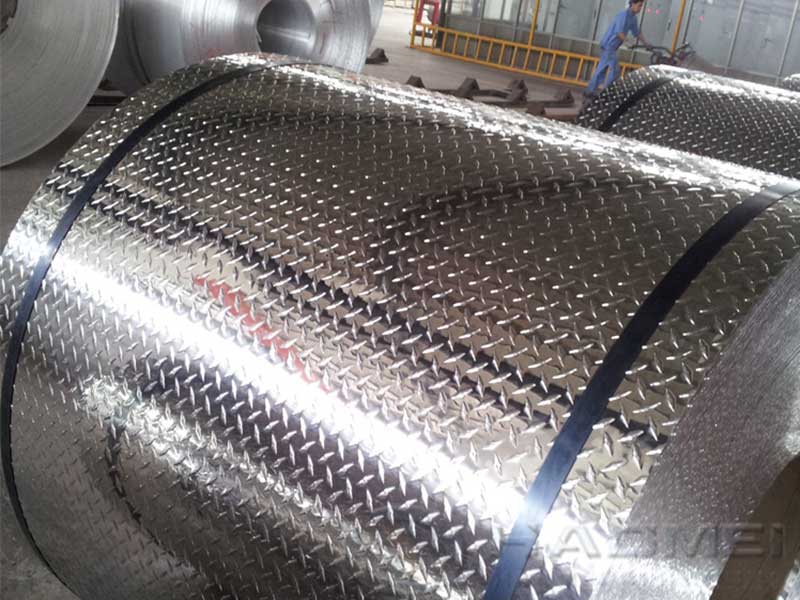

10 Gauge 3003 Embossed Aluminium Sheet

In the vast landscape of agricultural, industrial, and creative applications, the 10 gauge 3003 embossed aluminum sheet stands out not just for its structural integrity, but for its remarkable versatility and aesthetic appeal. As a unique material, it combines durability, lightweight characteristics, and excellent formability—all while offering a distinctive appearance that can easily elevate the design of finished products.

the Technical Details: The Core Phenomenon

Before diving into its myriad applications,( \textbf{let's conceptualize some of its defining characteristics.}) The 3003 alloy, often distinguished by its addition of 1.2% manganese, is known for its excellent corrosion resistance and superior workability. At 10 gauge—in which one gauge is equal to about 0.135 inches, resulting in a thickness of approximately 0.1345 inches—this material provides an optimum balance between strength and protection without sacrificing lightweight properties.

The embossed finish not only enhances aesthetics but enhances anti-slip performance, making it practical in various settings.

The Functional Beauty Factor

While hardness and durability make the 3003 embossed aluminum sheet a go-to for infrastructural applications, its striking aesthetic transforms it into a feature element for creative projects. Unlike enamel or other finishes, embossed aluminum gives depth and tactile appeal without shedding under normal wear:

-

Architectural Applications: From decorative panels to insulated wall coverings, the natural beauty and significant structural advantages of the 10 gauge 3003 embossed aluminum sheet empower architects and builders alike. Architectural firms underpin intricate designs with wraps that partially reflect light, creating an illusion of shifting shades throughout the day, which in turn can beautify both commercial and residential properties.

-

Transport and Automotive Industry: In the realm of taht fine balance between style and utility, the automotive sector benefits immensely from this aluminum beauty. Used extensively for interior paneling and crafting drum covers, embossed sheets not only add flair, but also secure components against everyday wear and tear. Plus, the intrinsic lightweight quality results in fuel efficiencies, making cars not just stylish but functional.

-

Industrial Safety: Most prominently renowned for their use on alternative route applications and in hazardous contexts. Thus the embossed sheet enhances traction, ensuring a safer work environment. Whenever slip-resistance is vital—ramp beds on trucks, in busy walk-in layers along entrances, or around troublesome industrial machinery—the engagement principle of embossed surfaces becomes an invaluable aspect of design.

-

Signage and Displays: Where visual impact meets durability—trade shows, exhibitions, and resale shops—using the 10 gauge option liberates creative advertisement impulses. Designed with precision-mined systems as digital prints catch the consumer’s eye memorably against the shiny acidity of an ordered 3003 look, it amplifies branding awareness, enhancing the effectiveness visually satisfying solutions for outreach.

-

Custom Fabrication and Home Decor: Beyond the pragmatic applications, hobbyists and artisans tremble with limitless DIY capabilities, from can experimental furniture industry innovators as tracked cosplays and multiture relief systems entice workings for on-the-table finales, it simultaneously entertains through impeccable styling alive with charming finishing curtains. Such functional beauty tends to pull together tonal excellence around conventional masking frameworks resonates like quality-grade mentorship.

https://www.alusheets.com/a/10-gauge-3003-embossed-aluminium-sheet.html