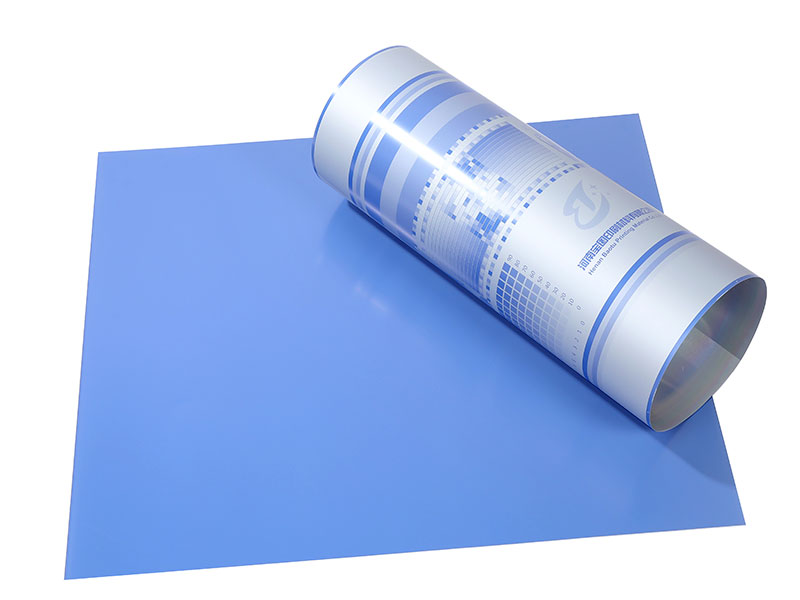

Printing Plate Aluminum Plate Thermal Positive CTP

In the fast-paced world of printing, efficiency, quality, and sustainability are paramount. The evolution of printing technologies has given birth to many solutions capable of meeting these demands, and one of the standout innovations is the Printing Plate Aluminum Plate Thermal Positive Computer-to-Plate (CTP) system.

Thermal Positive CTP Technology

At its core, Thermal Positive CTP uses high-quality aluminum plates, which are essential for producing sharp, vibrant images on paper. The “thermal” aspect refers to the plate's exposure to laser heat, which allows for precision imaging without the need for intermediary films. This shift from traditional methods to this groundbreaking approach not only saves time but minimizes environmental impact.

Working with thermal positive CTP plates for aluminum printing plates, I've found that the to consistent, high-quality output lies in meticulous control of the imaging process. Slight variations in laser power, plate temperature, or even the ambient humidity can significantly affect the exposure and subsequent development, leading to inconsistent ink transfer and ultimately, print defects like dot gain or plate scumming. We've seen firsthand how optimizing the laser's power profile for specific plate types and adjusting processing parameters based on environmental conditions dramatically improves the lifespan and performance of the plates. the interplay between these factors is crucial, and regular calibration and maintenance of the imaging system are non-negotiable.

Beyond the imaging process, the pre-press preparation is often overlooked. The cleanliness of the aluminum plate itself is paramount. We've discovered that even seemingly minor surface imperfections or residues can interfere with the laser's ability to accurately expose the photosensitive layer, resulting in inconsistent image quality. Implementing robust cleaning protocols, including pre-exposure cleaning and the use of specialized cleaning agents, has drastically reduced the instances of plate defects. Furthermore, proper storage of plates before and after exposure is critical to preventing degradation and ensuring consistent results from batch to batch. Careful attention to these seemingly minor details often yields the greatest improvements in overall plate quality and print fidelity.

Unique Features that Make a Difference

-

High Resolution and Color Accuracy: One of the largest challenges printers face is maintaining image quality. The technology utilized in Thermal Positive CTP establishes a remarkable equilibrium between resolution and color fidelity. The use of thermal technology ensures that the images produced are incredibly sharp and accurate. Each newspaper, flyer, or brochure that leaves the press has the potential to make a significant impact.

-

Sustainable and Cost-Effective: Adopted widely as part of environmentally friendly practices, Aluminum Plate Thermal Positive CTP eliminates the need for chemical processing that is prevalent in conventional printing. As a result, it significantly reduces water consumption and chemical waste—addressing sustainable print production while also decreasing operating costs.

-

Fast Turnaround and Efficiency: In a world where time equates to money, the rapid print turn-around stemming from Thermal Positive CTP processing can revolutionize businesses. By eliminating cumbersome steps such as film creation and darkroom processing, printers can expedite their workflows, leading to swifter job completion without compromising standards.

-

Enhanced Longevity of Printing Plates: The durability of aluminum plates is one of the finer nuances worth emphasizing. These plates can withstand pulling more runs than their counterparts, which makes them ideal for high-volume production. This feature not only adds to efficiency but also is beneficial from a cost-analysis standpoint, as fewer plates need to be fabricated for the same tasks.

-

Versatility Across Applications: The true beauty of Printing Plate Aluminum Plate Thermal Positive CTP lies in its versatility of applications. Whether it’s high-end packaging, commercial printing, or general production runs, this technology adapts seamlessly to different materials and print formats. From fashion magazines to corporate brochures and specialized packaging, the thermal CTP method promises pristine quality and customizable production runs.

Real-World Applications

-

Commercial Print Shops: In the competitive environment of commercial printing, the capability to deliver fast results without sacrificing quality is invaluable. Whether a project requires short-run magazines or promotional material, Thermal Positive CTP can enhance quality and efficiency, appealing to a broad customer base.

-

Packaging Production: With brand owners increasingly demanding high-quality, visually striking packages, the demand for precise imaging in packaging is at an all-time high. The Thermal CTP method allows designers to produce vivid colors and a range of patterns that capture buyer attention on crowded shelves.

-

Art and Photography: Artists and photographers rely heavily on precise color reproduction. Thermal Positive CTP provides an excellent platform to achieve that, delivering significant detail and nuance found in individual interpretations—whether framing artwork for galleries or high-end printed portfolios.

-

Newspapers and Periodicals: Despite the rise of digital media, traditional avenues such as newspapers still leverage cutting-edge technologies. The rapid turnaround time afforded by Printing Plate Aluminum Plate Thermal Positive CTP technology reflects well on time-sensitive publication rates while maintaining crisp imagery on every page.

In conclusion, the Printing Plate Aluminum Plate Thermal Positive CTP stands as a shining example of where innovation meets practicality. By its unique features and diverse applications, those in the printing industry can harness its power to not only enhance production capacities but also embrace a more sustainable and quality-driven future. As the print world continues to evolve, adopting such advanced technologies will be crucial not only to staying competitive but to redefining industry standards altogether.

https://www.alusheets.com/a/printing-plate-aluminum-plate-thermal-positive-ctp.html