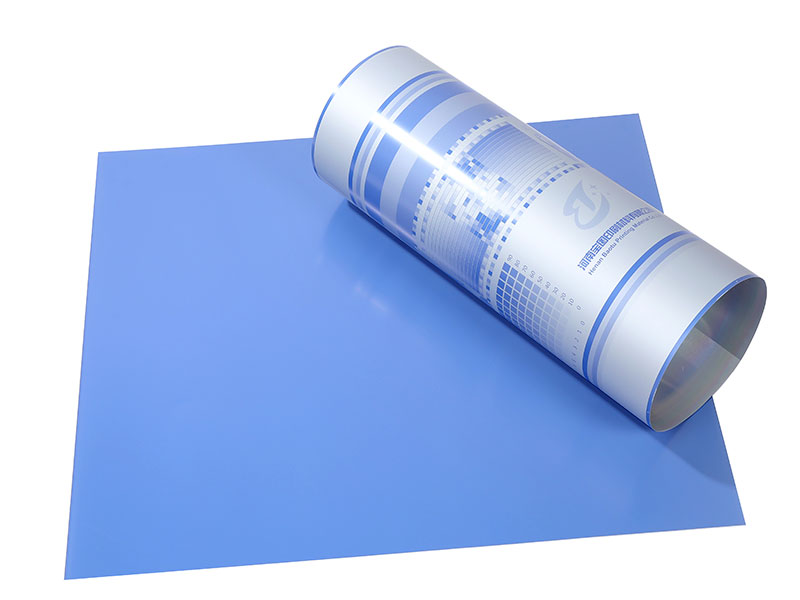

Double layer CTP Plate

Unveiling the Dual Wonders of Double Layer CTP Plates: Features and Applications

The world of printing technology is constantly evolving, driven by the need for higher quality output and increased efficiency. At the forefront of these advancements is the Double Layer CTP (Computer to Plate) Plate—a game-changer that offers unprecedented benefits for printers and manufacturers alike.

From my experience working with Aluminium CTP (Computer-to-Plate) plates, the shift towards double-layer plates represents a significant advancement, primarily in terms of print longevity and improved resistance to scratches and wear. Single-layer plates, while cost-effective, often show degradation after a certain number of print runs, leading to inconsistencies in image quality and increased waste. The double-layer structure, usually consisting of a harder top layer for image fidelity and a more robust base layer for durability, significantly mitigates this. We've seen a notable reduction in plate replacement frequency since adopting double-layer plates, leading to substantial cost savings in the long run, despite the slightly higher initial investment. Furthermore, the improved scratch resistance minimizes downtime caused by damaged plates during handling and processing.

However, the implementation of double-layer CTP plates isn't without its challenges. The processing parameters, including exposure time and developer chemistry, need meticulous adjustment to achieve optimal results. Improper processing can lead to uneven development, causing image defects and compromising print quality. Moreover, the disposal of double-layer plates requires careful consideration, as the different layers may necessitate separate recycling or waste management streams. We've had to invest in additional training for our operators to ensure consistent and efficient processing of these more complex plates, and implement new waste management protocols to meet environmental regulations. Careful calibration and ongoing monitoring are crucial for maximizing the benefits of this technology.

What is a Double Layer CTP Plate?

Before delving into its implications, it’s essential to understand what constitutes a Double Layer CTP Plate. At its core, this plate employs a dual-layer construction, composed of a photopolymer surface that allows for higher sensitivity and adaptability when exposed to light. This structural innovation lies at the heart of its many advantages.

Exceptional Features of Double Layer CTP Plates

-

Enhanced Image Quality: One of the standout features of double layer CTP plates is their capacity to deliver superior print quality. The dual structure allows for better ink adhesion and more precise image reproduction. Fine details and gradients retain their clarity, leading to vibrant, professional-grade prints that satisfy even the most discerning clients.

-

Improved Printing Speed: The efficiency of double-layer CTP plates shines through in their quick processing capabilities. The photopolymer layers can be exposed and developed more rapidly compared to traditional counterparts, reducing downtime in commercial print runs. In a competitive environment where time is of the essence, this feature notably influences a business's bottom line.

-

Longevity and Durability: These plates is know for their robust durability, capable of withstanding multiple printing cycles without degradation. The metal composition of the underlayer provides structural stability while minimizing issues like plate wear and image loss over time. This longevity translates to reduced production costs and a flatter learning curve for printing teams.

-

Versatility Across Substrates: Double layer CTP plates excel in compatibility, easily accommodating a variety of substrates, from glossy stock to matte finishes. This versatility provides printers with the flexibility to expand their service offerings without the necessity of frequent changes to equipment or processes.

-

Eco-friendly Advantages: With global sustainability efforts on the rise, double layer CTP plates replenish the landscape of eco-friendly practices in printing. By minimizing the use of chemicals typically required for processing traditional plates, they promote a greener operation—a win-win for companies looking to improve their environmental footprint.

Applications of Double Layer CTP Plates

The versatile nature of double layer CTP plates paves the way for broad applications across various industries. Here are the segments leading the charge:

-

Commercial Printing: players in the commercial print industry utilize double layer CTP plates for catalogues, magazines, and promotional materials. Their ability to handle intricate designs at high speed aids printers in generating high-quality materials promptly.

-

Packaging Industry: With the packaging market thirsting for striking visuals and accurate colors, double layer CTP plates come to the forefront. They play a crucial role in the production of labels, cartons, and flexible packaging solutions where detail is paramount.

-

Publishing: Publishers benefit from less spoilage and downtime when transitioning through temperamental processes thanks to the swift output capabilities and reliability of imaging. Whether producing books or periodicals, quality and efficacy never take a backseat.

-

Textile Printing: Interestingly, textile printing companies have also found their place in utilizing these CTP plates for superior designs in fashion where precision is everything. Double layer plates open doors to more elaborate and colorful prints that captivate consumers.